Case Study

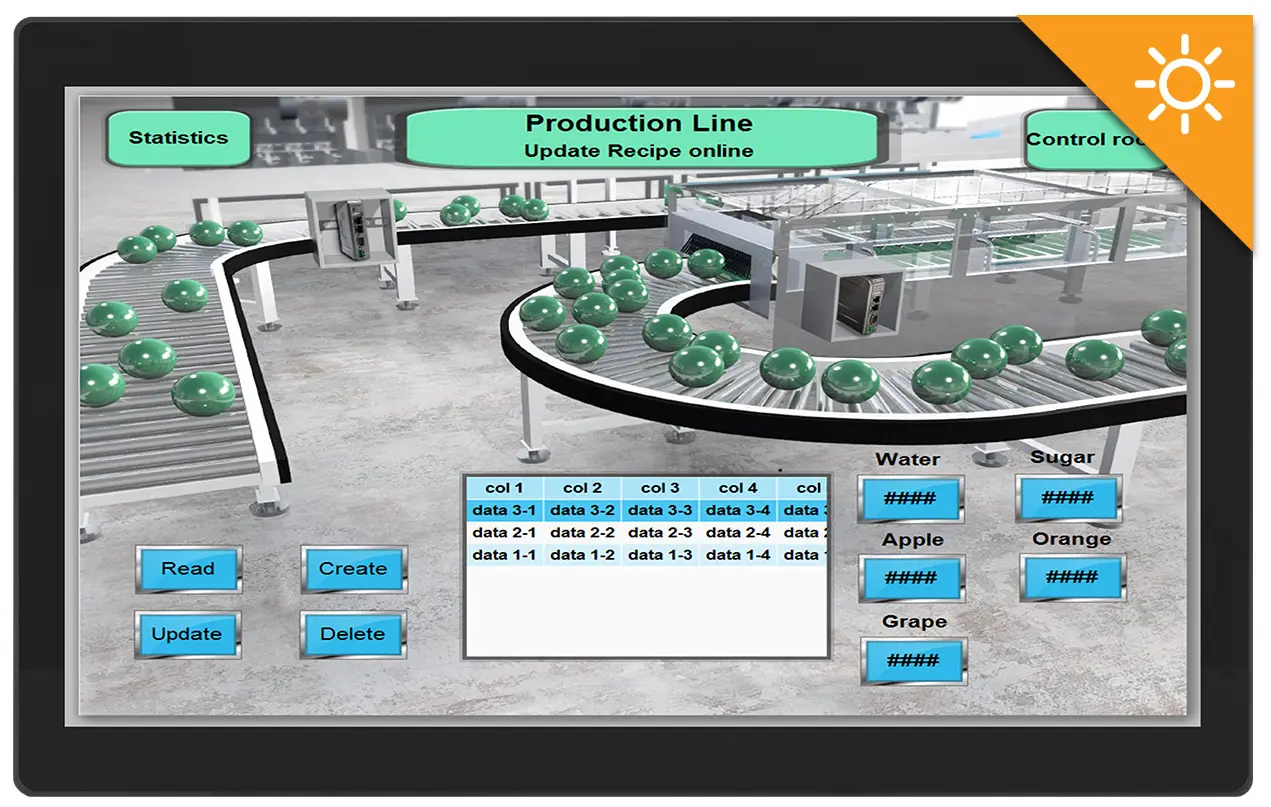

Creating A High-Brightness HMI

Read how one of our customers created a high-brightness HMI by pairing our HDMI-enabled headless HMI with one of our industrial monitors

IPSI chose Maple Systems because of the ease of connecting the HDMI-enabled headless HMI to their legacy control equipment using our free configuration software. The software’s available communication drivers made connections easy to set up, and the built-in data logging and alarm monitoring were easy to configure. IPSI did not need to do any reprogramming of the customer’s existing working drives or PLC controls. Programming and testing could be done offline, allowing them to get the project up and running quickly for their customer, with little downtime for the actual deployment of the Maple Systems components into the system.