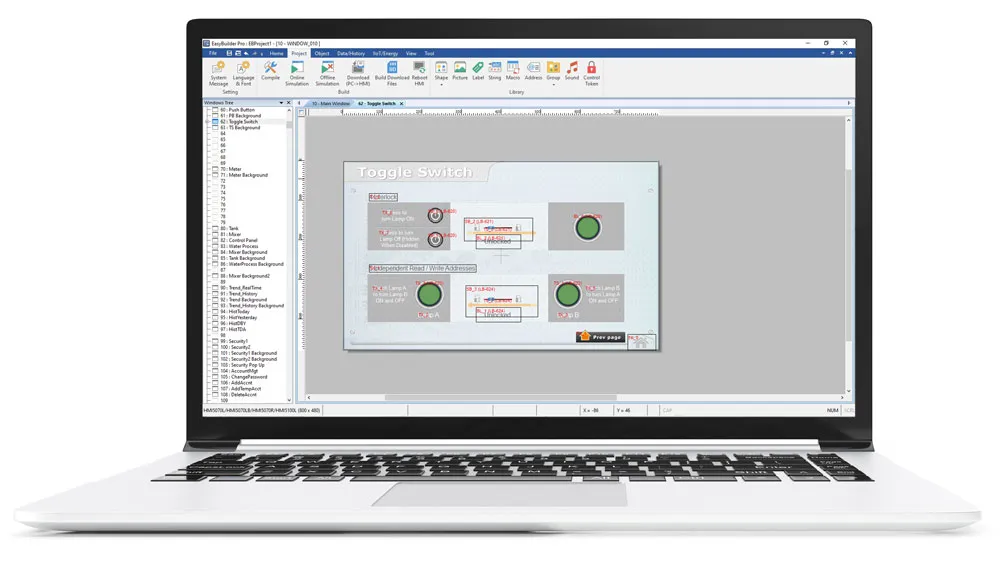

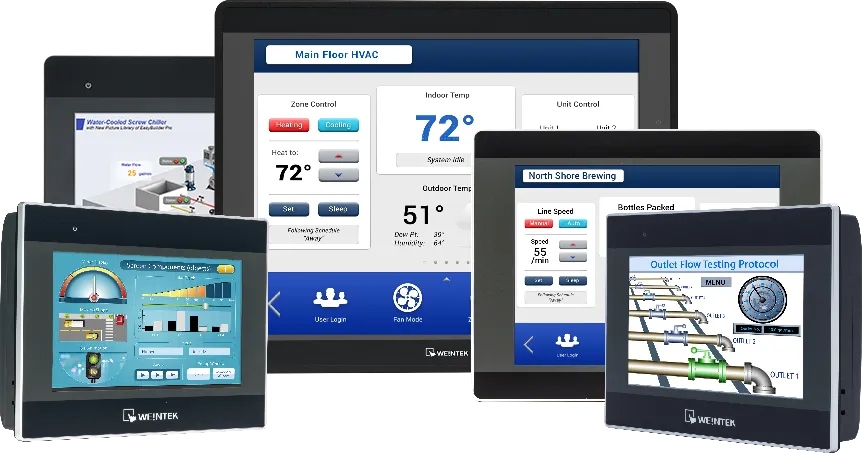

The HMI view of an operator interface terminal, whether on a local

display, mobile tablet, supervisory panel PC, or remote workstation, is

only one view of the important data in an automation system. There are

also; alarm and data logging, database integration, recipe management,

protocol translation and more. cMT Series Products prove to be a

flexible tool in these areas as well. Let's tour a few features

available to manage your data on the cMT products:

Modbus

Gateway

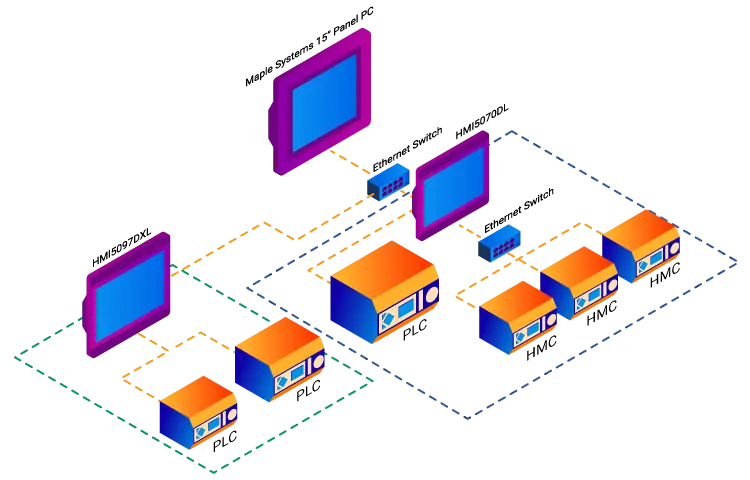

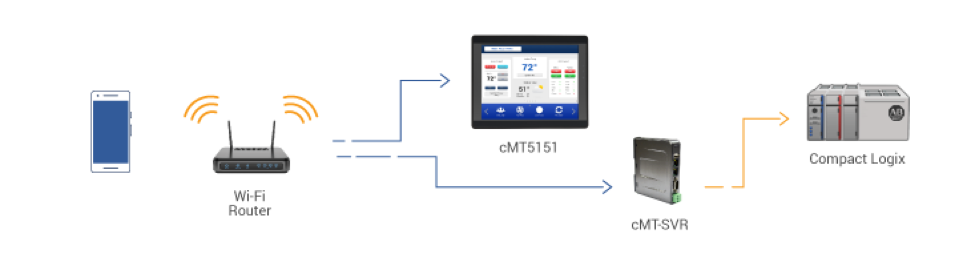

In an ideal world, every machine vendor and systems integrator would use

the same protocol and all equipment would seamlessly communicate with

everything else on a plant floor. More often than not, this is far from

the case. As a plant grows over time and different systems are added,

little thought is given to the process as a whole. You'll often find

different systems, from different manufacturers, speaking different

protocols, on different serial busses. Fortunately, cMT products speak

many languages. cMT Series Products can use over 300 protocols on any of

the available com ports, and translate them to the default industrial

standard protocol: Modbus TCP/IP. The cMT device becomes a transparent

protocol translator, allowing upstream SCADA systems to connect to PLCs

as if they were all using the same protocol on the same

bus.

Modbus Communication

Gateway

Database

Object

Database

Object

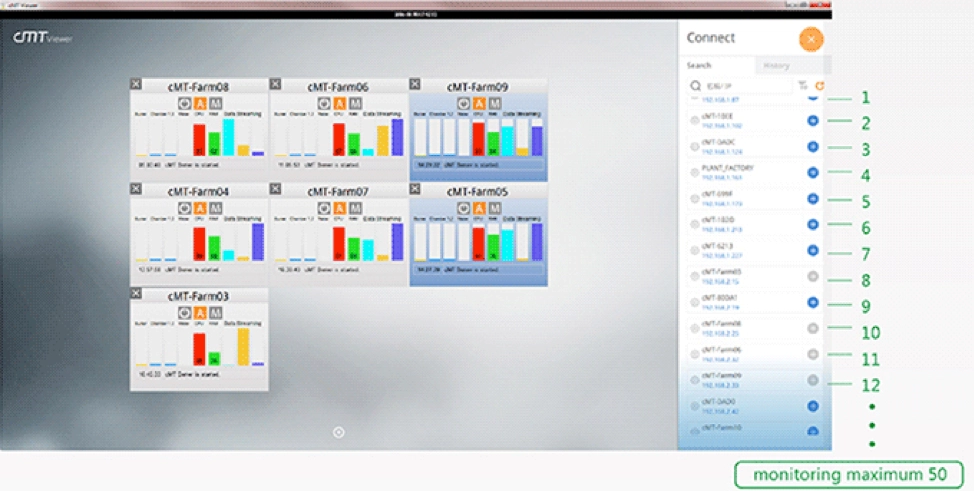

Increasingly, data that machines produce needs to be recorded and

preserved. The data may be useful in process improvement or may be

required by regulatory agencies. The cMT products have an object which

allows them to log a data sampling object or an alarm log directly to an

SQL database server over an Ethernet LAN.

This eliminates the need for manually retrieving and entering log files

from each machine independently. Data from many different sources can be

aggregated and stored in one central safe and secure location,

automatically.

Databases and

Recipes

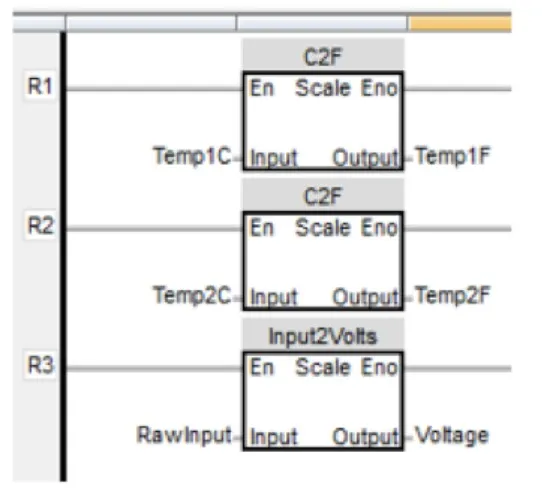

Recipes are a collection of parameters stored in the HMI that can be

transferred to a machine with one press of a button. Different parts may

require different amounts of material, different cook times and

temperatures, or different processing steps. This data often needs to be

shared across multiple machines that may be at different steps in the

process, or may be redundant production lines working on producing the

same or similar products.

SQL databases can act as a storage tank for all machines sharing a

particular recipe database. cMT HMIs can query the database for current

recipe data before sending those parameters to the PLC. This way,

changes only need to be made to this central database, instead of

manually changed in each HMI.

This feature saves time in systems that have many machines sharing many

recipes. The changes, additions, and deletions to the database only need

to be made in one place and are then automatically updated throughout

the system. This ensures production uniformity throughout the system. A

single machine will not get stuck using an outdated recipe simply

because someone forgot to update it.

New technologies bring new ways of interacting and controlling systems,

but the need for a static HMI that is always ready and available will

not go away. While cMT Series HMIs enable new and exciting features, the

cMT Series also does not compromise on fulfilling this vital role.

New technologies bring new ways of interacting and controlling systems,

but the need for a static HMI that is always ready and available will

not go away. While cMT Series HMIs enable new and exciting features, the

cMT Series also does not compromise on fulfilling this vital role.