Related Links

Software

Manuals & Guides

- EBPro Quick Start Guide

- EBPro Programming Manual

- cMT Quick Start Guide

- cMT-SVR Installation Manual

- OPC-UA Set-up Overview

- MQTT User Manual

- EasyAccess 2.0 Manual

- cMT Microsoft® SQL Quick Start Guide

- cMT MySQL Quick Start Guide

Tech Notes

Videos

- Product Overview

- Quick Start: Part 1 - Introduction and Installation

- Quick Start: Part 2 - Create a Project

- Quick Start: Part 3 - Creating Windows

- Quick Start: Part 4 - Creating Static Elements

- Quick Start: Part 5 - Creating Digital Objects

- Quick Start: Part 6 - Create and Group Analog Objects

- Quick Start: Part 7 - Simulation Mode

- EasyAccess 2.0 Overview

- Assign a New HMI to Your EasyAccess 2.0 Domain

- Smart HMI Introduction

Sample Projects

- cMT Microsoft® SQL Database Server

- cMT MySQL Database Server

- MQTT Set-up

- Operation Log

- Quick Start Guide Project Files

Controller Information Sheets

See Our List of

Controller Information Sheets

Communication Cable

See Our List of

Communication Cables

⇐ Back to IIoT Solutions

HMIs Double as Edge-of-Network Gateways

Enter the edge gateway. The edge gateway unlocks valuable data created by existing assets. In the manufacturing sphere, edge gateway devices translate data used by control applications into an IIoT-friendly format, sending that data to the Internet for use by IIoT applications.

An edge gateway device must fulfill key requirements. It must be efficient, reliable and scalable. It must also be easy to configure and put into service. Above all, it must be secure. And it must communicate with a wide range of existing equipment and support emerging IIoT protocols such as MQTT (formerly MQ Telemetry Transport). This is an ISO standard (ISO/IEC PRF 20922) publish-subscribe-based “lightweight” messaging protocol for use on top of the TCP/IP protocol. It is designed for connections with remote locations requiring a small code footprint or a limited network bandwidth.

An HMI is a good candidate for serving as the edge gateway device. The HMI, the operator’s window into the machine, can easily be extended to play the same role in the virtual world. The HMI is the place where data is aggregated, filtered and presented to the operator. This same data can easily be presented to users connecting to the HMI through the IIoT.

A primary requirement of the IIoT is interoperability. The dizzying array of communication protocols used in manufacturing today present a significant barrier. Fortunately, modern HMIs possess extensive libraries of industrial protocol drivers operating on different network architectures. This makes Maple Systems HMIs the perfect means of handling the interoperability challenge.

Data transmitted by the edge gateway-enabled HMI must be presented to upstream IT applications in a way that is flexible, modular and efficient. The MQTT feature available on Maple Systems HMIs exemplifies the power of this protocol. MQTT is organized into topics that can contain single data points or a group of related data points. The HMI can be configured to publish data to a specific topic whenever a change arises, or periodically, lowering the bandwidth needed for data transmission.

A fundamental advantage of MQTT is that data goes to a central “broker” instead of directly transmitting to multiple clients such as remote interfaces or management software. The MQTT broker is responsible for maintaining client connections and sending/receiving messages. Client devices, edge gateways and IT applications (or publishers/subscribers in MQTT language) are freed up to focus on producing and consuming data. This division of labor greatly enhances scalability. As the overall system size grows, the CPU resources and bandwidth requirements of the edge gateway remain static.

In addition, MQTT is a lightweight protocol. Common broker implementations consume only about 3 MB of RAM with 1,000 connected clients. This small footprint means the HMI can be configured as both an edge gateway and as an MQTT broker, reducing the need for additional hardware.

Applications engineers have a lot of flexibility using the data an edge gateway produces as an MQTT publisher. Engineers can assign topic names to the variables or tags they wish to publish to the broker. Topics provide the structure for organizing data in the MQTT protocol. MQTT allows topics to be divided in intuitive ways. A single data point can be assigned to multiple topics, and one topic can contain more than one data point. An application can subscribe to all topics from a single HMI, creating an application monitoring all data from one specific machine. Or, if a parameter (say temperature) exists on many machines, the programmer can use a topic “wild card” to instantly subscribe to the same parameter across all machines. This enables efficient and easy detection of abnormal conditions across an entire installed base of machines.

The HMI configuration process is easy for the controls engineer who incorporates an edge gateway into a system. The engineer simply creates an authenticated broker connection, then selects the tags to publish. The engineer organizes tags into topics, then downloads the project to the HMI.

MQTT is one of many Internet-enabled applications available on edge gateway devices, such as Maple HMIs, which offer many notable communication and data collection features. HMIs can send emails containing data logs and alarm conditions. Remote access applications let remote users monitor and control machines through secure VPN connections. They also enable remote download of project updates. Database integration allows machines to log data directly to database servers over an Internet connection (LANWAN). The cMT Viewer and HMI Viewer applications enable Android and Apple tablets and smartphones to monitor and control your HMI. Compared to a full machine replacement, our edge gateway-enabled HMIs are an inexpensive option for upgrading machines or adding to new machine builds.

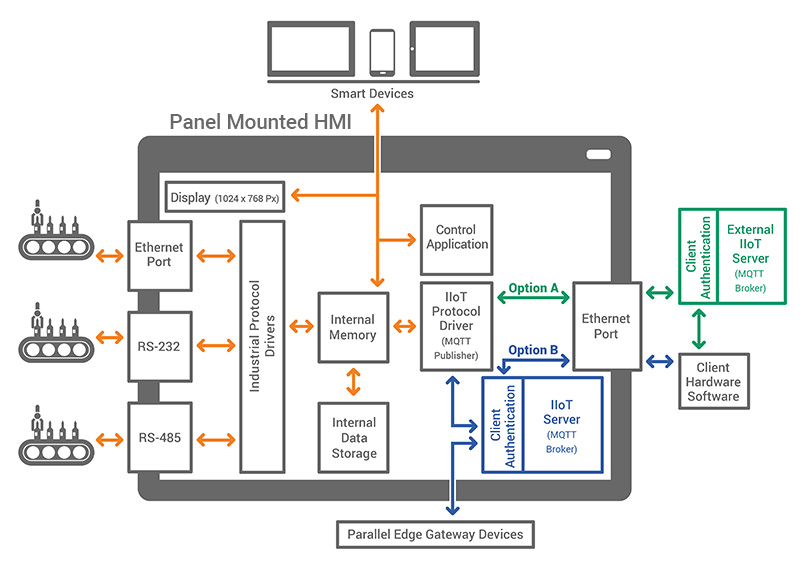

Here’s an example of how the configuration process typically works. Company A wants to offer customers remote access/monitoring, remote email alarms, off-site troubleshooting and configuration, and similar benefits. Company A goes with the MQTT protocol for its extensive use, excellent documentation, cloud compatibility, and ability to efficiently transport large amounts of data across networks. MQTT also allows Company A to seamlessly expand its Amazon Web Services functionality without hogging all available network bandwidth at each manufacturing site.

The company’s engineering departments use many different PLC brands, all with different protocols. So, Company A decides to use a Maple Systems Dual-Ethernet HMI, which serves as both an HMI and edge gateway. The HMI supports MQTT and more than 350 other control protocols, letting it link existing control networks with the IIoT.

Dual-Ethernet ports separate networks inside the plant from external information technology networks. This secure connection allows for advanced remote access and monitoring, remote email alarms and remote programming. Dual-Ethernet HMIs let Company A maintain an isolated network dedicated to its machinery, yet still offer access to the internet through the customer’s ISP. The publish/subscribe architecture of the MQTT network means Company A personnel won’t have to issue any change requests to their customers’ IT departments.

Because their systems are widely distributed, Company A hosts its MQTT broker off-site. The new data stream connects to a web application that customers can log into for real-time machine monitoring.

Remote functions built into the HMI allow Company A to update projects (including performing off-site MQTT setup) to meet changing customer demands without spending time and money on-site. It can respond faster to software and data demands across deployed equipment. Company A uses predictive maintenance instead of preventative maintenance to cut costs, improve troubleshooting and reduce downtime. New machines added to the network send smart data back to the central database for analysis.

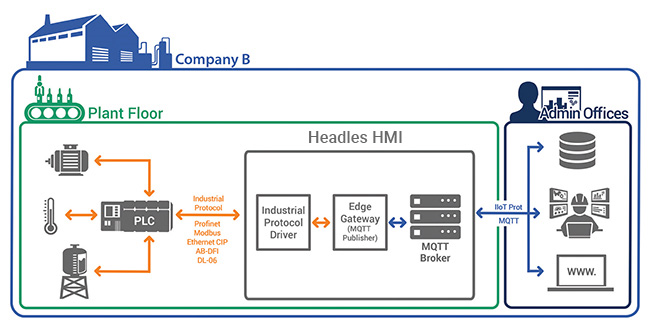

Consider another example involving a single-facility food processing company. Like many in the manufacturing industry, Company B’s biggest obstacles for IIoT adoption are budget and interoperability. Its factory hosts both Ethernet and serial control networks unable to share data because of incompatible protocols. The company wants to centralize data without buying a new server and remote hosting. Key requirements for IIoT hardware include support for the MQTT protocol, legacy protocol support and secure remote access. A Maple Systems Headless HMI fits Company B’s needs because there’s no requirement for new displays. This unit has a small form factor that fits into existing panels.

Company B creates both a project and the MQTT broker inside its new interfaces using EBPro configuration software. They define MQTT topics to bring data from the plant floor to dashboards and analytics programs in use by management. Analytics software can now offer a live data stream from operating machinery.

Remote access for the Headless HMI securely connects over a VPN to laptops, Android and Apple smartphones or tablets, giving floor managers mobile access. The email alarm feature alerts staff immediately when something runs amiss regardless of location. Dual-Ethernet ports plus serial communication offers a safe connection to office networks exposed to the Internet.

The centralization of data from facility machinery boosts overall system awareness. Maintenance costs drop thanks to the linking of data about machine wear and usage. Software identifies data patterns that indicate likely failures, so machines can run to full life without risking costly shutdowns.

All in all, Company B can derive new insights using detailed statistics on both its highest-profit machines and on its process bottlenecks. The Maple Systems HMI edge gateway performs local machine control while opening these new possibilities in the IIoT.

⇐ Back To IIoT Solutions

Please Sign in or Register to continue reading this article.