MapleLogic Programming Environment

MapleLogic is the configuration software used to program our PLCs. Create projects hassle-free by utilizing the tools and features included in our user-friendly software.

- Free full version software

- Quick Start Guides and Video Training Center

- Tutorials on common topics with sample projects

Features Overview

Workspace

Our intuitive interface makes programming a breeze

Programs

Efficiently create your project with the help of our pre-made programs

Simulation

Test and troubleshoot programs without the need to use a physical PLC

Data Analysis

Monitoring tools allow you to easily analyze your system

PLC Diagnosis

Comprehensive error detection and troubleshooting tools

Security

Enhanced security features ensure your project is protected

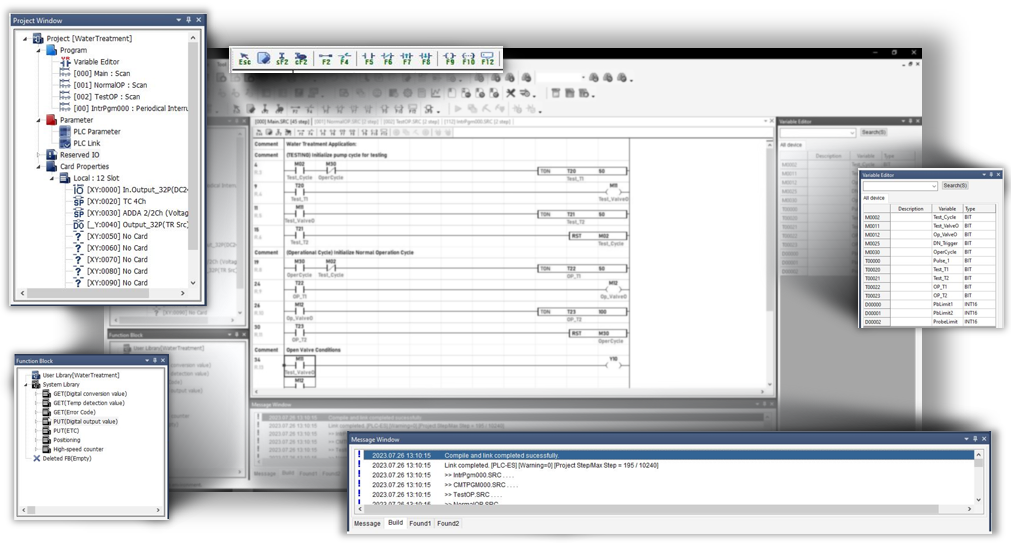

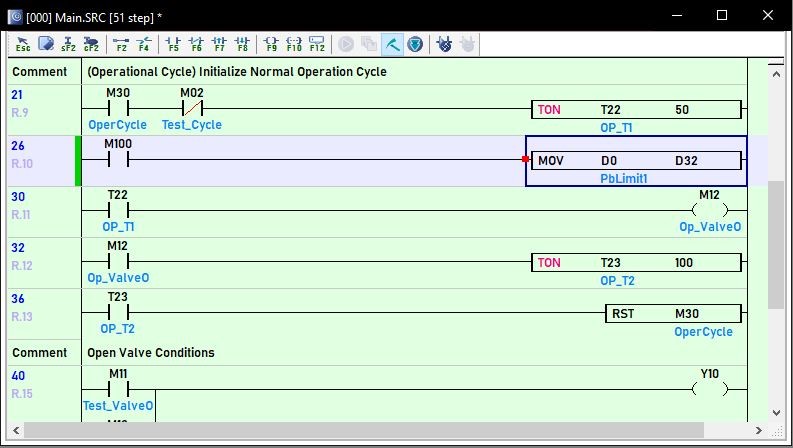

Programming Workspace

Project Window

Manage your project efficiently with our detailed project panel and adjust your project to your work style

Convenient Instruction Shortcuts

Use keyboard shortcuts or click on the instruction icons to start programming

Variable Editor

Edit and display all variables being used in a project

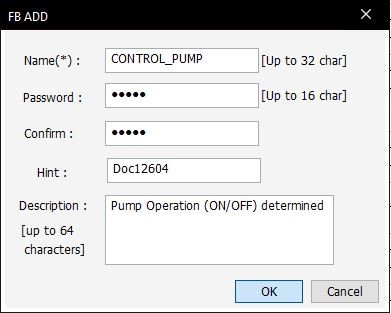

Function Block Window

Create your own function blocks and save them for use in other projects or use some of our preprogrammed functions.

Message Window

Process results display any errors or faults within your project allowing you to quickly detect and resolve issues

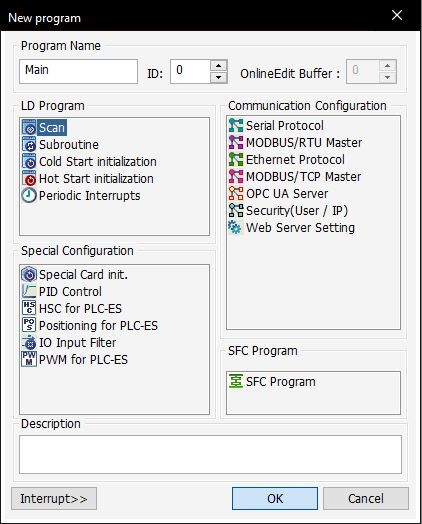

Creating Programs

Conveniently create PLC programs using our easy-to-use interface. Create programs that continuously run in a loop using our “Scan” program, create a subroutine that is called within your scan program, or create a program that runs at a given interval using our “Periodic Interrupts” program. We also offer cold start and hot start initializations for those projects that require that extra fine-tuning.

Streamline the creation of specialized programs by using our Special Configuration programs. These programs reduce the hassle of creating your own PID Control, High-Speed Counter (HSC), Positioning, IO Filtering, and Pulse-Width Modulation (PWM) programs and allow you to spend your time more efficiently.

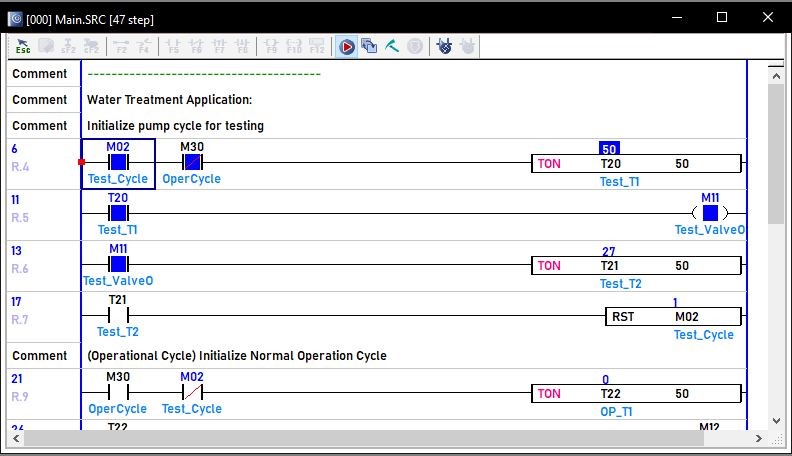

Simulation

MapleLogic provides a comprehensive simulation mode allowing you to create and test fully functional projects prior to downloading to your PLC. Evaluate your project and identify errors that can influence the performance of your application. Furthermore, our simulator allows you to test critical conditions your PLC can experience without putting your equipment at risk.

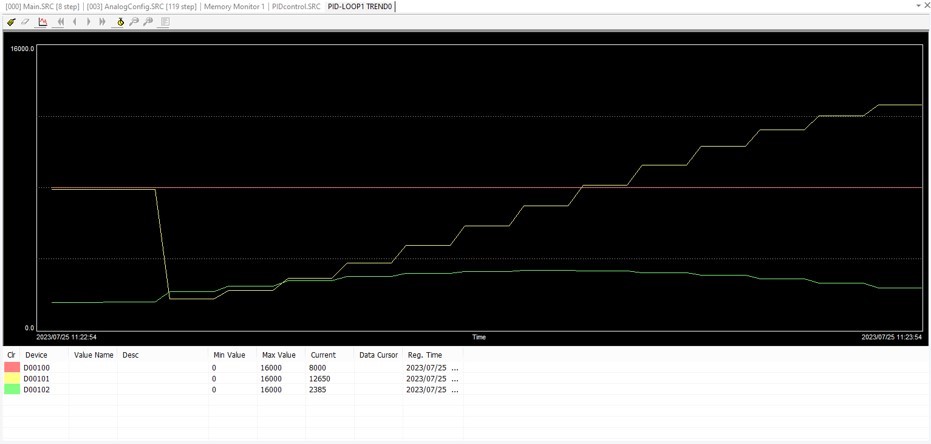

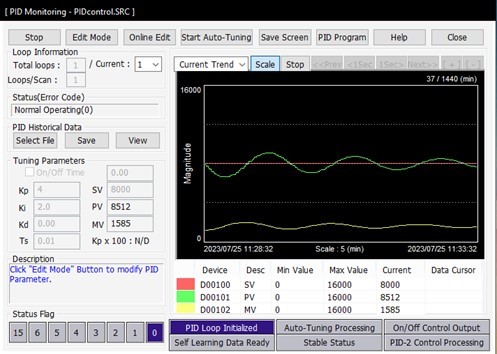

Data Analysis

When programming a PLC it’s important to ensure your control system is working properly, that’s why with MapleLogic software we focus on giving you the tools you need to ensure you have the information to make those informed decisions.

Device Trend allows you to monitor your devices in real-time, or historically, and save that data for further analysis. In addition, our special programs have dedicated monitoring tools that allow you to fine-tune your configuration settings online – this includes live auto-tuning of your PID program.

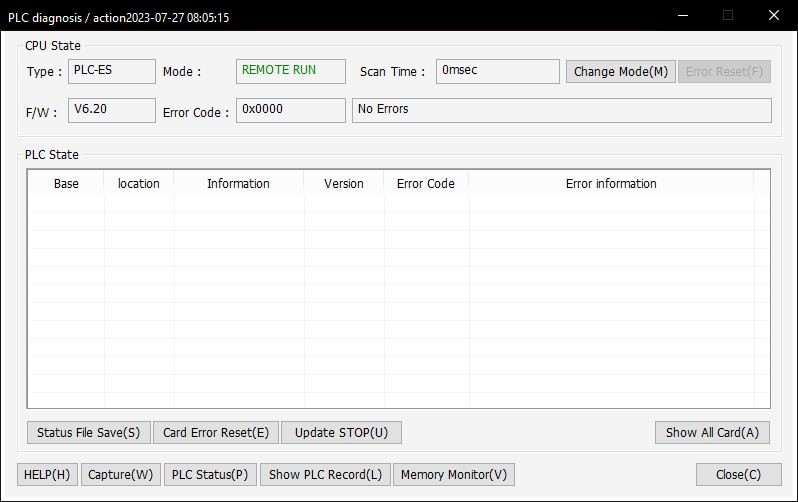

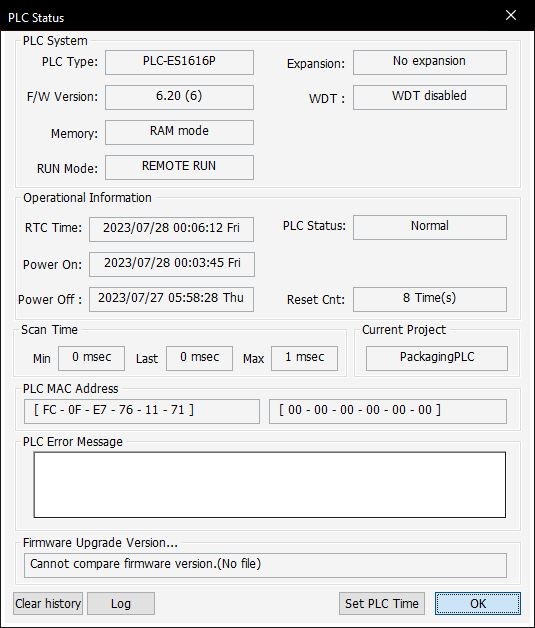

PLC Diagnosis

MapleLogic offers high precision fault and error detection – in the unpredictable event of an error you can quickly diagnose the issue. The PLC diagnosis will give you precise information on which device the error is occurring and information on how it may be resolved.

Security

Ensure your project is only accessed by qualified personnel with our robust security system. Easily choose what parts of your project need security for instance: create a project-wide password to ensure only you and select personnel can access the project, create passwords for single or multiple programs to safeguard configuration settings or other important programs while still allowing personnel to access the rest of the project, and/or protect your custom function blocks so users can utilize them but not alter the program within.