Case Study

JM Controls & Electric Solutions with Maple HMIs

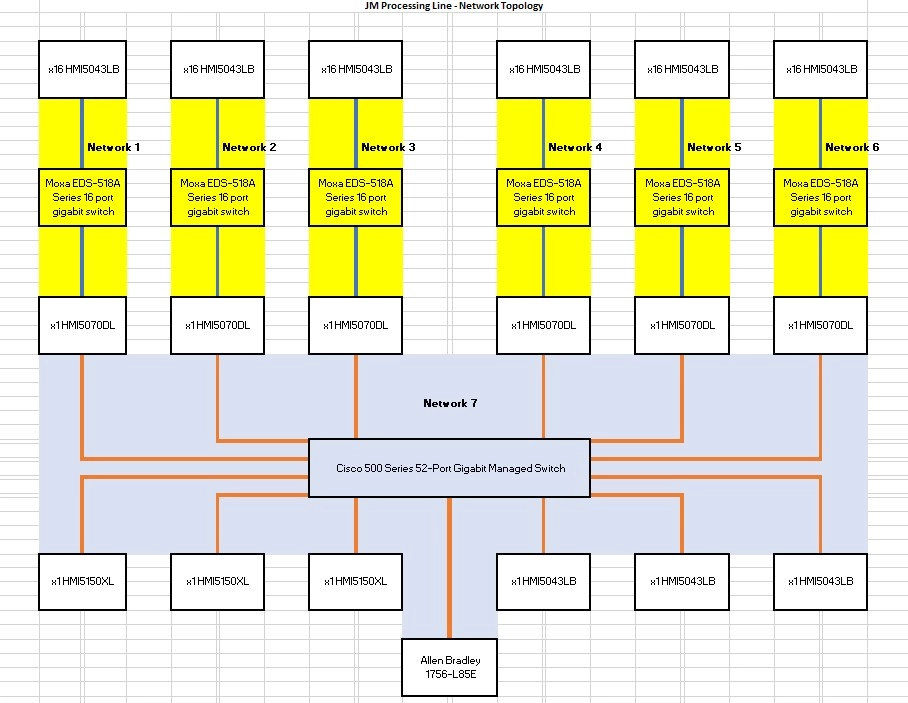

Design multi-line operator stations for control and monitoring in a large agricultural processing facility

JM Controls and Electric is a System Integrator located in Ontario Canada and they were hired to engineer, layout, design, and install a large system to sort and weight marijuana buds within a multi-station facility. There would be 5 lines and each line would have 96 4.3” HMIs, 6 7.0" HMIs, and 6 15” HMIs, communicating over ethernet via several switches to an Allen Bradley ControlLogix PLC.