Case Study

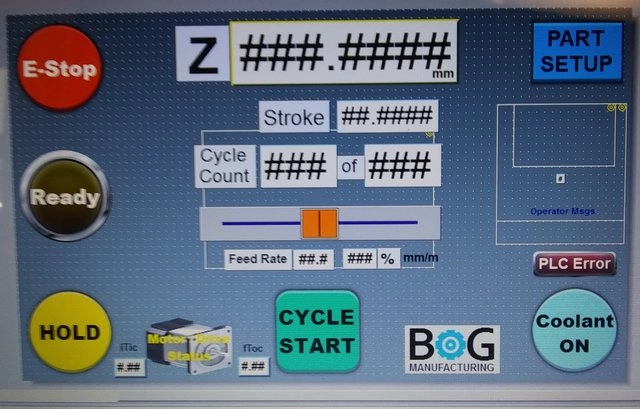

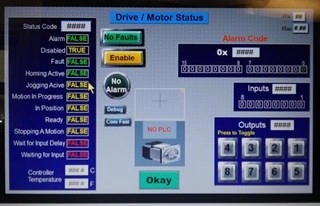

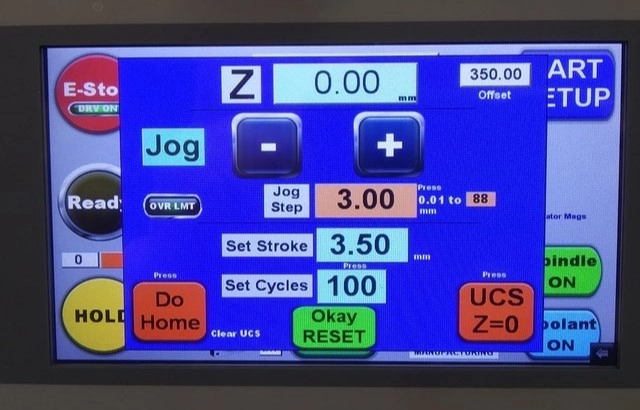

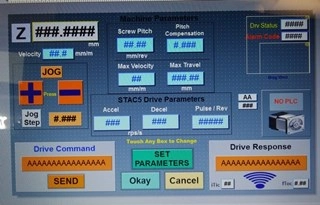

Customer shares a project representing a very complex programming application using a Maple Systems HMI

Bart Stater of CNC Solutions and Service states "To give you a little more info and an idea of the complexity of this project. It took over 2 months of intense code writing, testing and rewriting to get a functional environment that would operate in the manner desired. Then got into making it perform in a manner that was required, another several weeks."

CNC Solutions and Service

Industry: Machinery

Location: Pennsylvania, USA