HMIs, Edge Gateways, & the IIoT

The Industrial Internet of Things (IIoT) takes data from your factory floor and shares it with a server (local or a cloud service), offering greater efficiency for network use and enabling better access to and better sharing data for your entire organization. This section dives into how you can integrate the IIoT into your business today, and why you should be using Maple products.

.

Overview

.

The Industrial Internet of Things (IIoT) is here and its changing the way manufacturers think about business. These days, everyone wants to be connected, synched up, wireless and remoted in. You name it, we want to be connected to it. Within the manufacturing industry there is a great need and desire for increased connectivity and access to valuable data from our factory machines.

Maple Systems can serve as your guide, making it an easy process to join the next evolution of automated control. Maple Systems HMIs and Gateways are your gateway to the IIoT. Our products are an access point enabling operating equipment on the plant floor to connect to information technologies of the World Wide Web, databases, smart phones, analytic software, and more. Achieve better access to invaluable data and open up a world of possibilities for your business.

What is possible with the IIoT fifty years from now is beyond our current imagination. But this allows us to leverage excellent opportunities that exist today. You can enjoy a connected factory today, reaping great benefits and rewards that will literally touch every corner of your business. And as for the future? We invite you to dream big.

.

.

Features & Benefits of the IIoT

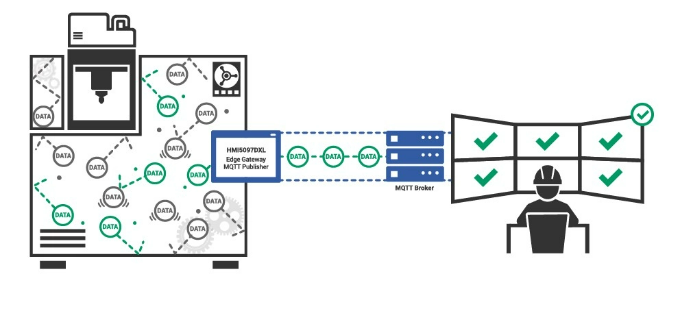

This image represents the beauty of the IIoT. The data is unlocked and optimized so only the data required/requested goes where it is needed. Communication networks are protected from excess traffic and the operator can focus on information critical to their task at hand because unnecessary data clogging the network and distracting the operator is kept out of the system.

- Faster transfer of information

- Automatically receive data updates

- Reduced costs

- Increased amount of open communication

- Easier system set up and management

- Reduced network traffic due to eliminating the back and forth compared to traditional systems.

- A system that is more responsive to change

- Email notifications for alarms and data backups

- Remote access/monitoring/control functionality

- Data logging for more informed operation and decision making

- Enhanced network security thanks to physically separate dual Ethernet ports.

Edge Gateways

.

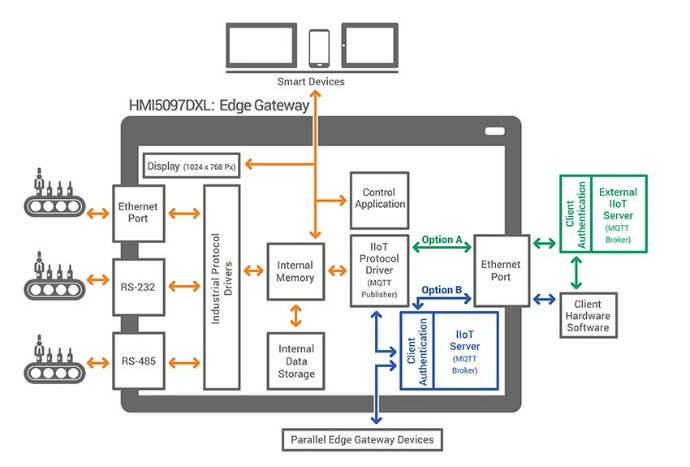

An Edge Gateway unlocks valuable data created by existing operational technology, enabling your business to monetize it further with the power of information technology. In the manufacturing sphere, edge gateway devices translate existing data used by control applications into an IIoT-friendly format, sending that data to the Internet for use by IIoT applications.

For successful deployment, an edge gateway device must fulfill key requirements. It must communicate with a wide range of existing equipment and support emerging IIoT protocols such as MQTT and OPC UA. It must be efficient, reliable, and scalable. It must be easy to configure and put into service. Above all, it must be secure.

With support for over 300+ current and legacy industrial automation protocols, enabling them to communicate with a wide array of PLCs, sensors, and more, our HMIs can convert factory floor data into data into an IIoT-friendly format, which can be transmitted to a local data collection point or the cloud.

A Human Machine Interface (HMI) is a perfect edge gateway. The HMI, the operator's window into the machine in the physical world, can easily be extended to play the same role in the virtual world. The HMI is the place where data is aggregated, filtered, and presented to the operator in an intuitive and digestible way. This same data can easily be presented to users connecting to the HMI through the IIoT.

MQTT

.

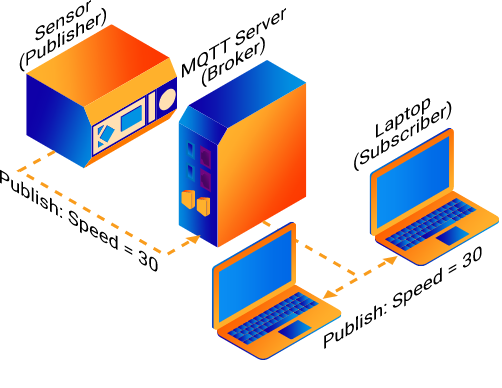

Designed to be light weight, open, and simple, MQTT is a subscriber/publisher messaging transport protocol that is considered a great solution for applications where a small code footprint is required and/or network bandwidth is scarce. It is particularly suitable for continuous monitoring of sensory data such as temperature, pressure, water level, energy monitoring, etc.

OPC UA

.

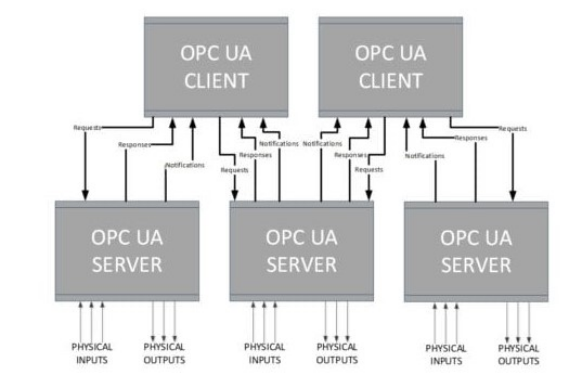

Open Platform Communications (OPC) Unified Architecture (UA) is a communication protocol supported by many SCADA, MES, and ERP software providers. OPC UA uses a Client/Server architecture. This protocol has built-in security with signed and encrypted data transfer using state-of-the-art encryption algorithms. Data is organized into objects, making it easy to access and quickly understand what the data represents, and how to use it.

- Select Maple Systems products come with OPC UA Server functionality built-in, or in most cases, it can be added to non-supported HMIs with a license purchase.

- All of our HMIs can act as an OPC UA Client.

SQL Database

.

Select Maple Systems HMIs can send machine metrics and production data or recipes to an SQL database system directly without any middleware system. That data can then be managed on a larger scale using batch database operations. They also support a built-in database query viewer which enables production machines to retrieve data from your central SQL database.

EBPro Configuration Software

.

With over 300 PLC & Controller communication protocols, our HMIs will easily integrate with your preferred PLC brand Including Allen-Bradley, Siemens, Omron, Emerson, GE, Panasonic, Mitsubishi and all the major protocols is a few clicks away. Creating a powerful edge gateway at a great price has never been easier.

IIoT protocols used to convert factory floor data into an IIoT-friendly format where it can be used company-wide, regardless of the user’s location.

Pick and place objects, pictures, and shapes; create trend display, graphs, XY plots, and pie charts; add passwords and security levels; assign communication (PLC) drivers easily, and more.

EasyAccess 2.0

.

EasyAccess 2.0 is a "cloud service" that allows you to instantly and securely communicate with your Maple Systems HMI from anywhere in the world. Accessibility from outside the plant provides the opportunity to troubleshoot or add new features to the HMI/PLC program by qualified personnel without ever leaving company headquarters.

An administrator grants access to specific HMIs and groups, and traffic is encrypted and secured with VPN. Remote troubleshooting saves money by reducing downtime, travel, and personnel costs. EasyAccess 2.0 integrates perfectly with a wide variety of displays including desktop PCs, laptops, tablets, and smart phones.

Case Study: A Global Network

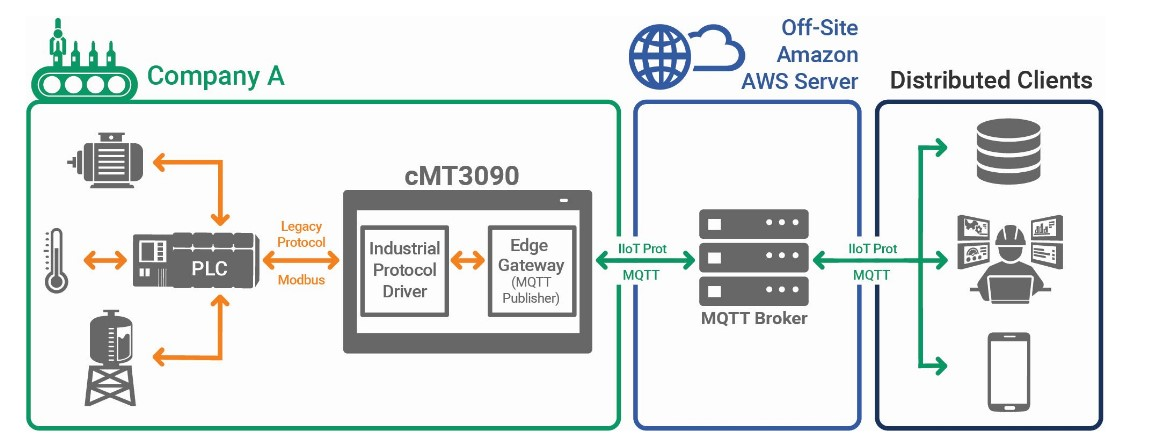

Company A feels the squeeze of market pressures. They need to stand apart from competition and increase profits. With global customers utilizing multiple machines per site, Company A wants to offer customers remote access/monitoring, remote functionality including email alarms, safely enable offsite troubleshooting and configuration, and reduce travel expenses and costly downtime. Company A realizes the IIoT is a great opportunity to differentiate their products.

EasyAccess 2.0 is chosen for secure remote access and its remote troubleshooting capabilities. The MQTT protocol is chosen for its extensive use and documentation with Facebook messenger, established cloud compatibility, and lightweight efficient nature for transporting large amounts of data across wide networks. MQTT also allows Company A to seamlessly expand their existing Amazon Web Services without hogging all available network bandwidth at each manufacturing site.

The company's engineering departments utilize many different PLC brands, all with different protocols. Machines are not able to easily communicate with each other. Thankfully, Maple Systems HMIs have excellent legacy protocol support, enabling data retrieval and conversion from a wide range of existing protocols, serving as a gateway to the IIoT.

Company A finds their solution in cMT3092X 9.7" dual-Ethernet HMI, which serves as both an HMI and edge gateway. The cMT3092X supports the MQTT protocol and over 300 control protocols, enabling the linking of existing control networks with the IIoT. Dual-Ethernet ports offer functionality and security, separating operational technology networks inside the machine from external information technology networks that can be used for an EasyAccess 2.0 connection. This secure connection safely allows for advanced remote functionality such as email alarms, remote access, remote monitoring, and remote programming. As an OEM, dual-Ethernet HMIs allow Company A to maintain an isolated network dedicated to their machinery, yet still offer access to the Internet through their customer's ISP. The publish/subscribe architecture of the MQTT network and EasyAccess 2.0 VPN connection means they won't have to bug their customer's IT departments.

The cMT unit set up is simple and allows them to quickly and easily create control interface projects and take advantage of powerful IIoT features. Because their systems are widely distributed, Company A hosts their MQTT broker offsite with Amazon AWS. Their new data stream is connected to a web application that customers can log into for real-time machine monitoring. EasyAccess 2.0 remote functionality built into the HMI allows Company A to update projects (including offsite MQTT setup) to meet changing customer demands without spending time and money onsite. The company is able to respond faster to software and data demands across their deployed equipment without ever leaving company headquarters. Company A utilizes predictive maintenance instead of preventative maintenance, enabling them to cut costs, improve troubleshooting, and decrease downtime. New machines added to their deployed network send smart data back to the central database for analysis. Sales overall increase because users feel the benefits of more data, accessible to more people.

For future machine builds, Company A will be able to proactively design units by analyzing data from their deployed equipment. Real-time data from deployed cMT3092X units will show how customers actually use their machines as well as highlight popular features used and those to be eliminated. This helps tailor future marketing efforts. Future machines will evolve according to specific data collected on how each feature is used, where the machine shines, and where it struggles.

Case Study: A Single Factory

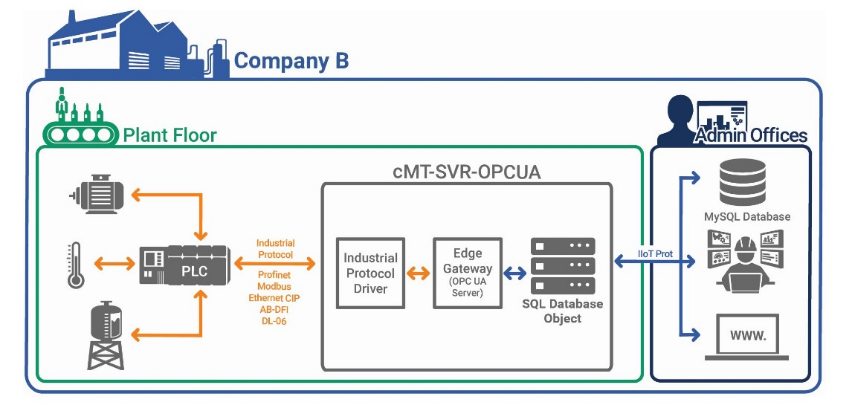

Company B is a single-facility food processing company. Like many in the manufacturing industry their biggest obstacles for IIoT adoption are budget and interoperability. They have an existing SCADA package installation with OPC UA capabilities and a MySQL database.

Company B's factory has both Ethernet and serial control networks unable to share data due to incompatible protocols. The company wishes to centralize data without incurring additional costs for new server equipment and remote hosting. Key requirements for IIoT hardware include support for the OPC UA protocol, legacy protocol support, and secure remote functionality. One of our headless HMIs, the cMT-SVR-100, with a OPC UA license is a perfect fit for Company B's needs since they do not require new displays. This unit is affordable with a small form factor which fits into existing panels.

Company B creates both a project with the necessary communications drivers and an OPC UA Server inside their new cMT-SVR. They define OPC UA tags to bring data from the plant floor into the informational environment, routing that information to dashboards and the SCADA software already in use by management. They also sync data logs to their centralized MySQL server for further analytics. Instead of relying on old data trickling into the system by manual entry, analytic software now offers a live data stream from operating machinery.

Remote access capabilities of the cMT-SVR-100 dramatically change how Company B interacts with their system. The cMT-SVR-100 connects to a laptop/PC or Android/iPad smart device with the free cMT Viewer application, freeing floor managers up to access/monitor machines from the palm of their hand. The email alarm feature alerts staff immediately when something runs amiss, delivering email alerts regardless of location. Dual-Ethernet ports plus serial communication offers a safe connection to office networks exposed to the Internet.

System awareness improves due to centralizing data from all facility machinery. Maintenance costs reduce thanks to linking machine wear data to usage data, improving machine use and extending machine life. By identifying data patterns that indicate likely failures, equipment life is extended, enabling machines to run to full life without risking costly shutdowns. By linking existing control hardware into a single database for access and analysis, Company B increases both the value and profit from data they were already collecting. Streamlined operation, predictive maintenance, and focused growth are achieved. For future machine additions, management will utilize detailed statistics on their highest profit machines and process bottlenecks. The versatile cMT-SVR-100 with a OPC UA license can integrate with any vendor's machine and resource management system, meaning Company B will not be limited to using a single vendor. This will allow future growth targeted toward areas where the greatest impact will be achieved at the lowest cost.

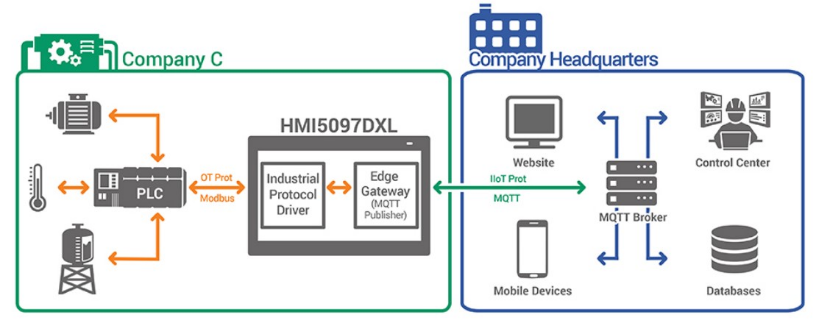

Case Study: System Integrator

Company C is a small local integrator utilizing a Systems as a Service business model. Company C wants to embrace advanced IIoT capabilities to amplify benefits they can offer customers, while reducing internal system maintenance and operational costs. A recent review of a customer site found existing PLCs unable to communicate due to utilizing different proprietary protocols. The existing control system also had no external access due to strict IT department security requirements. In addition to the PLCs, sensors, and actuators required to control onsite equipment, their customer wants a local interface to monitor and control systems. Company C's current maintenance contract with the customer states that Company C must respond to major system faults within 4 hours.

- Support for a wide range of protocols to connect existing controls, new system additions, and future expansions.

- A secure connection to satisfy IT's security concerns and allow remote access

- MQTT protocol to connect to Company C's MQTT broker for system monitoring

- A very low rate of failure since Company C is obligated to cover warranty labor

- An easy configuration environment to facilitate the initial configuration and subsequent system updates and changes

Company C finds their solution in Maple Systems cMT3092X. The 9.7" graphical interface offers visual appeal to grab the operator's attention plus the new features Company C required. Because all Maple HMIs communicate with over 300 different PLCs, there's no need for additional gateways to connect older parts of the system or for future expansions. The cMT3092X's dual-Ethernet ports allow Company C to achieve remote access without compromising control system security. This means most service calls will be solved remotely, saving the expense of onsite visits. And because all Maple Advanced and cMT HMIs support MQTT protocol, Company C can deliver data safely and efficiently directly to their MQTT broker, providing real-time system oversight without spending a fortune to transmit excess data or license SCADA software.

Thanks to using past Maple products, Company C knows they'll receive a reliable product with no warranty issues. Maple's powerful and user-friendly configuration software gives Company C all the tools they need in an intuitive interface. Comprehensive online support and free Maple technical support leave Company C confident they can easily provide customers with the configuration, maintenance, and support they require.

Company C leverages modern IIoT control architecture to expand system oversight and maintenance offerings. Maintaining their own MQTT broker within their existing servers gives Company C access to data needed to monitor customer systems without incurring offsite storage costs. By collecting information from many similar control systems, Company C gains a significant systems awareness advantage. Company C even achieves higher-than-promised energy reductions thanks to tracking and analyzing multiple user data. When local operators implement system usage changes, pertinent data streams directly into the local MQTT server at Company C headquarters. The changes track for short-term impact, long-term output, and system maintenance. Data collected from the system also helps Company C anticipate problems before they arise, limiting expensive off-hour warranty calls. By implementing operational changes supported by factual data, Company C becomes an invaluable partner to their customer's bottom line.

Supervisory Control and Data Acquisition (SCADA)

Connect the Hardware using a Protocol you Know

Maple Systems offers all the components you need to create your own unique level of supervisory data acquisition and control, from the simplest stand-alone machine to sophisticated multi-device networked production line(s), all the way to enterprise-level operations and IIoT functionalities leveraging cloud connectivity. Log data from your devices to aid in reporting, to gain efficiencies, reduce downtime, and plan for routine maintenance. Add additional IIoT functionality like MQTT, OPC UA, Ignition, SQL database integration, and more. Our products can help you standardize communications between devices, gluing different systems together for one source to your SCADA. No need to redesign your entire application. Keep the components that are already working for you, just add Maple Systems components to grow your abilities to supervise, control, and acquire data.

Log data from your devices to aid in reporting, to gain efficiencies, reduce downtime, and plan for routine maintenance. Add additional IIoT functionality like MQTT, OPC UA, Ignition, SQL database integration, and more. Our products can help you standardize communications between devices, gluing different systems together for one source to your SCADA. No need to redesign your entire application.

Keep the components that are already working for you, just add Maple Systems components to grow your abilities to supervise, control, and acquire data.

To learn more about how our products work together to create scalable SCADA solutions, visit our SCADA solutions page .