What is a HMI?

From flipping a power switch to sending complex instructions during operations, users need a way to interact with the devices they are working with. The Human-Machine Interface (HMI) provides a point of contact between operators and their machinery that is a fundamental aspect of industrial control design. In this article we will explore the history and development of Human-Machine Interfaces, the current state of technology in this field, and what the future may hold for HMI technology as it evolves to suit the ever-increasing needs of industrial production.

Why Would I Want an HMI?

While the advancement of automated processes may have eliminated the need for direct human input in many cases, nearly all machines require human interaction to operate safely over time. Both plant supervisors and machine operators require quick access to plant information so they can make decisions swiftly and efficiently. An HMI provides that access, along with an entire control room worth of features integrated into a single unit. This allows users to quickly review feedback data and gain an overview of an entire operation without skipping a beat.

User Interface (UI): The means by which a user and a computer system interact.

Human Interface Device (HID): A device that allows a human to interact with an electronic system. Often used to describe input devices such as keyboards, mice, or touchscreens.

Human Machine Interface (HMI): A control panel, dashboard, or screen used to control machinery. Allows data input but also offers advanced features designed for industrial applications.

HMI technology advancements have significantly cut costs and boosted productivity, surpassing early expectations in control systems development. What once required an entire room worth of gauges and buttons has now been compressed into a single compact device.

HMI Device Types

Fusing visualization, communication, and control, HMIs on the market today can handle a multitude of different functions. As electronic components shrink in size and become more powerful, what once required an entire room full of dials, gauges, and buttons has now been compressed into a single compact device. Used for much more than collecting user input, high-end HMI systems have the potential to be a central hub for an entire operation.

With some exceptions, HMIs will generally include ports for device communication as well as an interface for human input such as a keypad. Manufacturers often combine these with a screen or indicators for feedback or displaying plant data. Moreover, the specific needs of a particular industry or application often dictate the design of each HMI model, leading to significant variations.

Choosing the HMI that is right for a project requires careful research and will depend on multiple factors. HMI devices come in a variety of shapes and sizes, with designs built for specific applications and environments. Getting a full grasp of project scope and environmental factors for a given project before buying a new HMI is extremely important. No matter what the requirements are, there is likely to be an HMI suitable for that purpose, with the majority falling into a few basic categories.

Touchscreen HMIs

Interface panels with hardwired buttons have their place, but when it comes to overall flexibility and user experience, touchscreen HMI panels are hard to beat. These panels are such a popular style of interface that they are what many people associate with the term HMI. The seamless integration of user input and display output offers obvious advantages, as it allows designers to add their controls and relevant data to individual screens tailored for specific needs. Operators can then navigate between screens as needed, enabling them to quickly switch gears and interact with dozens of devices without crowding a single screen with everything at once.

Headless HMIs

While most HMIs come equipped with a built-in screen and user interface, there are a few reasons why this may not be desirable. The headless HMI eliminates the screen and enables users to send video out through HDMI or network connection instead. Doing so greatly reduces the size of the unit, and allows the HMI processing and communication hardware to fit into tight enclosures or mobile stations where space is at a premium. Users can then connect directly to an external touch screen monitor or access it remotely via a web interface from any location with an internet connection.

HMI + PLC Combined

For those who want their hardware to have the smallest footprint possible, HMIs may now have integrated programmable logic controllers (PLCs). The HMI + PLC combo allows for enhanced data transfer speeds between the HMI and controller hardware while also reducing the time and space required for installation by eliminating the need for communication cabling.

OITs

Sometimes simpler is better. Though somewhat distinct from HMIs, Operator Interface Terminals (OITs) serve many of the same purposes as their more advanced relatives. OITs combine a physical keypad with a simple text or graphic display, offering straightforward interfaces well-suited for direct interaction or process monitoring at the machine level. OITs can still handle an impressive number of functions, and they may permit swapping out custom button overlays for specific applications.

Industrial PCs

Like OITs, this category falls outside of what many consider to be an HMI, but Industrial PCs are still worth mentioning for a few reasons. PCs may be used in place of an HMI in many cases, and can provide the same functionality plus a whole world of extra features. One of the advantages of using a PC is having the ability to easily upgrade the components as they age, reducing costs over time. Additionally, industrial PCs can come equipped with more powerful components, making them a good choice for complex operations that require faster processing than the typical HMI can provide. Industrial PCs may come in a panel configuration for easy mounting, or in a more traditional PC case.

HMI Software Features

Hardware specs are only one part of the picture. The full potential of HMI hardware is realized when combined with design software that is both feature-rich and user-friendly. Suppliers typically offer HMI design software that designers can use to program their devices, either for free or with a paid license. In many cases the manufacturer’s design software may work for multiple devices, but not all models will support every feature. Below are a few of the most common capabilities included with HMI programming software.

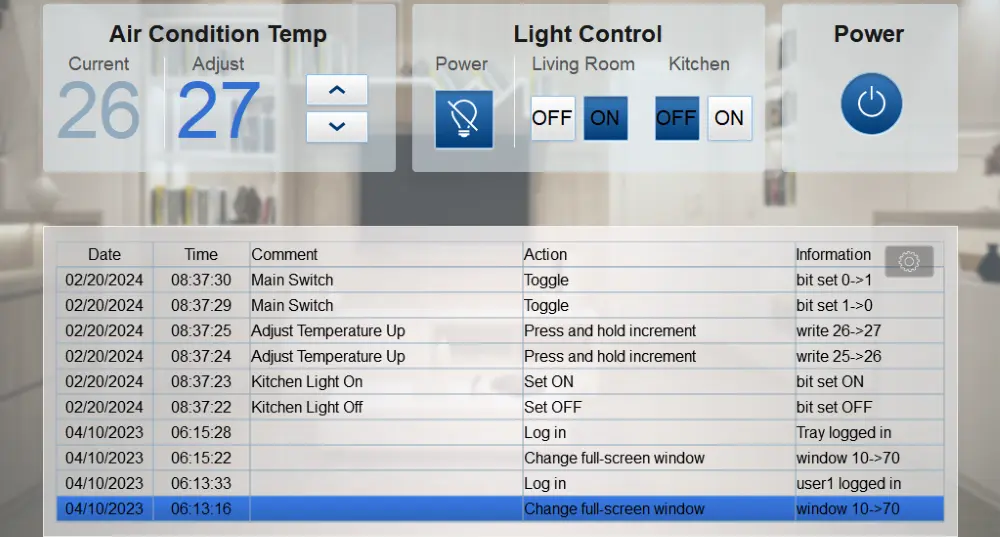

Customizable HMI Screens

- Create custom control dashboards that can be used for any number of applications.

- Tailor screens specifically for a given task.

- Organize relevant data so it is easy for operators to understand at a glance.

IIoT Protocol Support

- Communicate with IIoT enabled devices.

- Use protocols such as MQTT and OPC/UA to send messages from machine to machine, or out to the cloud.

Data Collection

- Collect sensor data from plant machinery.

- Store data logs in memory for future review.

- Send logs out on an automated schedule.

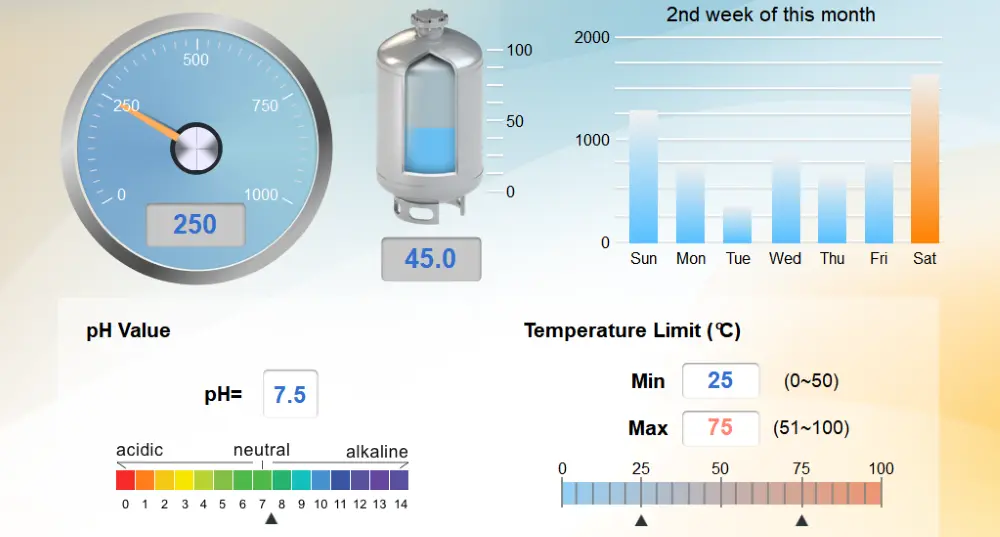

Visualization

- Organize relevant data in a format that can be quickly understood by operators.

- Include charts and graphic displays of plant information in real-time.

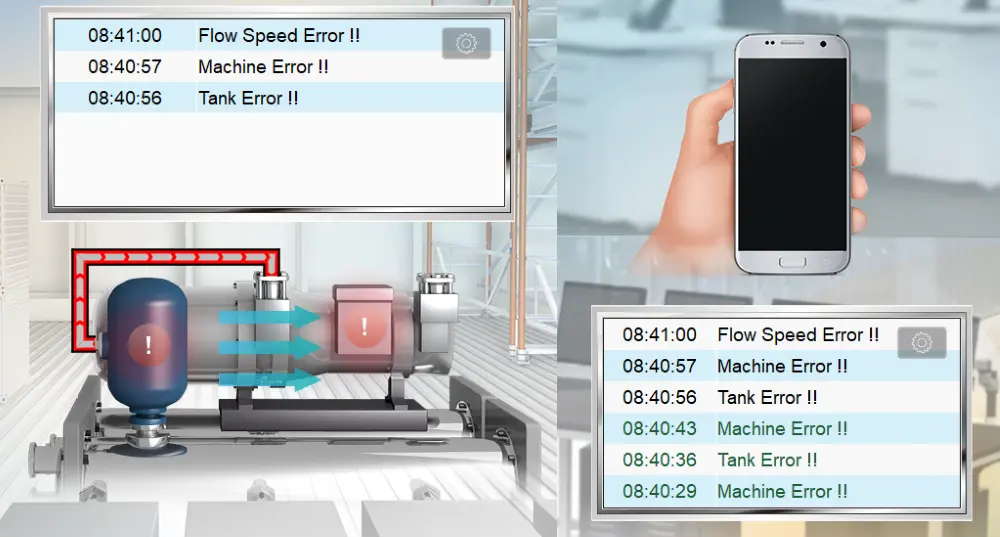

Alarm/Event Handling

- Monitor events in real-time and trigger alarms when issues occur.

- Send automated notifications to interested parties.

Remote Access

- Use internet access to review plant information and send commands to machinery from anywhere in the world.

- Monitor and control machinery from a mobile device such as a smartphone or tablet.

Security

- Prevent security breaches by providing tools to limit access and create user accounts with specific permissions.

- Encrypt outgoing transmissions.

- Collect operation logs to monitor operator activity.

History of the HMI

How did we get here? Early innovations in the field of human-machine interfaces are documented as far back as the mid-1700’s, but their form was rapidly refined during the 20th century. Modern electronics created new possibilities for what an HMI could be, with advancements in multiple sectors shaping the evolution of the HMI. Here are a few key points in the history of HMI development.

Centralized Control Rooms

In the early part of the 1900s, process control typically involved an operator directly interacting with a set of controls built into each individual machine. Over time, manufacturers separated controls and gauges from individual machines and moved them to a centralized control room, allowing operators to gain a broader understanding of operations and implement changes much more rapidly than older systems allowed. Some of the earliest control rooms of this kind had pneumatic systems installed that used regulated air pressure to remotely control machines across an entire facility. Over time, manufacturers phased out pneumatics and replaced them with electrical signals.

While these advancements established a central point of control for quick communication over moderate distances, they still tied controllers to individual machines as before. This setup meant installing a discrete controller system for each machine in the control room, requiring operators to move around different parts of the room to interact with multiple machines.

Distributed Control Systems

As digital processing evolved, computer-based algorithms started to replace the traditional discrete controller systems, paving the way for distributed control systems (DCS) to enter the field. DCS design revolutionized control system implementation by enabling the distribution of autonomous controllers throughout a system, rather than relying on a centralized controller, while still allowing operators to monitor and interact with machines from a central point.

DCS made it easier to interconnect and re-configure controls and enabled the integration of event-based control, allowing processes to respond to external factors like positioning instead of just timed sequences. This advancement led to the development of tools for alarms, electronic data logging, and fully networked systems. DCS also reduced the need for long cabling runs, and allowed for redundancy so that the failure of one controller would not impact the entire plant.

Touch Input

Developers began creating interfaces with touch input as early as the 1940s, but most industries did not widely adopt touchscreens until many years later. Over the next few decades, researchers experimented with various touch detection styles, including some that used a specialized stylus for HMI screen interaction and others that used light beams projected above the screen to register input coordinates when an object interrupted the beams. During this period, early versions of capacitive and resistive touchscreens emerged. In 1977, the first resistive touchscreen interface that could be combined with a transparent screen was developed. This breakthrough eventually made resistive touchscreens one of the most popular forms of touch input in industrial controls, and manufacturers still sell devices using resistive touch input today. Improvements in capacitive touchscreen technology would eventually lead to its widespread adoption as well, particularly after the rise of mobile devices such as smartphones and tablets.

These technological advances combined with the increased need for standardization in the industry drove interface design even further. By the turn of the millennium, HMI hardware design was beginning to solidify, with devices now closely resembling the form factor and functionality of current devices on the market today.

The Future of HMI Devices

The evolution of the HMI continues, and new technologies will guide designers towards faster, smaller, and more capable interfaces. While the future is hard to predict, promising developments in interface design and neural-networking may permanently change how human-machine interfaces are used.

Augmented Reality

The rise of Augmented Reality (AR) provides an exciting new platform for industrial control designers to explore. AR devices allow users to view feedback data and process information through a headset or mobile device, reducing the need for a dedicated HMI screen. AR devices provide an overlay across the user’s vision that will provide real-time information about the objects in their field of view and allow interaction using hand gestures.

AI Integration

The pursuit of true Artificial Intelligence (AI) has accelerated over the last decade, resulting in a host of innovations that are starting to creep into mainstream culture. By now many of us have heard of generative predictive text models such as ChatGPT, but AI promises to be more than simple text or image generation.

Advanced neural-networking models enable AI systems to actively process and analyze data, identifying gaps and inefficiencies in systems that may not be immediately obvious to humans, and then take steps to optimize those systems with minimal human interaction. Though it is too early to tell what the full impact of AI processing will be in the industrial controls sector, it will almost certainly change the face of control systems as we know them today.

Conclusion

The HMI is a pivotal element in modern control technology, bridging the gap between humans and machines. HMIs provide the tools, devices, and software that enable interactive communication, ensuring efficiency, accessibility, and ease of use. As technology evolves, the significance of HMI grows, playing a crucial role in industries ranging from manufacturing to healthcare, and constantly adapting to meet the challenges of an increasingly digital world. The future of HMI promises even more intuitive and immersive experiences, underlining its integral role in the advancement of technology and its impact on our daily lives.