The Edge Gateway

How can your bottom line benefit from the Industrial Internet of Things today and in the future? Enter the Edge Gateway. The edge gateway unlocks valuable data created by existing operational technology, enabling your business to monetize it further with the power of information technology. In the manufacturing sphere, edge gateway devices translate existing data used by control applications into an IIoT-friendly format, sending that data to the Internet for use by IIoT applications.

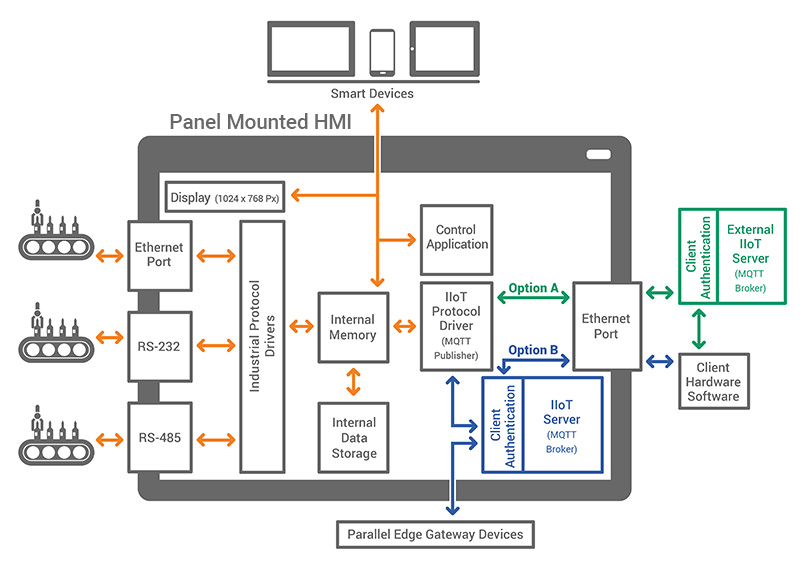

For successful deployment, an edge gateway device must fulfill key requirements. It must communicate with a wide range of existing equipment and support emerging IIoT protocols such as MQTT and OPC UA. It must be efficient, reliable, and scalable. It must be easy to configure and put into service. Above all, it must be secure.

With support for over 300+ current and legacy industrial automation protocols, enabling them to communicate with a wide array of PLCs, sensors, and more, our Advanced and cMT HMIs can convert factory floor data into data into an IIoT-friendly format, which can be transmitted to a local data collection point or the cloud.

Maple Systems HMI—Your Edge of Network Gateway

A Human Machine Interface (HMI) is the perfect device for this role. The HMI, the operator's window into the machine in the physical world, can easily be extended to play the same role in the virtual world. The HMI is the place where data is aggregated, filtered, and presented to the operator in an intuitive and digestible way. This same data can easily be presented to users connecting to the HMI through the IIoT.

Works Well with Other Products and Systems

A primary requirement of the IIoT is the ability to work easily and flawlessly with other products and systems. The dizzying array of communication protocols used in manufacturing today could present a significant problem here. Fortunately, Maple Systems HMIs come with extensive libraries of industrial protocol drivers operating on different network architectures. Working seamlessly with other products and systems, Maple HMIs have the ability to unlock valuable data from existing machinery regardless of the protocol used. For example, Maple Systems HMI5097DXL has three serial ports, a CANbus port, and dual-Ethernet, which can operate simultaneously utilizing over 300 different protocols. The dual-Ethernet ports allow dedication of one port for real-time industrial control network demands while the other is reserved for external network connections and IIoT functionality. Distinctly separate Ethernet ports offer added security, since a direct network path does not exist to the machinery itself.

Increased Communication

MQTT is one of many internet-enabled features available on Advanced HMI and cMT edge gateway devices, offering increased communication and data collection. For example, HMIs can send emails containing data log and alarm conditions. Remote access applications allow remote users to monitor and control machines through secure VPN connections and enables remote download of project updates. Database integration allows machines to log data directly to database servers over a LAN. Custom server/client applications enable smart device integration (Android/Apple tablets) for machine monitoring and control, moving the touchscreen out of the panel and into the operator's hands. Compared to machine replacement, edge gateway-enabled HMIs are an inexpensive option for upgrading existing machines or adding to new machine builds.

Safety Comes First

With so many features and access options, edge gateway safety and security are of utmost concern. This is why the Maple Systems HMIs can restrict access to data streams to authorized personnel and devices. There will always be a need for on-site trained control personnel ready to react to unsafe conditions. For critical systems that require onsite personnel for safety, the added protection of a one way, read-only connection allows offsite monitoring without control. This enables companies to meet their IIoT needs without sacrificing safety and security. The HMI edge gateway maintains the vital role of local machine control while opening up new possibilities in the IIoT today, tomorrow, and beyond.