Human Machine Interfaces (HMI)

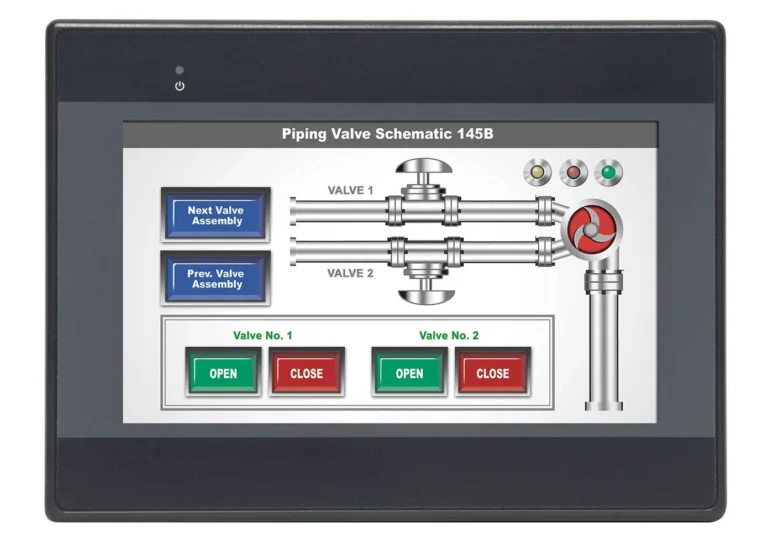

Human Machine Interfaces (HMI) make your industrial automation, data monitoring, and networking easy with our user-friendly HMIs and IIoT ready edge-devices. Our free HMI software and award-winning customer service are a couple more reasons for choosing an HMI panel that will give you the power and flexibility to streamline your processes.

Choose from touchscreen HMI display sizes of 4.3″, 7”, 9.7”, 10”, 12”, 15”, 15.6″, 21.5″ or headless HMIs, HTML5 Web HMIs and edge-gateways. Our industry-leading features include Capacitive Touchscreens, Wi-Fi, Dual Ethernet, Remote Access, Class 1 Div 2, IIoT protocols such as MQTT, Ignition, SparkPlug B , and more.

Build & Test Drive your HMI with Project Simulation

Class 1 Div 2 HMIs

Our CID2 certified HMIs are designed to keep operators and their environment safe.

HTML5 Web HMIs

Built in Chromium Browser with HTML5 standards, C1D2 Certified. No conversion or reengineering.

High-Brightness HMIs

Featuring 1000nits, this HMI solution is ideal for light intensive environments.

CODESYS + HMI + Remote I/O

Combine one of our HMIs with a coupler and remote I/O controlled using CODESYS.

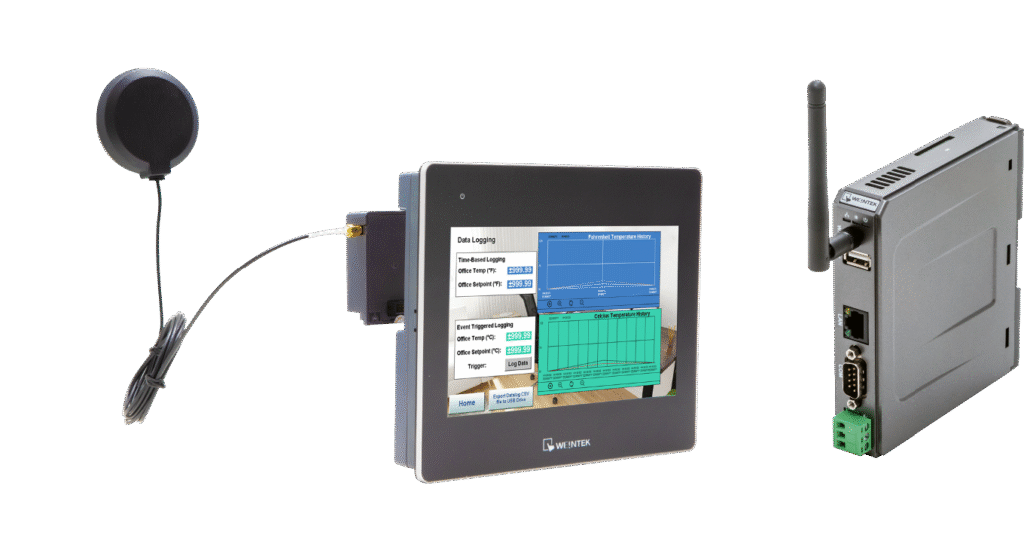

Wi-Fi Enabled HMIs

Our Wi-Fi HMIs add flexible connectivity and consolidates solutions into a single package.

Results

-

7.0″ C1D2 Rated, Rugged High Brightness, Extended-Temperature HMI

cMT3072XHTL- 1024 x 600 Resolution, 2 Ethernet Ports, 1 USB Port, 2 Serial Ports, Aluminum Enclosure

- High Brightness, 1200 nits

- Advanced features include PDF Reader, Web Streaming, Web View, and Web Browser

- Remote Access, supports MQTT JSON/AWS IoT, SQL Database and OPCUA servers

- Pair with our remote IO modules for soft PLC functionality

- UL, C1D2, CANbus, CE, RoHS, IP66, NEMA4

$939.00Quantity Discounts Available -

10.1″ WiFi Capable High Performance HMI with Built-in RFID

cMT3102Xv2R- 1024 x 600 Resolution, 2 Ethernet Ports, 1 USB Port, 2 Serial Ports, CANbus, RFID

- Built-in RFID, WiFi capable with addition of Wi-Fi Expansion Module

- Supports CODESYS with Soft PLC Functionality, Web Browser, Email, and more

- IIoT, Remote Access, MQTT, OPCUA Client/Server, SQL Database

- UL (cULus Listed), CE, RoHS, IP66, NEMA 4, ATEX

$1,219.00Quantity Discounts Available -

Advanced Headless HMI with EasyAccess 2.0 License

cMT-SVRX-822- Supports display on a tablet, laptop, smartphone, PC, cMT iV Series, and Web HMI

- Enhanced Security, Recipes, Data Logging, Barcode Scanner, Email, and more

- Remote Access, CODESYS supported, MQTT, OPCUA Client/Server, SQL Database, EasyAccess2.0 license included

- 2 Ethernet Ports, 1 USB Port, 1 Serial Port, DIN-rail Mount, Micro SD Slot

- UL, CE, RoHS

$659.00Quantity Discounts Available -

-

4.3″ Low-Cost HMI

HMI5040Bv2- 480 x 272 Resolution, 1 Ethernet Port, 1 USB Port, 1 Serial Port

- Recipes, Data Logging, Enhanced Security, Trends Graphics

- Remote Access, OPCUA Client

- CE, RoHS, IP65, NEMA 4

$345.00Quantity Discounts Available -

4.3″ Standard Touch Panel HMI

HMI5043LBv2- 480 x 272 Resolution, 1 Ethernet Port, 1 USB Port, 1 Serial Port

- Enhanced Security, Data Logging, Trends Graphics, Email Notifications

- Supports MQTT, OPCUA Client

- UL, CE, RoHS, IP65, NEMA 4

$405.00Quantity Discounts Available -

4.3″ Dual-Ethernet Advanced HMI

cMT2058XH- UNBRANDED – With a sleek blank overlay, integrating this HMI into your machine is easy

- 800 x 480 Resolution, 2 Ethernet Ports, 1 USB Port, Serial Port

- Advanced features include PDF Reader, Web Streaming, Web View, IP Camera, and CODESYS

- Remote Access, supports MQTT JSON/AWS IoT and OPCUA client

- UL, CE, RoHS, IP66, NEMA 4

$399.00Quantity Discounts Available -

-

7.0″ Class 1, Div 2 Standard HMI

HMI5070LB- 800 x 480 Resolution, 1 Ethernet Port, 1 USB Port, 2 Serial Ports

- Enhanced Security, Recipes, Data Logging, Trends Graphics, Email

- Remote Access, Supports MQTT, OPCUA Client

- UL, Class 1 Div 2, CE, RoHS, IP65, NEMA 4

$705.00Quantity Discounts Available -

7.0″ C1D2 Rated, Rugged Extended-Temperature High Performance HMI

cMT3072XHT- 1024 x 600 Resolution, 2 Ethernet Ports, 1 USB Port, 2 Serial Ports, Aluminum Enclosure

- Advanced features include PDF Reader, Web Streaming, Web View, and Web Browser

- Remote Access, supports MQTT JSON/AWS IoT, SQL Database and OPCUA servers

- Pair with our remote IO modules for soft PLC functionality

- C1D2, CANbus, CE, RoHS, IP66, NEMA4

$869.00Quantity Discounts Available -

7.0″ Cost-Effective HMI

HMI5070Bv3- 800 x 480 Resolution, 1 Ethernet Port, 1 USB Port, 1 Serial Port

- Enhanced Security, Recipes, Data Logging, Trends Graphics

- Remote Access, OPCUA Client

- CE, RoHS, IP65, NEMA 4

$450.00Quantity Discounts Available -

7.0″ High Performance HMI

cMT3072X2- 800 x 480 Resolution, 2 Ethernet Ports, 1 USB Port, 2 Serial Ports

- Advanced features include PDF Reader, Web Streaming, Web View, and Web Browser

- Remote Access, supports MQTT JSON/AWS IoT, SQL Database and OPCUA servers

- Pair with our remote IO modules for soft PLC functionality

- UL, CE, RoHS, IP66, NEMA 4

$679.00Quantity Discounts Available -

7.0″ Capacitive Touchscreen High Performance HMI

cMT3072XP- Projected Capacitive Touchscreen 1024 x 600 Resolution, 2 Ethernet Ports, 1 USB Port, 2 Serial Ports

- Advanced features include Light or Dark Themes, Web Streaming, Web View, and Web Browser

- Remote Access, supports MQTT JSON/AWS IoT, SQL Database and OPCUA servers

- Pair with our remote IO modules for soft PLC functionality

- CANBus, CE, UL, RoHS, IP66, NEMA 4

$819.00Quantity Discounts Available -

7.0″ Dual-Ethernet Advanced HMI

cMT2078Xv2- UNBRANDED – With a sleek blank overlay, integrating this HMI into your machine is easy

- 800 x 480 Resolution, 2 Ethernet Ports, 1 USB Port, 2 Serial Ports

- Advanced features include PDF Reader, Web Streaming, Web View, IP Camera, and CODESYS

- Remote Access, supports MQTT JSON/AWS IoT and OPCUA client

- UL, CE, RoHS, IP66, NEMA 4

$559.00Quantity Discounts Available

FREE User Friendly HMI Software

Free, full featured powerful HMI configuration software for our HMIs provides the flexibility to create and deploy custom control applications suited to your unique industrial process. With support for over +400 PLC controller communication protocols, EBPro enables our HMIs to seamlessly integrate with your new or existing HMI system.

Download as often as you need. No license or key needed.

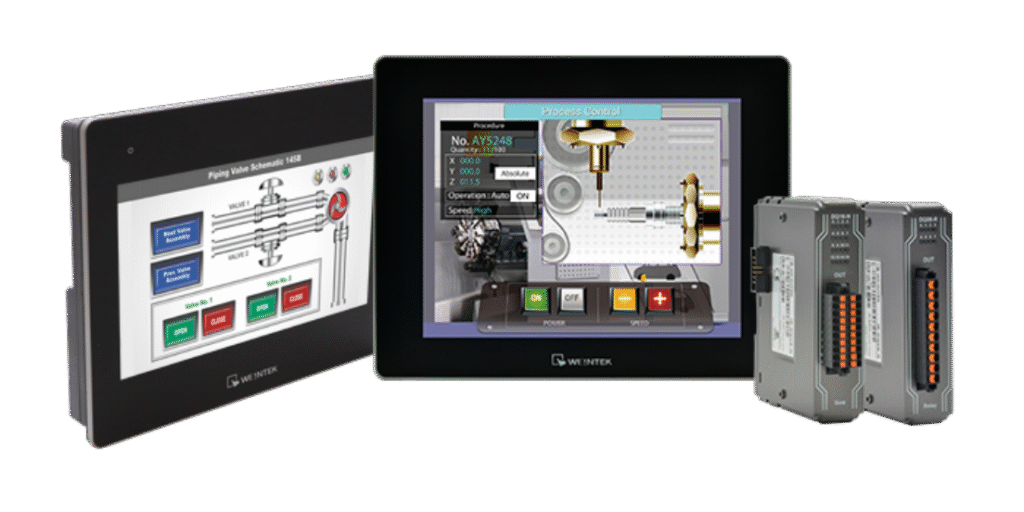

Connecting a Maple Systems HMI to a Maple Systems PLC Couldn’t Get Easier

Whether you are new to Maple Systems or are familiar with our HMIs, pairing one of our powerful HMIs with a Maple Systems PLC is easy.

Our fully functional, low-cost PLCs with built-in I/O offer you the ability to add control functionality to your project and maintain your Maple Systems HMI. These powerful units are fully functional PLCs with digital and analog I/O that support high-speed counters and PWM (pulse width modulation). Analog I/O options support several voltage and current modes as well as RTD (resistance temperature detection) and thermocouple sensors to measure temperature. Select the right PLC.

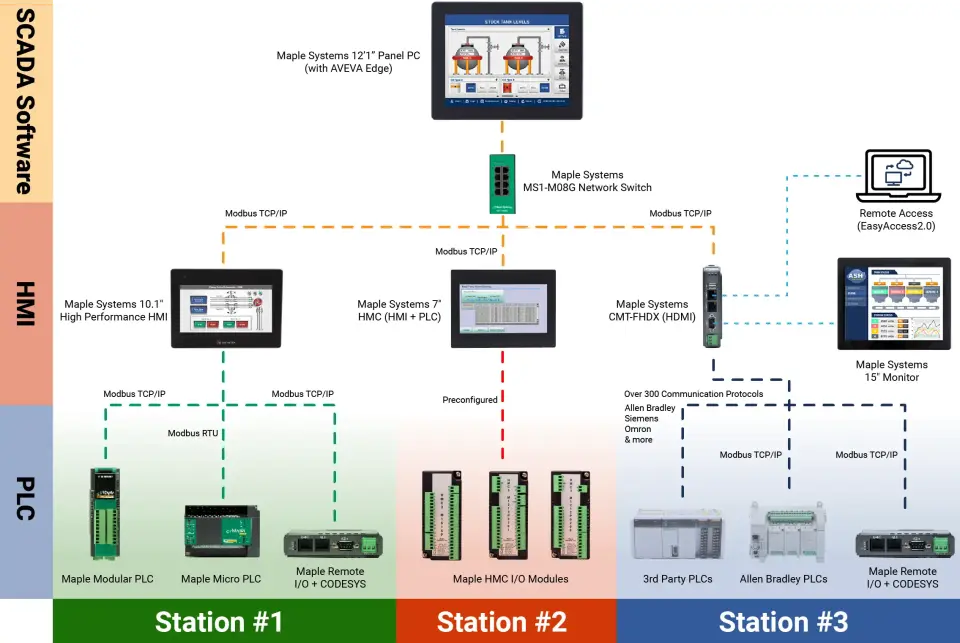

SCADA Systems and PLCs

Supervisory Control and Data Acquisition (SCADA) are systems that include various devices that allow users to monitor, control, and optimize industrial processes. SCADA systems can include different combinations of devices such as PLCs, Human Machine Interfaces (HMIs), monitors, databases, and more, to solve automation challenges.

Connect and control more devices

Industrial Network Switches

Maple Systems offers Unmanaged, Lite-Managed, and Fully Managed Industrial Network Switches for easier connection and control over your system. Coming in multiple configuration options and with an intuitive GUI ensures your network setup is perfect.

Class I, Division 2 HMIs

Maple Systems offers Class I Div 2 certified HMIs designed to keep operators and their environment safe

Any electronics being used in a potentially dangerous environment, or around flammable hazards must be Class I, Div 2 certified to prevent dangerous explosions and ensure worker safety – and we have solutions to meet this strict requirement. Our popular C1D2 HMIs are used in industries including oil and gas, mining, painting, chemical processing, pharmaceutical, food processing, and more.

Headless HMI

Our headless HMIs are perfect for systems where a fixed visual interface is not needed

These powerful HMIs are DIN rail mounted without a built-in display that allow you to monitor PLC operations, gather data, and remotely access your control system on your Apple/Android smart device. When a local display is needed and there is no time for programing, no room for complex communication wiring, our IP66/C1D2 rated Web HMIs ranging in 4.3, 7.0, or 10.1″, are the perfect solution for any environment.

HMI + Remote I/O + CODESYS

Combine the power of CODESYS with one of our CODESYS capable HMIs and Modular IO to create an innovative control solution that can tackle the most demanding applications

This unique architecture saves time, hardware cost, communication cabling, and valuable control cabinet real estate, without compromising on the CPU resources real time applications require. CODESYS provides a control solution that is one of the most complete implementations of the IEC 61131-3 standard for PLC software on the market. We offer several innovative hardware solutions serving as the perfect platform for your CODESYS HMI or PLC project. See our CODESYS Tutorials and SoftPLC Software resources.

High Brightness HMI

Create a high-brightness HMI by pairing our HDMI-enabled headless HMI with one of our high brightness industrial monitors

Our high brightness/sunlight readable projected capacitive touchscreen monitors with 1000nits are ideal for applications in Industrial Automation, Healthcare, Finance/Banking, Education, Gaming/Entertainment, Home Automation, Retail, and Transportation, and pair easily with our HDMI-enabled headless HMI. The projected capacitive technology allows use with any type of gloves.

Wi-Fi Enabled HMI

These powerful HMIs are ideal for mobile applications, remote monitoring, and device maintenance

The HMI Wi-Fi access point allows smartphones or laptops to wirelessly connect to HMI allowing monitoring and maintenance of the HMI through your connected device. The Wi-Fi access feature can be easily enabled from a browser or on the HMI. If a fixed display is required, adding our WIFI expansion module to a wifi-supported HMI creates a flexible connectivity solution consolidated into a single package.

Read our case study on how an OEM improved safety by adding Wi-Fi

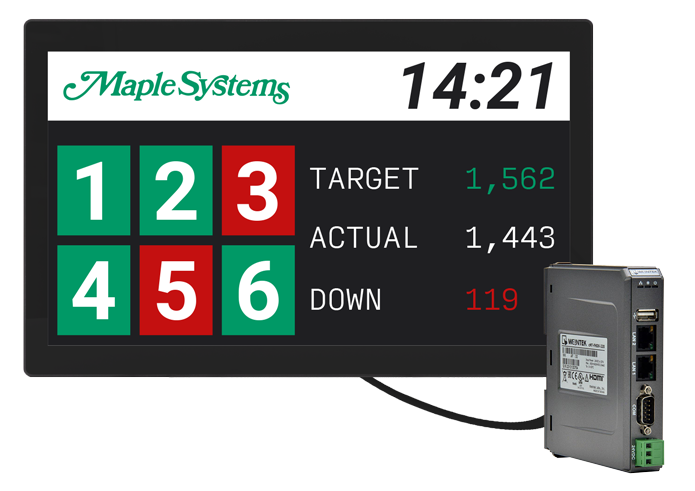

Create an Andon Station

The size of your HMI screen is no longer restricted – you can now display your real-time production data on a large, wall-mounted Status Display Station or Andon, easily visible from any plant floor location

Our HDMI-enabled unit is a powerful HMI with no display that converts any compatible TV or monitor into an Andon or Status Display Station. All HMI data and screens are displayed on an HDMI®-compatible monitor. This model divides the traditional all-in-one HMI into two, distinct parts: A data-processing unit and a separate visual display.

Customize Your HMI, HMI+PLC, or PC

Highlight your brand and differentiate your machine with a custom label

Company branding is a significant aspect of business marketing. By using custom labels on your products, you can create an identity to gain recognition from customers and potential buyers. It helps consumers recognize that the product was made by your company. Having this type of brand recognition can help your business stand out from competitors. Our Custom Labels:

- Fit Your Product Perfectly

- Offer Professional-Looking Packaging

- Strengthens Your Marketing Efforts

- Provides an Identity to Your Business