Stainless Steel Industrial PCs

Industrial PCs with a stainless-steel enclosure, and stainless-steel front bezel on our touchscreen models, may be customizable. Our Touchscreen Industrial PCs can be IP66 when panel mounted into an enclosure. The rugged 10.1”, 12.1”, 15.0”, 19.0”, and 21.5” Stainless Steel Panel PCs feature capacitive touchscreens that withstand even the toughest environments and are ready for high-pressure, high-temperature regular washdowns. Ideal for food & beverage, pharmaceutical, chemical industries, and consumer packaged goods processing operations. Our Class 1, Div 2 Industrial Panel and Box PCs feature either a SUS304 front Bezel with a IP66K/IP69K or 316 Stainless Steel Chassis with an IP66 rating on all sides. Extended temperature, high brightness, with optical bonded touchscreen options are available.

With a Windows® Operating System, these PCs are powerful computers that support any Windows® Software, powerful SCADA software such as Allen-Bradley’s FactoryTalk® View, Ignition™, AVEVA™ Edge and Wonderware®, or configure them using programming languages such as Visual Basic, Python and C++, providing you with flexible options.

Industrial PC Accessories

We offer custom communication cables to interface with over 300 protocols. Call us or see our Support Center for more details.

Why Stainless Steel?

Stainless Steel Industrial Panel PCs are ideal for applications in Food & Beverage, Pharmaceutical, & Consumer Packed Goods due to their anti-corrosion properties, resistance to high-pressure & high-temperature regular washdowns and low maintenance costs.

Rugged IP66/69K Capacitive Touchscreen

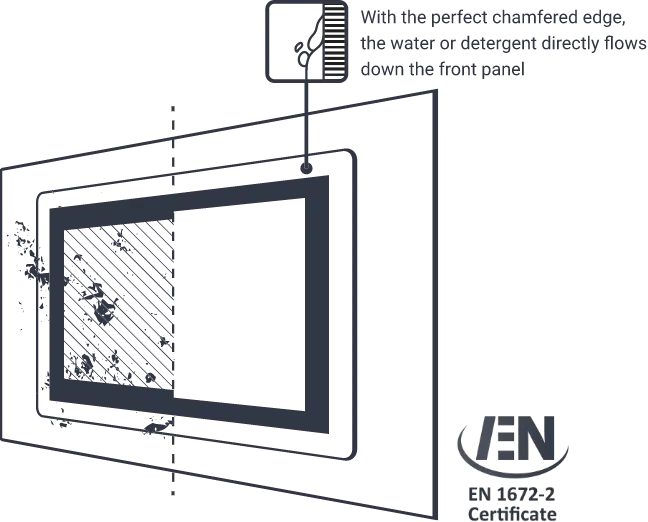

Our rugged PCs feature either a SUS304 front Bezel with a IP66K/IP69K rating or 316 Stainless Steel Chassis with an IP66 rating on all sides, making them the preferred choice in environments requiring frequent high pressure and high temperature washdowns.

Maple Systems stainless steel PCs meet the international food safety grade requirement, EN 1672-2 certification for optional, and DIN 42115 Part 2 for the durability of chemical substances and the sealing material meet FDA 21CFR 177.2600.

Why Class 1 Division 2?

Class 1 Division 2, or C1D2, is one of the most important factors to consider when looking for rugged industrial PC to use in hazardous industries. Any electronics being used in a potentially dangerous environment or around flammable hazards must be C1D2 certified to prevent dangerous explosions and ensure worker safety.

The Classes define the type of explosive or ignitable substances which are present in the atmosphere such as:

- Class I locations are those in which flammable vapors and gases may be present.

- Class II locations are those in which combustible dust may be found.

SCADA Software

AVEVA Edge, formerly known as Indusoft Web Studio, is a powerful HMI/SCADA software package for a wide range of industrial applications. With easy-to-use commands/tool bars and a Microsoft Windows™ environment, Aveva™Edge's feature-rich application puts you in the driver's seat of creating your industrial process.

Industries We Serve

Let us serve as your guide, making it an easy process to join the next evolution of automated control

Whether your goal is to increase throughput, elevate quality control, enhance traceability, protect the brand image and consistency, reduce recalls, improve personnel safety, or all the above, we can help. Today's technology offers innovative solutions for industrial process control issues. Whether it's sorting, filling, forming, packing, or inspecting, our product can help you address your unique challenges head on.

Learn more about the industries we serve and discover why more and more companies are choosing Maple Systems.

Read Our Case Studies

The Stainless-Steel enclosure makes this Industrial Panel PC the right choice for the food and beverage industry

Our customer is a leading OEM manufacturer of custom stainless steel processing equipment and a preferred provider of quality products and services to the cheese, dairy, food, beverage, and other sanitary industries. Our Stainless-Steel PCs meet the international food safety grade requirement, EN 1672-2 certification; DIN 42115 Part 2 for the durability of chemical substances; and FDA 21CFR 177.2600.

Read how choosing a Maple Systems Stainless Steel Industrial PC with capacitive touch screen and a Windows OS met their requirements.

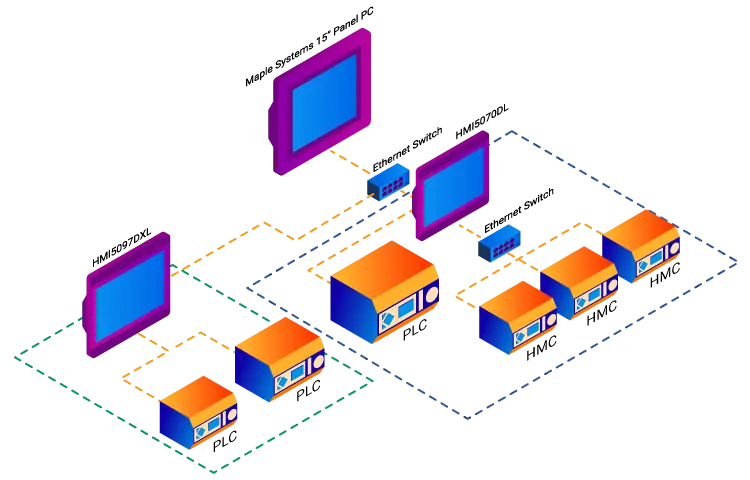

Supervisory Control and Data Acquisition (SCADA)

Supervisory control and data acquisition (SCADA) is a control system architecture that uses computers (PCs), networked data communications, and human machine interfaces (HMI) for high-level process supervisory management but uses other peripheral devices such as programmable logic controllers (PLC). As you can imagine, this can take on a wide range of functionality, complexity, hardware, and software solutions.

We offer all the elements you need to create your own level of supervisory data acquisition and control, from the simplest stand-alone machine to sophisticated multi-device networked production line(s), all the way to enterprise-level operations and IIoT functionalities leveraging cloud connectivity.

To learn more about how our products work together to create scalable SCADA solutions, visit our SCADA solutions page

Customize your HMI, HMI+PLC, or PC

Highlight your brand and differentiate your machine with a custom label

Company branding is a significant aspect of business marketing. By using custom labels on your products, you can create an identity to gain recognition from customers and potential buyers. It helps consumers recognize that the product was made by your company. Having this type of brand recognition can help your business stand out from competitors.

Our Custom Labels:- Fit Your Product Perfectly

- Offer Professional-Looking Packaging

- Strengthens Your Marketing Efforts

- Provides an Identity to Your Business

Manuals and documentation for products supported by Maple Systems Industrial Panel PC products.

Manuals & Guides

Need additional support?

Visit our FAQ section for more info.