HMI+PLC Configuration Software Features

Our HMC series combines a touchscreen HMI and PLC all in one unit. Utilized worldwide to employ diverse applications, our HMI+PLCs lower costs, save space, and feature options including: Serial and Ethernet communication, support for Class I Division 2 installations, and numerous I/O configurations. What's more, they provide an affordable combination of display and control in a single package and programmed by using our Free MAPware7000 software with graphs, alarms, trending, data logging, web server functionality and more.

Advanced models unlock additional functionality such as MQTT, VNC Server, email, advanced graphics, recipe database, and much more.

| Software Features | |||||

|---|---|---|---|---|---|

|

Alarms

Display an alarm message on screen to notify the operator when a

parameter or process goes out of bounds.

Alarm Basics

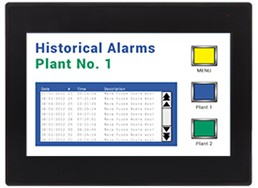

Real-Time Alarms

Real-time alarms are programmed to trigger when certain events in

your process occur. Alarms display in real-time to show the current

status of a process. When real-time alarms are triggered, they

remain on the display window until they are acknowledged. The alarm

condition then returns to its normal state. Display real-time alarms with different text colors to delineate the state of the alarm (active unacknowledged, active acknowledged, or inactive unacknowledged), severity, date and time, etc. Historical Alarms

Historical alarms are a sequential history of your application's

alarm activity. Stored in non-volatile memory, they remain even when

the machine is turned off. Historical alarms can be displayed with

the severity level, date, and time the alarm occurred, when it was

acknowledged, and when it returned to normal. A historical alarm

list can also be uploaded to the PC and saved as a CSV file using

MAPware-7000.

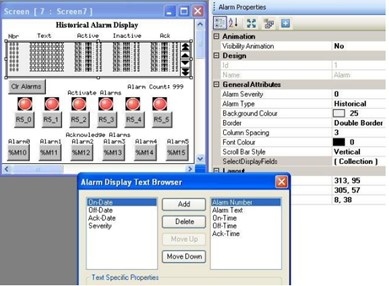

Alarm Configuration

Configure alarm Windows® with scroll bars

(left/right/up/down) to view long or wide alarm lists. Export the

alarm data in MAPware-7000 as a CSV file for editing, then import it

back into MAPware-7000.

Severity Categorization

Alarms can be categorized and filtered by severity by assigning one

of nine severity levels to each alarm. Then choose which alarm

numbers you wish to view. For example, easily view alarms with a

severity level of six or higher, etc.

Additional Useful Features

For more information on Alarms, refer to the MAPware-7000 Programming Manual or watch one

of our Training Videos:

Local Alarms in IEC Mode External Alarms in IEC Mode. How to Program Alarms See the Documentations and Resources tab for more information on our training videos, sample projects, manuals, and tech notes. |

|||||

|

Application Conversion and Import/Export

Options

MAPware-7000 provides a method for converting a project created for one

model into a project for a different model.

Application Conversion

Convert a project from one model and screen size to another

using the Convert Application tool. This allows you to take a

MAPware-7000 project developed for one model and use it on a

different model without having to recreate the project all over

again.

Import/Export Tags

Tags can be exported from a project to the CSV file format and

edited in Excel before importing them back into the project, or

into another project. This saves time and allows for flexibility

during project design.

Import Screens

Screens and their associated tags can be imported from another

project into your current project to speed the development

process. See our Support Center for our the MAPware-7000 Programming Manual, Getting Started Guides, Module Guides, Logic Guides, and training Videos all designed to help you get your project started. |

|||||

|

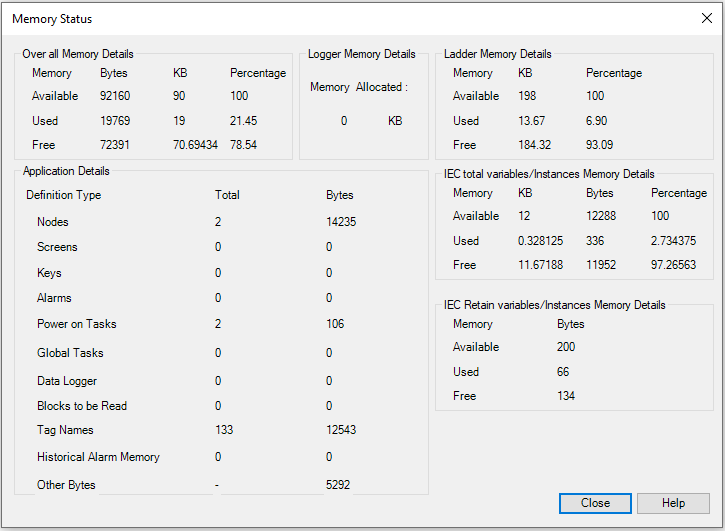

Application Memory Status

The Application Memory Status feature is a tool available in the

MAPware-7000 software that is used to display memory used by the current

project. This tool can be used to determine how much memory is still

available for new screens, ladder logic, etc.:

Memory Status Box

MAPware-7000 tracks the memory requirements of your project and

displays the following information in the Memory Status box:

Screens and their associated tags can be imported from another

project into your current project to speed the development

process.

Keep Memory Area and

Retentive Tags

See our Support Center for our the MAPware-7000 Programming Manual, Getting Started Guides, Module Guides, Logic Guides, and training Videos all designed to help you get your project started. |

|||||

|

Barcode Scanner

A Barcode Scanner display object can be placed on

screen that will display a string value sent to a register by a barcode

scanner connected to the HMC over USB.

|

|||||

| Custom Start Screen In MAPware V2.36 and newer, a custom boot up screen (HMC4000) or message (HMC2000, HMC3000) can be configured to display after the HMC has powered on and before the project has loaded. If no custom boot up screen is configured, the default "Maple Systems" boot up screen will display. | |||||

|

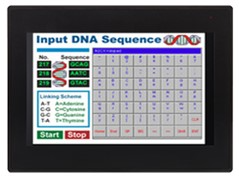

Data Entry

The Data Entry feature offers you a variety of methods to edit data in

the PLC.

Inputting Data

Alphanumeric ASCII Keypad

Numeric Input Keypad

For more information on Keypads, refer to the MAPware-7000 Programming Manual.

|

|||||

|

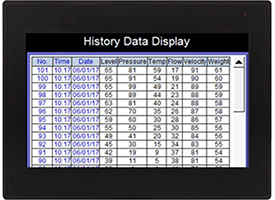

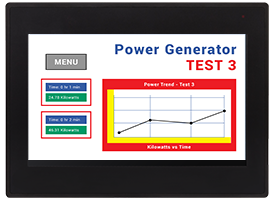

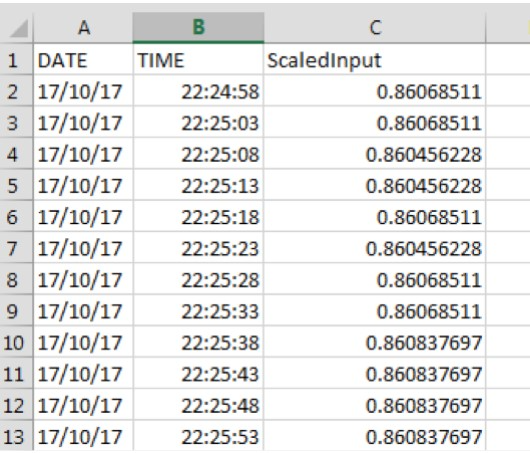

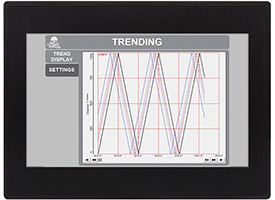

Data Logging and Trend Graphs

Data Logging

The Data Logger available in the HMC3000 series is used

to record values of tags over time. Data is collected and stored in

the

HMI + PLC's non-volatile memory or attached SD card and can be

displayed on the

HMI + PLC screen using the Historical Trend or Real Time Trend

objects. The

Data Logging feature is most often used for data acquisition where

the HMI + PLC

gathers and saves important process information for analysis.

Trend Graphs

Use real-time trend and historical trend objects

to capture and graph data over a period of time:

Use real-time trend and historical trend objects

to capture and graph data over a period of time:

Viewing Data

Collected data can be viewed several

ways:

Printing Data

Data Logger records can be sent to a serial

printer connected to the HMI + PLC.

|

|||||

|

The Data Monitor feature is a window available in the MAPware-7000

software that displays data values in unit's internal memory. The entire

internal memory of the unit is accessible using the Data Monitor but you

select what areas of memory you wish to monitor. In addition to reading

values, you can modify data online or create a table of preset values to

download to the registers. With this feature, you can quickly view data

in table format or to initialize areas of memory in the unit. In

addition to reading values, you can modify data online or create a table

of preset values to download to the registers. For more information on the Data Monitor feature, refer to the MAPware-7000 Programming Manual. |

|||||

|

Data Window

This handy feature is similar to a Watch window. It allows you to

construct a table of memory addresses that can be monitored from the

MAPware-7000 software while your PC is connected 'online' to a Maple

PLC.

Data Window

The Data Window provides an easy tool that can be used to debug

your project. In addition, the Data Window can also be used to

download preset values to the PLC for testing.

Additionally, the Data Window allows you to:

For more information on the Data Window feature, refer to the MAPware-7000 Programming Manual.

|

|||||

|

Debug Mode

The Debug feature provides various functions that can be helpful when

troubleshooting the ladder logic in your unit. A debugger allows users

to slow down the execution of a ladder logic sequence to a human time

scale so that they can see what the unit is doing one ladder instruction

at a time. This is the best way to understand what the unit is doing

while it is occurring. The Debugger allows the user to set breakpoints

to halt execution at a particular point in the logic and then step

through, one instruction at a time, watching the data fields update at

each and every step. To use the Debug options, you must be online. Up to eight breakpoints can be set to pause logic operation at different points. The watch window can be used to monitor tags while debugging, and variable can be added or removed during runtime.

Supported debugging commands:

For more information on the Debug feature, refer to the MAPware-7000 Programming Manual.

|

|||||

|

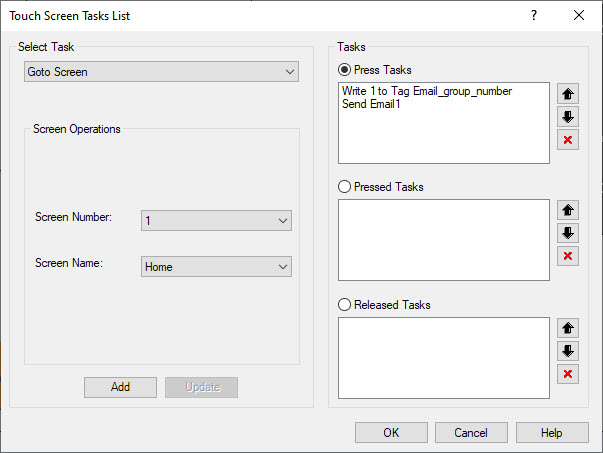

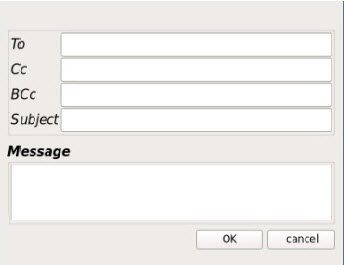

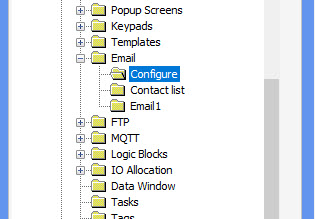

Email

The HMC4000 Series models can be configured to send an email when an

alarm triggers or at the press of a button.

Email Alarm Notifications

A critical process at a remote location requires attention. The HMC4000 can send an email to key personnel to let them know of the situation. A screenshot of an HMI window showing relevant data can be attached to the email or embedded if desired. Configure individual alarms to send an email to a specified group of recipients when the alarm is triggered. Create different groups (up to 16 groups) with various combinations of recipients for each group. Send Email with a Task

Use an Advanced Multitask Button to send an email. In the button properties, select Tasks and select "Send Email" from the dropdown menu. Specify the email screen numberm the screen name and the contact group to which the email will be sent.

An email can be sent to a recipient specified at runtime using the Email on Fly task, which can be found in the task list for a Multitask Button. When this button is pressed on the HMI screen, a window will pop up that has entries for the recipient email(s), subject and message.

Configure Email

Configure the Email Settings by expanding the Email folder in the Project Information Window in MAPware-7000 (HMC4000 projects only).

|

|||||

|

Fonts and Languages True Type Fonts

Display text and labels with True Type fonts available on the

Windows® operating

system.

Multi-Language Feature

The multi-Language feature enables the programmer to configure the

project for use in many countries around the world that may use a

different language. You can configure each object or text box with

multiple labels, each designed for a unique language. During

operation of the unit, display a screen that allows the operator to

select which language he/she prefers to use. Once selected, all the

objects and text boxes immediately depict the appropriate label.

The Import Text Objects and Export

Text Objects

The Import Text Objects and Export Text Objects features allow you to

export a listing of all objects that can display Multilingual (Windows

fonts) text. This is particularly handy when using the Multiple Language

feature. Instead of entering each language object-by-object in

MAPware-7000, you can export to a CSV (comma-separated value) file, and

then edit the file using another application such as Microsoft Excel.

For more information on Fonts & Languages, refer to the MAPware-7000 Programming Manual or watch our video Multiple Languages. |

|||||

|

FTP Server

To use the FTP feature there must be an FTP server accessible at the

configured IP address. The FTP server must be configured with the user

and password specified and must permit write access for that user. The

SD card must be present and contain a log file to send.

Provided the above conditions are met, the unit will periodically upload a *.csv file to the FTP server. A new file is created each time the unit transmits data logger data to the FTP server. Each file will contain only the data recorded since the last file was sent. The name of each *.csv file consists of the file name specified for the group number, appended with the date and time information for when the file was sent. The period contained in each log file is determined by the Send File at Every field in the FTP Client Configuration window.

Logs are kept on the SD card that detail what data has been sent to

the FTP server. Data

transmission can be turned on or off with a button press. To use the

FTP feature, there must

be an FTP server accessible at the configured IP address. The FTP

server must be configured

with the user and password specified and must permit write access

for that user. The SD card

must be present in the HMC and contain a log file to send.

The MLC2 PLC model has an additional option when using the Data Logger feature described above. Data collected from the Data Logger can be transferred to a *.CSV file, then immediately sent to an FTP Server via the Ethernet port or one of the serial ports. For more information on the FTP Server, refer to the MAPware-7000 Programming Manual |

|||||

|

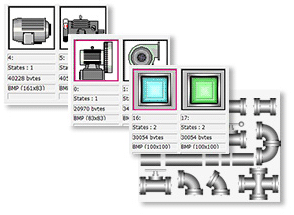

Functional Graphics

MAPware-7000 includes a large assortment

of functional graphic images to reflect the look and feel of

your operation. Use colored graphic images to indicate the

status of a process, the state of a device, or any action

you would like represented. Images are used to represent

objects including:

For the HMC4000 series, visible objects support color gradients. |

|||||

|

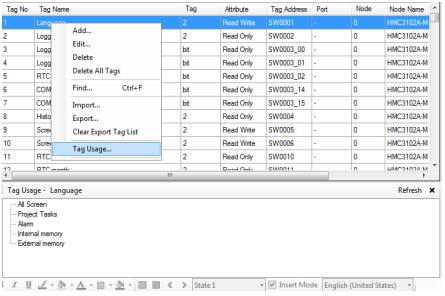

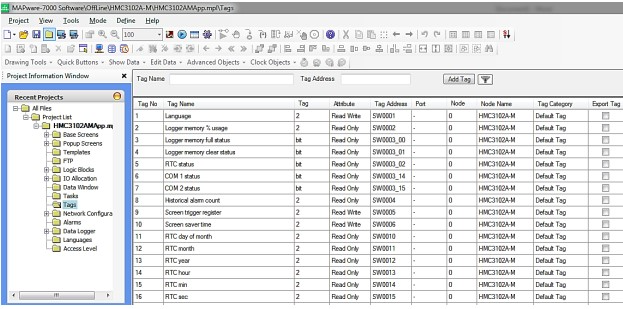

Importing and Exporting Tags

The tag database created in MAPware-7000 exports as a CSV

(comma-separated value) file. You can edit this file then import back

into MAPware-7000. This provides the following advantages:

Tag Usage

This feature allows you to select a tag in the tag database and

view where it is used in your project:

To read more about creating, adding, finding, editing, or

deleting a tag in the MAPware-7000 Programming Manual. Or

watch our video, Screens and Tags Creation.

|

|||||

|

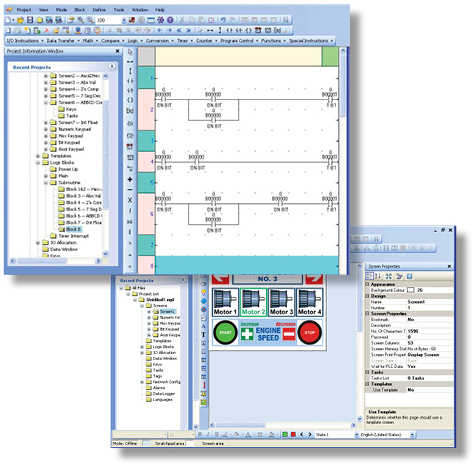

Logic Blocks

Use ladder logic or IEC61131-3 programming to create the logic for

monitoring and controlling your system.

An important aspect of MAPware-7000 is

the ability to separate your PLC application into logic

blocks. Logic blocks help to keep your project organized and

easier to code. Up to 256 logic blocks can be created. In

MAPware-7000, there are five types of logic blocks:

|

|||||

|

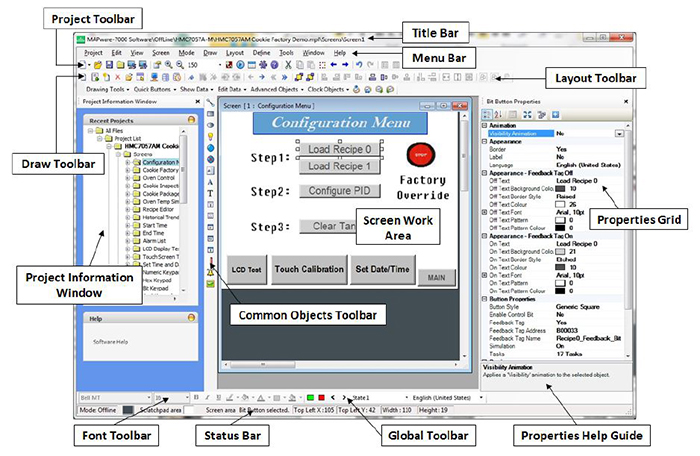

Main Screen

The main screen in MAPware-7000 is divided into logical sections

providing access to many tools needed to create a unique graphic

display including: menus and toolbars, project information, screens

and logic block work area, and individual properties for selected

objects.

The MAPware-7000 configuration software provides access to many

basic tools

necessary to create a graphic representation of your control system.

Display

data in various formats, modify data, and create the underlying

logic to

monitor variables in the control system and respond accordingly. The

main

screen in MAPware-7000 is divided into logical sections providing

access to

many tools needed to create a unique graphic display including:

menus and

toolbars, project information, screens and logic block work area,

and

individual properties for selected objects.

The MAPware-7000 configuration software provides access to many

basic tools

necessary to create a graphic representation of your control system.

Display

data in various formats, modify data, and create the underlying

logic to

monitor variables in the control system and respond accordingly. The

main

screen in MAPware-7000 is divided into logical sections providing

access to

many tools needed to create a unique graphic display including:

menus and

toolbars, project information, screens and logic block work area,

and

individual properties for selected objects.The graphic shown displays main elements of the MAPware-7000 software screen: Menus and Toolbars

The upper section of the main screen contains the menus and

toolbars. The menus

and toolbars change depending on whether you are programming screens

or logic

blocks.

Project Information Window

The left section of the main screen displays the project in a

directory

structure with folders and subfolders for screens, logic blocks,

tags, alarms,

data logging, and I/O and network configuration.

Screens and Logic Block Work

Area

The middle section of the main screen is the work area for

developing your

screens and logic. Configuration Windows® also appear

here when

their corresponding folder is selected in the Project Information

Window.

Screen/Object/Instruction

Properties

The right section of the main screen displays the individual

properties for a

selected screen, object, or logic instruction and allows the

properties to be

edited.Useful Features

Additional Resources

Watch Video

Click the links below to watch videos: |

|||||

|

MAPware-7000 Introdution  MAPware-7000 is the configuration software used to program all HMI +

PLCs. Use

just one software application to program both the screens that appear in

the

display as well as the logic that controls your system. Create projects

using

the tools and graphic images included with the software to provide a

functional user-interface for your control system. In addition, the

built-in

or expandable I/O can be used to control and monitor your system

utilizing the

logic instructions integrated in the software. The graphics program and

logic

program work together to provide complete control through the graphic

interface.

MAPware-7000 is the configuration software used to program all HMI +

PLCs. Use

just one software application to program both the screens that appear in

the

display as well as the logic that controls your system. Create projects

using

the tools and graphic images included with the software to provide a

functional user-interface for your control system. In addition, the

built-in

or expandable I/O can be used to control and monitor your system

utilizing the

logic instructions integrated in the software. The graphics program and

logic

program work together to provide complete control through the graphic

interface.

|

|||||

|

Meters and Bar Graphs

Display analog data such as temperature, voltage, current, and speed in

familiar easy-to-read

formats.

Meters

Analog meters display data on a circular scale. Use the meter's color

range to demonstrate safe to cautionary levels of operation. Display

data such as temperature, voltage, current, and speed in familiar

easy-to-read formats. Other features include:

Bar Graphs

Bar graphs are used to display data on a vertical or horizontal scale,

with up to four bar graphs on a single scale. Other features include:

Multiple Bar Graphs

The Multiple Bar Graph object represents up to four consecutive

8/16/32-bit registers as a bar chart whose proportional lengths

correspond to the quantity in each register. A multiple bar graph can

move in any direction (i.e. left to right, bottom to top, etc.) and

monitor the target registers as signed/unsigned integer, BCD, or

floating point values. The Multiple Bar Graph object supports title

bars, selectable colors, and number designators along the

Y-axis For more information on Meters or Bar Graphs, refer to the MAPware-7000 Programming Manual |

|||||

|

MQTT

MQTT (Message Queuing Telemetry Transport)

is a lightweight, low bandwidth

protocol that works between clients and a broker (server) to publish and

subscribe data (topics) among

devices.

Maple Systems MQTT Integration

Maple Systems Advanced HMIs, Smart X Series HMIs and HMC4000

Series HMI PLCs all support the MQTT

standard version 3.1.1, while the HMC4000s will also support version

5. These products can function

both as MQTT Brokers (Servers) and MQTT Clients.

Typically, HMIs are used as MQTT Clients to publish process data to a central MQTT Server. Some examples of commonly used MQTT Brokers, which are supported by all Maple Systems MQTT-capable products, include Mosquitto, HiveMQ, RabbitMQ, and EMQX. The Smart cMT Series also supports Public Cloud Provider Integrations for MQTT, including those of Amazon AWS, Google Cloud, and Microsoft Azure. Additionally, the Smart cMT Series supports the Sparkplug B MQTT specification, which is designed to make it easier to track the state of sessions (connections) between the Client and Server. Various SCADA systems, such as Ignition by Inductive Automation, include built-in support for Sparkplug B, as does RabbitMQ via the MQTT plugin. Maple Systems Industrial PCs , Box PCs, and Panel PCs are the perfect host system for SCADA software and MQTT Server software. MQTT is supported in Web Studio SCADA software, the license for which can be bundled with your purchase of any Industrial PC by Maple Systems.

MQTT Topic Publisher

(Smart X Series only)

Data is organized into Topics in MQTT. Maple Systems HMIs can

publish data either periodically

(Time-based) or whenever a value changes (Trigger-based; a.k.a.

"Report by Exception").

Data are separated into individual Tags (values) and then published under a given Topic. MQTT Topic Subscriber

Any MQTT Client can subscribe to Topics via the MQTT Broker,

whether that Broker is running on

another HMI, or, as is more often the case, on another PC,

Cloud-based Server, or SCADA System.

Clients can subscribe to all topics, or just specific topics, from

the Broker.

Read more about MQTT, download supporting documentation, and find

out what Maple Systems hardware

supports MQTT, click here.

|

|||||

|

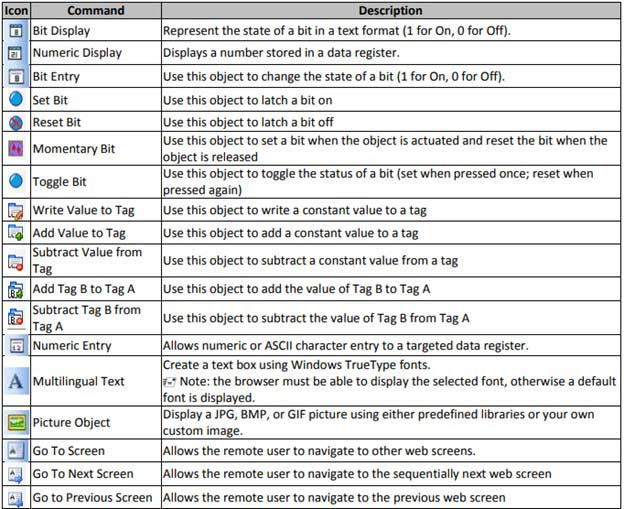

Objects – Bit/Coil Based

The MAPware-7000 software provides many options for displaying and

writing to bit/coil registers. Bit/coil registers are two state

registers that are used to represent an 'ON' and 'OFF' condition. Bit

registers often display lamps or buttons that control a target bit.

Bit Lamp

Bit lamps indicate the current state of a bit register using a

graphic image (i.e. lamp) or text (i.e. ON/OFF). When a bit lamp is

on a screen that is currently displayed on the unit, the unit

continuously polls the target bit register to determine which state

image to display.

Bit Display

Bit Display indicates the current state of a bit register using two

predefined messages (i.e. ON/OFF). The current value read in the

targeted bit/coil message determines what message displays. Messages

can be of varying length (maximum of 40 characters). When a bit data

display is on the screen, the unit continuously polls the target bit

register to determine which message to display.

Set-Bit

The Set Bit button sets a targeted bit/coil. The button displays

with either text labels or a graphic image to represent two states.

When a set bit button is on screen, the unit continuously polls the

target bit register to determine which state to display (feedback

tag must be enabled to display two states).

Reset Bit

The Reset Bit button resets (clears) a targeted bit/coil. The button

displays with either text labels or a graphic image to represent two

states. When a reset bit button is on screen, the unit continuously

polls the target bit register to determine which state to display

(feedback tag must be enabled to display two states).

Momentary Bit

When a momentary bit button is on screen, the unit continuously

polls the target bit register to determine which state to display

(feedback tag must be enabled to display two states).

Toggle Bit

The Toggle Bit button alternates setting and clearing a targeted

coil each time the button is pressed. When pressed by the operator,

the unit reads the current value of the coil, and then sends a

command to set or reset the coil depending upon the value read. The

button shows text labels or a graphic image that is used to

represent two states. When a toggle bit button is on screen, the

unit continuously polls the target bit register to determine which

state to display (feedback tag must be enabled to display two

states).

Bit Entry

Bit Entry is used to set/clear a targeted bit/coil. Two predefined

messages display according to the current value read in the targeted

bit/coil. Messages can be of varying length (maximum of 40

characters). When a bit entry is on a screen that is currently shown

on the display, the unit continuously polls the target bit register

to determine which message to display.

For more information on Bit/Coil based Objects, refer to the MAPware-7000 Programming Manual or watch one of

our videos:

Read and Write Objects Quick Buttons and Multi-Task Buttons Basic Objects and Animation Properties |

|||||

|

Objects – Register-based

There are many options for displaying and writing to 16/32-bit

registers. Register-based objects display the value in an internal or

PLC register and allow the operator to write new values. Register-based

objects can also display predefined messages or images depending upon

the 'state' or range of values in the register.

Word Lamp

Word lamps display predefined text labels or images shown according

to the 'state' of the target address. Each state represents a single

value or range of values tied to a particular text label or image.

The unit continuously polls the target register to determine which

state image to display. A maximum of 32 states are supported. Word

lamps are used where more than two choices are required. For

example, a tri-state condition with Run, Auto, and Manual modes may

be indicated using a word lamp.

Numeric Display

Numeric Display shows the current value of an 8/16/32-bit register.

The value can be displayed using a number of formats (i.e. signed,

unsigned, floating point), and special effects (ex. flash, color,

visibility). The numeric display object supports linear scaling

(engineering units) with the ability to scale the read value based

upon two mathematical operations. When a numeric display is on a

screen of the unit, the unit continuously polls the target register

to show the current value.

Message Display

Message Display shows a predefined set of messages depending upon

the value read in a targeted register. Messages can be of varying

length (max of 40 characters). Maximum number of messages is 255.

Note: if the value read from the targeted register is not within any of the predefined ranges, then the message displayed is blank. When a message data display is on a screen of the unit, the unit continuously polls the target register. Numeric Entry

The Numeric Entry shows the current value of an 8/16/32-bit register

and allows the operator the ability to write a new value. The value

displays using a number of formats (i.e. signed, unsigned, floating

point, and ASCII). The numeric entry object supports linear scaling

(engineering units) with the ability to scale the read value based

upon two mathematical operations. When a numeric entry is on a

screen of the unit, the unit continuously polls the target register

to show the current value.

Multi-Task Single-State Button

The Multi-Task Single-State button performs a set of predefined

tasks whenever the button is pressed. The button displays with text

labels or a graphic image that represents two states. When a

Multi-Task Single-State button is on screen, the unit continuously

polls the target bit register to determine which state to display

(feedback tag must be enabled to display two states).

Multi-Task Multi-State Button

The Multi-Task Multi-State button performs a set of predefined tasks

whenever the button is pressed. The tasks performed depend upon

which 'state' the button is in when pressed. The button displays

with text labels or a graphic image to represent the states.

Whenever the button is pressed, the object performs the programmed

tasks for that state. The unit continuously monitors a target tag

address to determine which state the button is in.

For more information on Register-based Objects, refer to the MAPware-7000 Programming Manual or watch one of

our videos:

Read and Write Objects Quick Buttons and Multi-Task Buttons Basic Objects and Animation Properties |

|||||

|

Objects – Tag Based

Screens and tags are not useful in and of themselves. Tags contain data

that represent machine operation, but without a means of interacting

with this data there is no way for an operator to understand or control

what the machine is doing. This section explores the various graphic

objects a programmer can place on the screen, exposing program data to

the operator, and fulfilling the Human Machine Interface function of the

unit.

General Object Properties

Object Properties control an object's appearance and function. The

programmer can configure these properties using the Property Grid

which displays the properties of the currently selected object. Most

of the objects placed onto a screen share common properties such as

color, border, label, line color, font, language, text, feedback,

style, and overall properties.

Flash Animation

Dynamically 'flash' selected object. 'Flash' means the object

displays on screen periodically depending upon the value in a tag

register. This can indicate an alarm condition or attract the

operator's attention.

Visibility Animation

Use this feature to make the object disappear. A tag address

monitored to determine when the object becomes invisible made

visible only when needed. This helps to reduce clutter on screen and

focus the operator's attention to the area of the screen that is

most important.

Flash

This is similar to the Flash Animation feature described above

except a tag register does not control this option. Therefore, if

enabled, the Flash feature continues as long as the object

displayed.

Simple Drawing Tools and Static

Objects

The MAPware-7000 software provides many drawing tools used to create

simple graphics on a screen. Sophisticated static objects are also

available to display graphics or text.

For more information on Tag-based Objects, refer to the MAPware-7000 Programming Manual or watch one of

our videos:

Read and Write Objects Quick Buttons and Multi-Task Buttons Basic Objects and Animation Properties |

|||||

|

Offline Simulation

Run your project in simulation mode, giving you the ability to test your

project on the PC prior to downloading it to your unit. With the Offline

Simulation option (Project > Run), the computer can display a copy of

the HMI + PLC on-screen, simulating how your project will look and

operate in the HMI + PLC. Logic simulation is also available with

programming with IEC61131-3. (Note: Native Ladder Logic Blocks are not supported in Offline Simulation mode.)

For more information on Offline Simulation, refer to the MAPware-7000 Programming Manual.

|

|||||

|

Real-Time Clock

The internal battery powers the real-time clock (RTC) when the unit is

not powered by external 24VDC. Normally, the internal battery should be

able to provide power to the RTC for approximately 20 years (@25°C).

Reading the Date/Time

The Clock objects (Time and Date) are used to display the date and

time on an HMI + PLC screen. Each field of the RTC data can also be

read and individually displayed on screen by using the designated

system word registers (SW10 thru SW16) in the tag database.

For more information on the Real-Time Clock, refer to the MAPware-7000 Programming Manual.

|

|||||

|

Real-Time Monitoring

MAPware-7000 offers the ability to run your application on your unit

while going online with it and simultaneously monitoring the logic in

real-time from your PC. This important testing capability allows you to

monitor and analyze the functionality of your application as it actually

runs.

For more information on the Real-Time Monitoring, refer to the MAPware-7000 Programming Manual.

|

|||||

|

Real Time XY Plots

XY Plot (single point): Plot the value in one

register against the value in another register. A single point is

displayed on the plot, the position of the point changes as the

values in the registers change over time. Reference lines can be

added to the grid to help determine if the data points are within an

acceptable range. An error message will display along the bottom of

the plot when values are read that are outside the specified grid

range. XY Plot (multipoint IEC programming mode only): In this mode, data points (historic) previously recorded are not erased when new data points (current) are read. Up to 100 historic data points can be displayed. Data can be retentive so that it is maintained even if power is removed from the HMI + PLC. When the Data Point with Line and Line Only features are used, a line is drawn between each data point. Other features include:

For more information on the Real-Time XY Plots, refer to the MAPware-7000 Programming Manual.

|

|||||

|

Recipes

Easily manage batch processes by selecting different batch variables

used for a specific process with the simple push of a button.

Using Recipes

A Recipe is an arrangement of internal registers in the unit's

non-volatile memory that are used for pre-defined process control.

The advantage of using recipes is in batch processing applications

in which a series of unique values or set points are required to

produce or perform an operation. If there are several different

batches or recipes, then the recipe features makes it easier for the

plant floor operator to select which recipe they need for the

current job, downloaded the preset values to the PLC from the HMI

with the press of a button, and start the job.

Transfer Recipe

The Transfer Recipe button is used to copy predefined constant

values from a consecutive set of internal HMI memory tag addresses

to a set of PLC memory tag addresses. Up to 100 values can be

transferred per button created.

Upload Recipe

The Upload Recipe button copies predefined constant values from a

consecutive set of PLC memory tag addresses to a set of internal HMI

memory tag addresses. Up to 100 values can transfer per button

created.

For more information on the Recipes, refer to the MAPware-7000 Programming Manual, or watch

our video,

HMC7000

Recipes

. Recipe Database

The Recipe Database is a feature in MAPware-7000 v2.36+ that when

enabled allows the user to create a local database of recipes,

organized into groups. Within MAPware-7000, recipes and groups can

be created, recipe data edited, and registers and bits can be

assigned to various functions so that recipes can be created,

edited, deleted, and searched for at runtime from the HMC screen.

Recipe data can be uploaded and downloaded to the HMC via USB drive

through the System Settings Menu or a task button placed on a

screen.

This feature is currently available for the HMC4000 series.

For more information on this feature, see our How to Program Recipes tutorial.

|

|||||

|

Remote Access

Select models have a built-in web server that allow the remote user to

both view and modify data in the unit. Screens are displayed in the web

browser as if it were a website. Only text-based objects and static

images are supported in this type of screen.

Web Screens

Select models have a built-in web server, accessible from any

Internet web browser, allowing remote access to HMI/PLC data from a

remote computer on the Ethernet network or, if exposed to the

Internet, from anywhere in the world. A username and password are

required, ensuring security. The screen is displayed in the web

browser as if it were a website. Web screens allow the remote user

to both view and modify data in the HMI + PLC. Up to 10 simultaneous connections are allowed. The objects used on web screens are restricted to text-based data display / input objects, static images and navigation buttons. Up to 100 screens can be created using MAPware-7000. Up to 100 objects (i.e. text, bitmaps, bit and register data values, and buttons) are available per screen. Ten users can be connected to the MLC3 PLC simultaneously. The following objects are available for use on web screens:

For more information on this feature, refer to the MAPware-7000 Programming Manual.

|

|||||

|

Screens

Create customized screens using graphic images included with the

software or personalize them with your own custom images.

Screen Types

In MAPware-7000, you can configure or define a screen to be one

of the following:

Base Screen Create as many base screens as are required for your application. Use buttons or tasks to change from one screen to another. A base screen fills the entire area of the display.

Pop-up Screen A pop-up screen is displayed on top of a base screen and can be used to display additional information related to the base screen. A popup screen must be smaller than the underlying base screen.

Template Screen A template screen also fills the entire area of the display but is not called directly by a button or function key on the HMI + PLC. A template screen is displayed by attaching it to a base screen. When displayed, all objects on the template screen are underlayed on the base screen.

Keypad Screen A keypad screen is a specialized pop-up screen used to enter numbers or ASCII characters in a data entry display. There are four pre-defined popup keypad screens: numeric keypad, hex keypad, bit keypad, and ASCII keypad. These can be edited and custom keypads can be created.

Web Screen

Web screens are viewed by connecting to the HMI + PLC's built-in web server with an Internet browser. The HMI + PLC's web screens display in the browser as if it were a website, providing remote access to the unit for viewing system status information. See Remote Access feature for more information.

For more information on Screens, refer to the MAPware-7000 Programming Manual or check

out our Videos:

Getting Started with MAPware-7000 Part 5 and Part 6 Screen and Tag Creation |

|||||

|

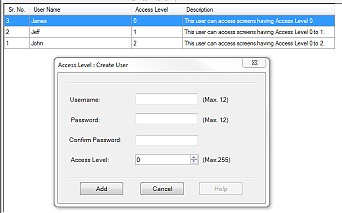

Security and Passwords Access Levels

The Access Level feature available on select models allows you to

create users and passwords assigned to different access levels.

These levels can then be assigned to screens and used to restrict

access. When accessing a protected screen, a "Screen access denied"

error will show for users that have not logged in or do not have the

required level of access. Additional features:

Protecting Project Screens

Screens can also be individually protected by creating a

password in the Screen Properties dialog box. Once entered, any

future operator must enter the correct screen password using an

on-screen numeric pop-up keypad in order to get to that

screen.

Intellectual Property ‐

Project Password

MAPware-7000 offers the ability to password-protect the entire

development project to protect your intellectual property.

Creating an optional project password is a way to protect your

project (and intellectual property) from unauthorized

modification. The password can be up to 8 alphanumeric

characters in length. If a password is created in the project

configuration window, the correct password must be entered to

open the project file for review or editing.

Note: A project password is not required. Care must be taken to remember the project password, as it is not recoverable if forgotten. It is not possible to recover a project if the password has been forgotten or lost. Remote Access

All remote access web screens are protected and require a

username and password.

Backlight/Screen Saver

Password Security

The HMI can be configured to go into a backlight/screen saver

mode after a predefined length of time, up to 90 minutes,

without any operator input. The operator reactivates the screen

by touching it, but a username and password can be configured

before normal operation is restored. This can be used as an

auto-logout type feature at the end of shifts, ensuring that

only authorized personnel can reactivate the HMI to begin the

next shift.

For more information on Security and Passwords, refer to the MAPware-7000 Programming Manual. |

|||||

|

Tag Database Tags are names assigned to internal memory registers of the unit, contacts of an expansion module, and any PLC data registers/coils of an external PLC. Some system tags are predefined when you first begin a project. Other tags are created by the programmer. For example, you must create and assign a tag to every PLC memory address that you wish to read/write to. When using the optional I/O Expansion modules tags are created in order to use them. The Tag Database collects and stores all tags for review and editing. Once a tag is assigned, you can easily link any object (i.e. bit lamp, numeric register, etc.) to the tag. Tags have several advantages:

For more information on Tags, refer to the MAPware-7000 Programming Manual, or watch our video, Screen and Tag Creation, or Part 3 of our Getting Started with MAPware-7000, Adding and Initializing Tags. |

|||||

|

Tasks

tasks can be performed by pressing a button when a particular screen is

displayed or when the HMI +

PLC is powered on.

Task Actions

An integral part of the MAPware-7000 configuration software is the

ability to create tasks. Tasks are pre-defined actions executed by

the HMI + PLC program. More than 50 different actions can be

performed utilizing the Task feature. The number of tasks created is

limited only by the total amount of available memory in the HMI +

PLC. Actions include:

Task Triggers

Each task has two fundamental components: the action taken when the

task is activated and the triggering mechanism causing the action to

be performed. Tasks can be triggered when:

Assigning

Tasks

Tasks can be assigned to:

For more information on Tasks, refer to the MAPware-7000 Programming Manual, or watch

our video,

Tasks and Function Keys.

|

|||||

|

VNC Server

The HMC4000's built-in VNC server allows users to remotely monitor their process. For more information on this feature, see our How to Connect Remotely to an HMC4000 Series using the VNC Viewer Application tutorial.

Remote Monitoring and Control

All of Maple System’s HMC4000 Series HMCs possess a VNC server (included at no additional cost) which allows them to be remotely monitored from a number of devices (laptops, desktop PCs, tablets, and cell phones (iPhone, Droid, Blackberry, or any other smart device with VNC client capability).

VNC Server Benefits

In recent years, there has been a vast improvement in HMC remote monitoring abilities. Remote control of the HMC means remote control of the PLCs and controllers that command the automation process. This opens a new universe of logistical improvements in the control process. Monitoring your automation process from a remote location has never been easier and offers many process control benefits. What does that mean for the everyday operation of your plant?

Real-Life Applications

|