Human Machine Interfaces (HMI)

Human Machine Interfaces (HMI) make your automation, data monitoring, and networking easy with our user-friendly HMIs and IIoT ready edge-devices. Our HMI software and award-winning customer service are a few more reasons for choosing an HMI that will give you the power and flexibility to streamline your automation processes.

Choose from touchscreen HMIs with displays of 4.3", 7”, 9.7”, 10”, 12”, 15”, 15.6", or headless HMIs and edge-gateways. Our industry-leading features include Capacitive Touchscreens, Wi-Fi, Dual Ethernet, Remote Access, Class 1 Div 2, IIoT protocols such as MQTT, Ignition, SparkPlug B , and more.

Our CID2 certified HMIs are designed to keep operators and

their environment safe

View Products >>

Remotely access your control system with your smart phone,

tablet, laptop, or PC

View Products >>

Featuring 1000nits, this HMI solution is ideal for light

intensive environments

View Products >>

Combined one of our HMIs with a coupler and remote I/O

controlled using CODESYS

View Products >>

Our wi-fi HMIs add flexible connectivity and consolidates

solutions into a single package

View Products >>

HMI Accessories

$35.00

More Details$45.00

More Details

We offer custom communication cables to interface with over 300 protocols. Call us or see our Support Center for more details.

Connecting a Maple Systems HMI to a Maple Systems PLC couldn't get easier

Whether you are new to Maple Systems or are familiar with our HMIs, pairing one of our powerful HMIs with a Maple Systems PLC is easy.

Our fully functional, low-cost PLCs with built-in I/O offer you the ability to add control functionality to your project and maintain your Maple Systems HMI. These powerful units are fully functional PLCs with digital and analog I/O that support high-speed counters and PWM (pulse width modulation). Analog I/O options support several voltage and current modes as well as RTD (resistance temperature detection) and thermocouple sensors to measure temperature.

Read More Here

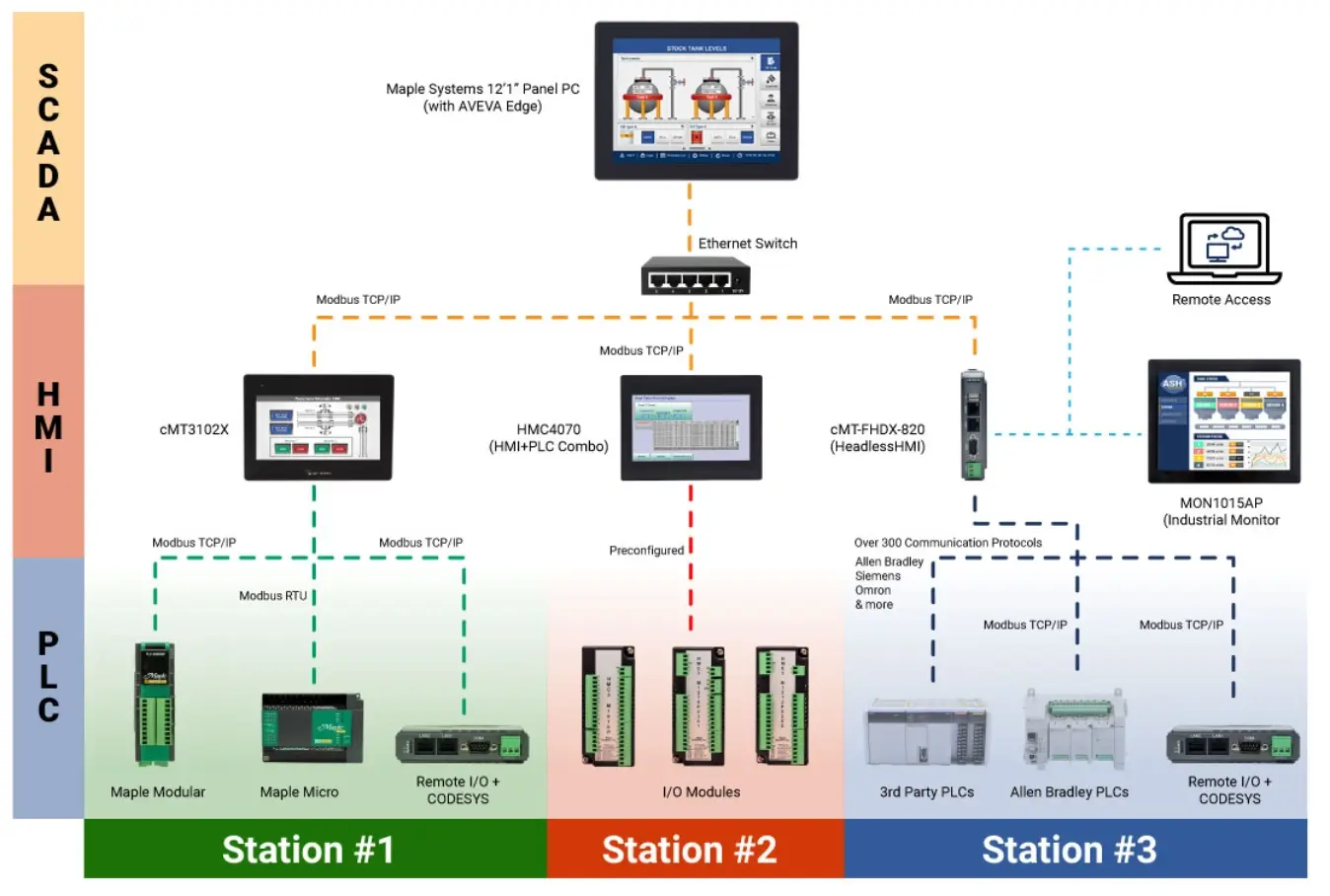

SCADA and PLCs

Supervisory Control and Data Acquisition (SCADA) are systems that include various devices that allow users to monitor, control, and optimize industrial processes. SCADA systems can include different combinations of devices such as PLCs, Human Machine Interfaces (HMIs), monitors , databases, and more, to solve automation challenges.

PLCs in SCADA systems play an integral role by acting as intermediary between field devices and the connected system. PLC can receive input from sensors and send commands to actuators based on predefined logic while also sending and receiving information from other devices within the system.

A basic SCADA system that can be seen in small-medium scale operations is an HMI-PLC system. This system allows an operator to monitor and respond to the real-time status of the PLC, and the corresponding field devices, by way of the HMI's interface. In real world application this can give a water treatment operator the ability to remotely shut down a pump for maintenance, check the status of a sensor, and/or stop operation all together in the case of an emergency.

Learn More About SCADA Systems

Class I, Division 2 HMIs

Maple Systems offers Class I Div 2 certified HMIs designed to keep operators and their environment safe

Any electronics being used in a potentially dangerous environment or around

flammable hazards must be C1D2 certified to prevent dangerous explosions and ensure worker

safety - and we have solutions to meet this strict requirement.

Our popular C1D2

HMIs are used in industries including oil and gas, mining, painting, chemical processing,

pharmaceutical, food processing, and more.

Headless HMI

Our headless HMIs are perfect for systems where a fixed visual interface is not needed

These powerful HMIs are DIN rail mounted without a built-in display that allow you to monitor PLC operations, gather data, and remotely access your control system on your Apple/Android smart phone, or your own tablet/laptop/PC. Our HDMI®-enabled HMI works with screens of any size, making screen size no longer a limitation in your application.

Explore Headless HMIsHMI + Remote I/O + CODESYS

Combine the power of CODESYS with one of our CODESYS capable HMIs and Modular IO to create an innovative control solution that can tackle the most demanding applications

This unique architecture saves time, hardware cost, communication cabling, and valuable control cabinet real estate, without compromising on the CPU resources real time applications require. CODESYS provides a control solution that is one of the most complete implementations of the IEC 61131-3 standard for PLC software on the market. We offer several innovative hardware solutions serving as the perfect platform for your CODESYS HMI or PLC project.

Explore our CODESYS solutions

High Brightness HMI

Create a high-brightness HMI by pairing our HDMI-enabled headless HMI with one of our high brightness industrial monitors

Our high brightness/sunlight readable projected capacitive touchscreen monitors with 1000nits are ideal for applications in Industrial Automation, Healthcare, Finance/Banking, Education, Gaming/Entertainment, Home Automation, Retail, and Transportation, and pair easily with our HDMI-enabled headless HMI. The projected capacitive technology allows use with any type of gloves.

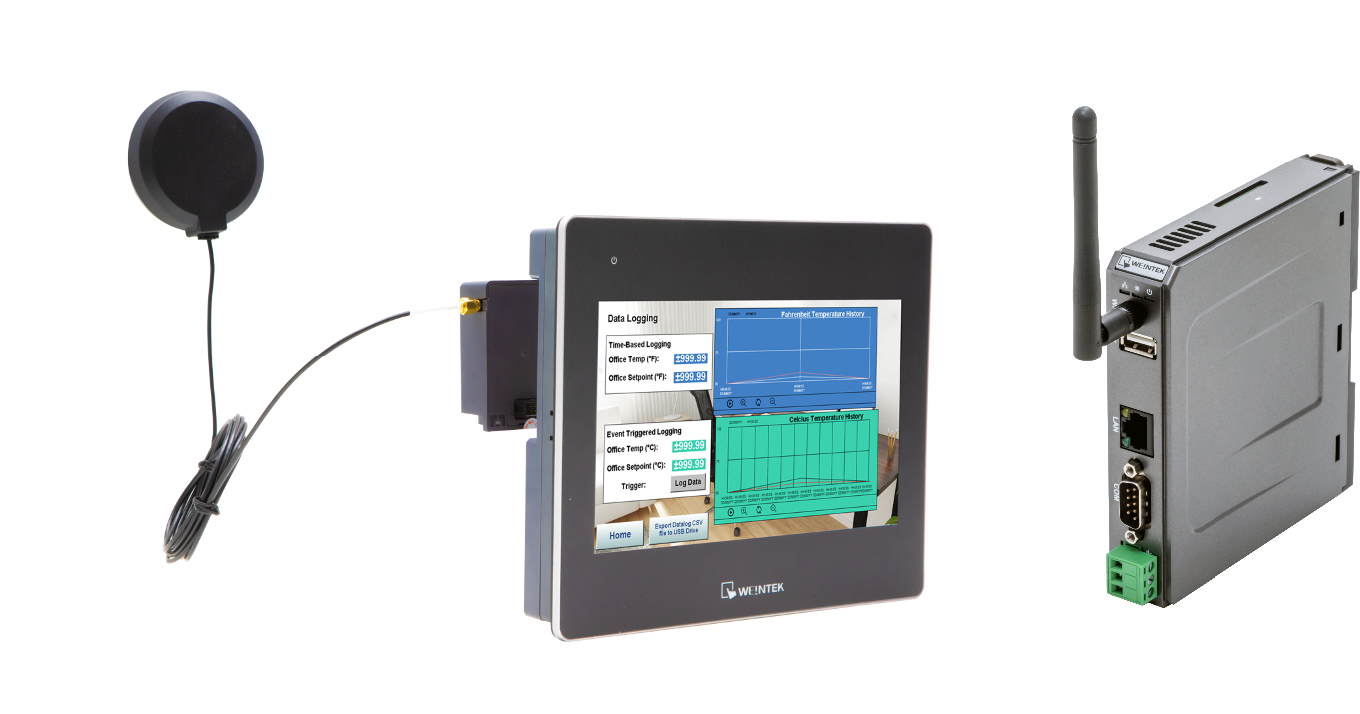

Explore High Brightness HMIsWi-Fi enabled HMIs

These powerful HMIs are ideal for mobile applications, remote monitoring, and device maintenance

The HMI Wi-Fi access point allows smartphones or laptops to wirelessly

connect to HMI allowing monitoring and maintenance of the HMI through your connected device.

The Wi-Fi access feature can be easily enabled from a browser or on the HMI.

If a

fixed display is required, adding our wifi expansion module to a wifi-supported HMI creates

a flexible connectivity solution consolidated into a single package

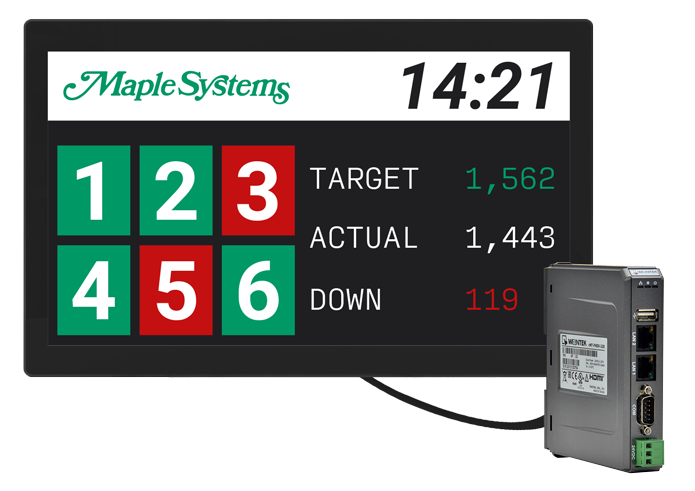

Create an Andon Station

The size of your HMI screen is no longer restricted – you can now display your real-time production data on a large, wall-mounted Status Display Station or Andon, easily visible from any plant floor location

Our HDMI-enabled unit is a powerful HMI with no display that converts any compatible TV or monitor into an Andon or Status Display Station. All HMI data and screens are displayed on an HDMI®-compatible monitor. This model divides the traditional all-in-one HMI into two, distinct parts: A data-processing unit and a separate visual display.

Explore our HDMI-enabled HMIsUser Friendly HMI Configuration Software

Free, powerful HMI configuration software for our HMIs provides the flexibility to create and deploy custom control applications suited to your unique industrial process. With support for over 300 PLC & controller communication protocols, EBPro enables our HMIs to seamlessly integrate with your new or existing system.

Programmable Logic Controller (PLC) Connectivity

With over 300 PLC & Controller communication protocols, these HMIs will easily integrate with your preferred PLC brands, including:

Allen-Bradley

Siemens

Omron

Emerson

GE

Panasonic

Mitsubishi

...and

many more

Customize your HMI, HMI+PLC, or PC

Highlight your brand and differentiate your machine with a custom label

Company branding is a significant aspect of business marketing. By using custom labels on your products, you can create an identity to gain recognition from customers and potential buyers. It helps consumers recognize that the product was made by your company. Having this type of brand recognition can help your business stand out from competitors.

Our Custom Labels:- Fit Your Product Perfectly

- Offer Professional-Looking Packaging

- Strengthens Your Marketing Efforts

- Provides an Identity to Your Business

In this exclusive Design Guide, we review the types of HMIs — as well as their basic functions and new and emerging HMI functions and connectivity options. The role of HMIs in IIoT operations and the trend towards standardization (for both open source and proprietary setups) is also covered.