Programmable Logic Controllers (PLC)

Programmable logic controllers (PLC) are electrical devices used to control

and automate industrial processes by reading digital and analog inputs such as

push buttons, limit switches, temperature or pressure sensors, and then writing to

digital or analog outputs to power devices such as LEDs, solenoids, relays, or

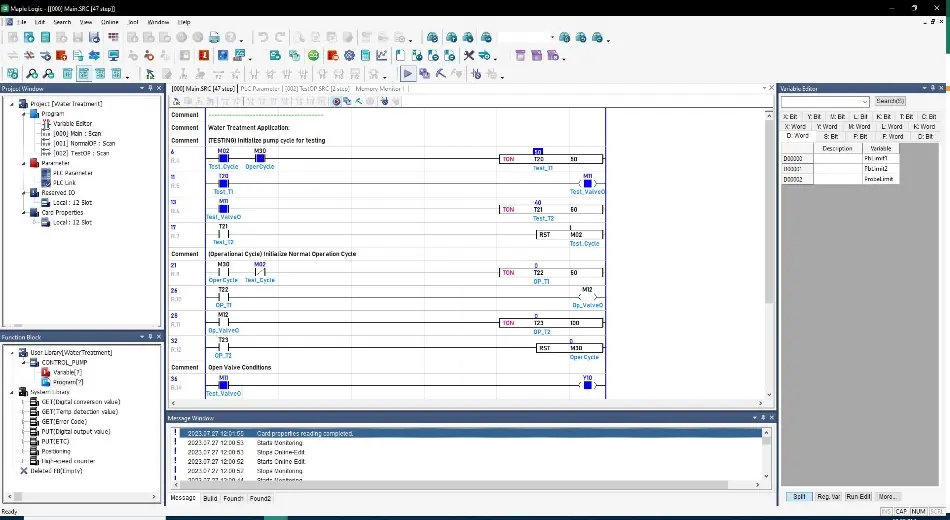

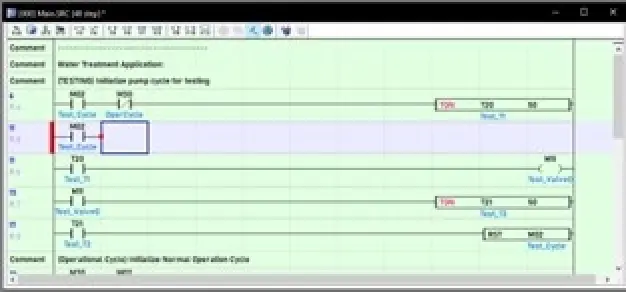

motors. PLC programming

is usually done using Ladder Logic (also known as Ladder Diagram), which is a

graphical programming language, but other IEC 61131 plc coding languages such

as Structured Text can also be used depending on the PLC.

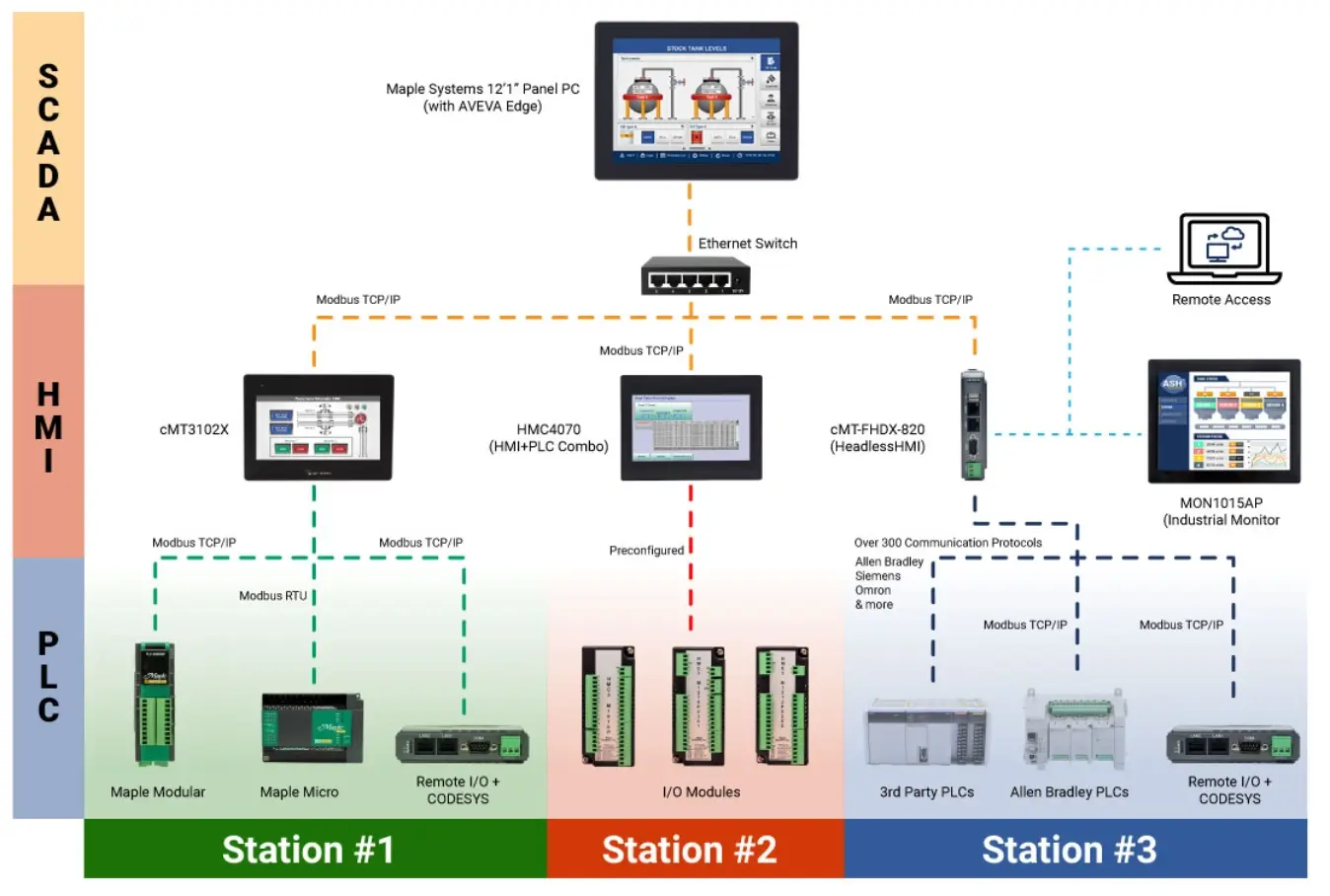

Maple Systems offers different types of PLCs to meet your system requirements, or control panel needs. Our Micro PLC is for small scale applications (Up to 36 Digital Inputs/Outputs and 2 Analog Inputs/Outputs) and our Modular PLC is expandable (up to 384 Digital/Analog Inputs/Outputs), which can be configured with any combination of modules to fit your application. Both PLC types use our free PLC programming software (MapleLogic) and easily integrate with the rest of our automation products such as our HMI/cMT products via ethernet or serial cables, using common communication protocols such as MODBUS TCP/IP or MODBUS RTU. Our PLCs easily integrate with most other industrial automation brands and SCADA system equipment if needed via common industry communication protocols.

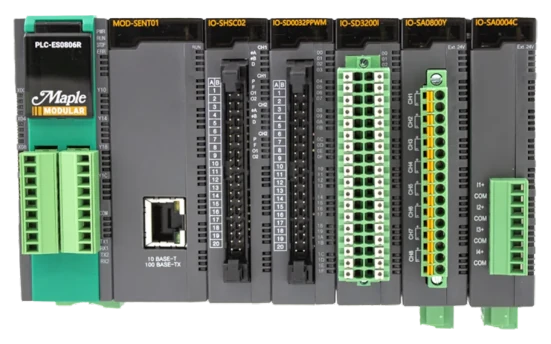

Modular PLC

Expandable PLCs with up to 11 additional I/O modules including Digital, Analog, PWM, HSC, TC and TRD Modules.

Up to 384 I/O points.

Micro PLC

All-in-one PLCs feature built-in I/O and are ideal for your small-scale projects.

Up to 36 inputs and outputs, digital and analog.

HMI + PLC

Our HMI+PLC combines the touchscreen interface capabilities of an HMI and the I/O connectivity of PLCs in just one unit.

HMI + Remote I/O + CODESYS

Designed to allow for the greatest customization with your choice of HMI, remote I/O, and the ability to execute PLC logic with a CODESYS project, this series allows you to accomplish all your needs.