What is a SCADA System and How Does It Work?

SCADA Systems offer an opportunity for any network of devices to communicate the necessary information for more advanced monitoring, alarm detection, management, and more. This section explores the usage of SCADA systems, their common applications, and the ease of integrating devices into existing systems.

Table of Contents

SCADA Overview

Imagine a system that seamlessly integrates real-time monitoring, intelligent control, and invaluable data analytics that are capable of boosting productivity, efficiency, and overall performance. That’s the transformative capability a SCADA system brings to the table.

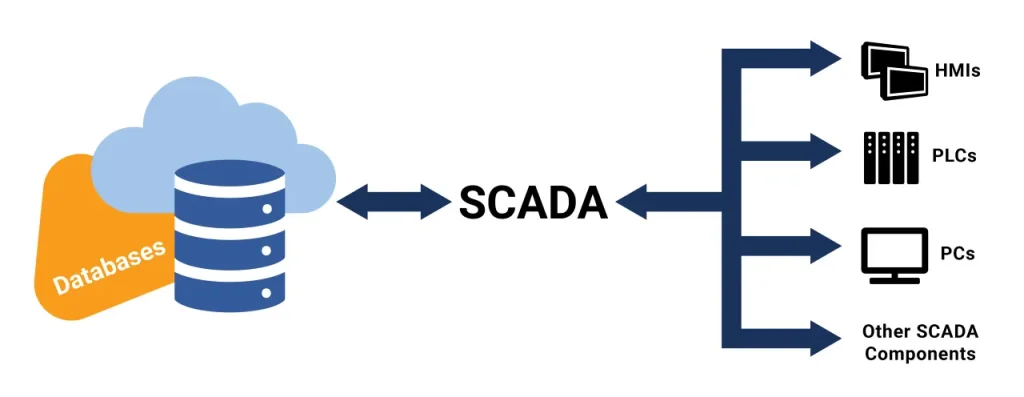

Supervisory Control and Data Acquisition (SCADA) is a control system architecture that uses computers, network data communications, human machine interfaces (HMIs), and other peripheral devices such as programmable logic controllers (PLCs) for high-level process supervisory management. While this may seem like a daunting interconnected system to wrap your brain around it’s actually fairly straightforward and as a company, we make it a priority to make this process as straightforward as possible.

Benefits of SCADA Systems Implementation

As you can imagine, SCADA systems can take on a wide range of functionality, complexity, hardware, and software solutions. Let’s delve into the functions of SCADA systems and understand how their components work together to tackle complex problems.

Below are a few examples of how sectors utilize Supervisory Control and Data Acquisition (SCADA) systems.

Oil and Gas Sector: From refineries to pipelines, SCADA systems allow operators to monitor and verify flow rates, pressures, temperatures, and other factors are all in desired ranges. Real-time monitoring allows operators to swiftly respond to discrepancies signaled by alarms, controlling processes efficiently or deploying response teams. A system that can encompass miles of production reduces the need for operators on site in favor of remote monitoring, improves efficiency by analyzing the data already recorded, and ultimately improves safety without the need to put people in harm’s way.

Plant and Factory Automation: In plants and factories SCADA systems play an important role in collecting production rates, assessing equipment health, monitoring overall performance, and notifying operators of any critical alarms. SCADA systems identify inefficiencies in setups where motors, pumps, motion sensors, and other critical assets work together yet independently. Engineers can then enhance efficiency and profitability by adjusting faulty equipment, adding necessary devices, removing redundant components, or redesigning processes. Click here to read about how we helped the Seattle Space Needle incorporate a SCADA system in their revamped project.

Water and Wastewater: Water treatment plants utilize SCADA for a variety of important processes to ensure both compliance with water regulatory standards as well as overall reliability, so the public has clean drinking water and clean waterways. Incorporating a SCADA system enables monitoring and control of pump operation, flow rates, reservoir levels, chemical dosing, and water quality. Having a system that can detect leaks, abnormal processes, and pressure changes in a complex process allows operators to act early in their intervention, rapid response, and maintenance. Click here to see the water treatment sample we have created demonstrating how simple it is to create a SCADA system utilizing one of our industrial PCs running AVEVA Edge (a SCADA software), one of our HMIs, and one of our PLCs.

Food and Beverage Sector: The food and beverage sector utilizes SCADA systems to monitor, control, and improve processes in food production and packaging. The heavily regulated food sector relies on SCADA systems for consistent cooking temperatures, mixing times, ingredient proportions, and pH levels. Predefined alarms in the system alert operators to issues like dispenser refills, temperature deviations, or equipment failures, enabling prompt corrective actions. Click here to read a case study on how one of our customers incorporated our industrial panel PC to meet their food grade standards, extreme temperature requirements, and safety standards for their dairy processing equipment.

Telecommunication Sector: Within the Telecommunication sector, SCADA systems can help track energy consumption patterns, power outages, network traffic, network performance, and even detect anomalies such as security breaches. Remote access to information via SCADA systems reduces the need for onsite operators, thereby lowering safety risks. It also aids in identifying high-demand areas, guiding decisions like building more network towers to enhance reliability and minimize network disruptions. SCADA systems play an important role in contributing to the smooth operation of telecommunication networks and services.

Transportation Sector: The transportation sector extensively utilizes SCADA systems to monitor, control, and manage various aspects of the transportation infrastructure – from the management of traffic to the management of airport operations. By collecting real-time data from sensors, which include traffic cameras, weather detection devices, and more operators can adjust traffic signals, variable message signs, and more to communicate to travelers what conditions they can expect. In railway operations, SCADA systems manage track conditions, signal systems, train schedules, and fault detection, ensuring safe and efficient public and goods transportation. Click here to see how The Golden Gate Bridge utilized our product to create a safer experience for travelers by providing them with the ability to control their connected PLC’s, providing real-time monitoring, and providing a product that can support their future growth.

Considerations when Implementing

Implementing a SCADA system involves key considerations for effective and successful application. Thorough planning is crucial to avoid common issues and tailor the system to specific needs and requirements. Below are a few considerations to consider.

Requirements of the System

The project’s scope, integration needs, and monitoring objectives must be clear to determine the required equipment (hardware and software), processes, and network infrastructure for the SCADA system.

Data Acquisition and Communication

It’s important to plan out how your devices will communicate with each other. If you find that your devices don’t have any matching communication methods then you may have to purchase another compatible device or use a gateway – a hardware device or software that translates one communication method to another allowing two devices to talk to each other. As for data acquisition, determine what method you want to collect your data. Consider how your SCADA software handles sensor data. Does it manage everything, or does it send information to a data server like MySQL for processing?

Security and Authentication

Security is vital for a SCADA system, especially if it’s remotely accessible. Implementing firewalls, encryption, authentication, and access control is essential to protect critical data and infrastructure. By determining the measures of security now, you can protect yourself from data breaches, cyber-attacks, and more in the future. To learn more about the different aspects of creating a SCADA system read our SCADA and HMI Guide.

How to Implement SCADA Systems

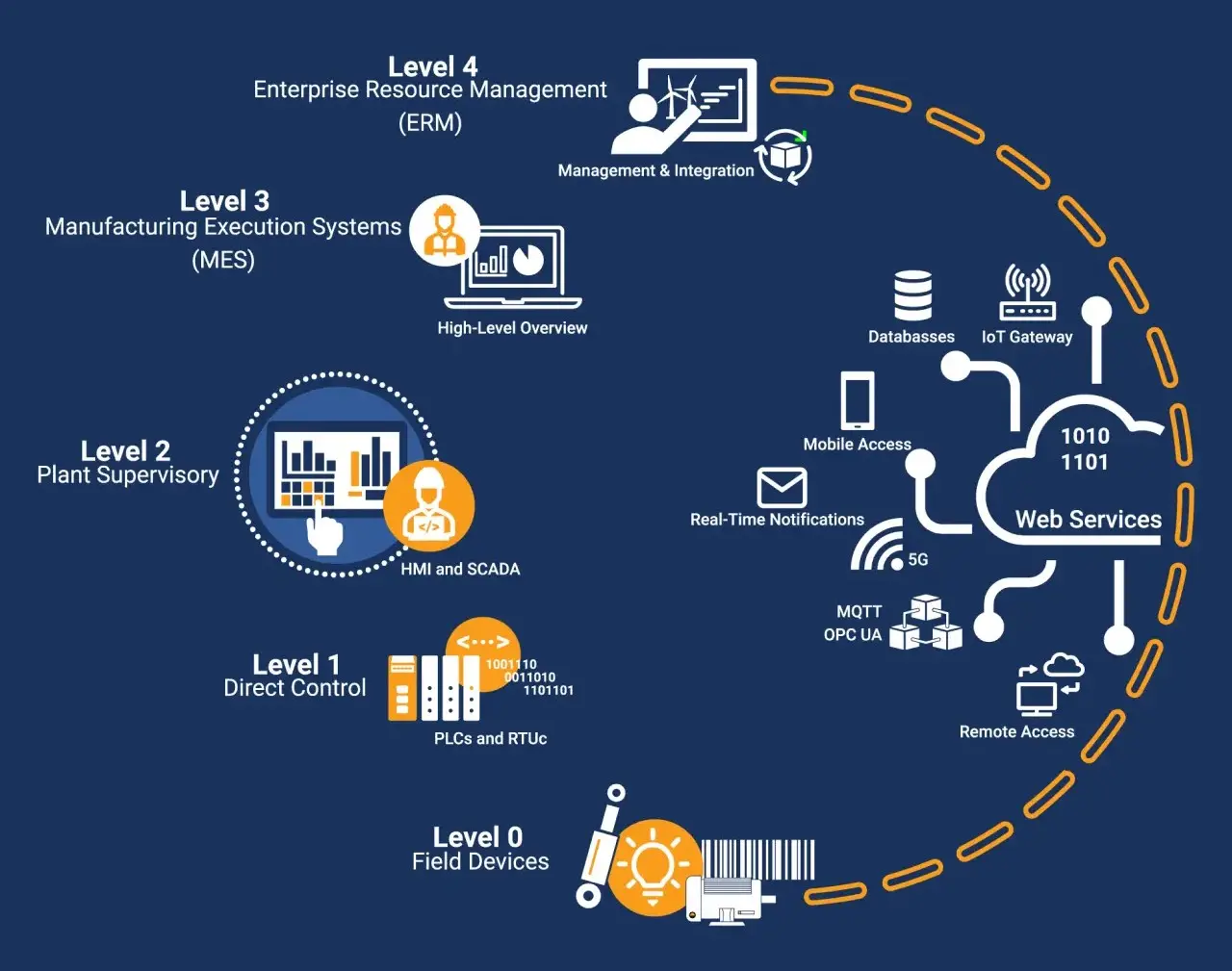

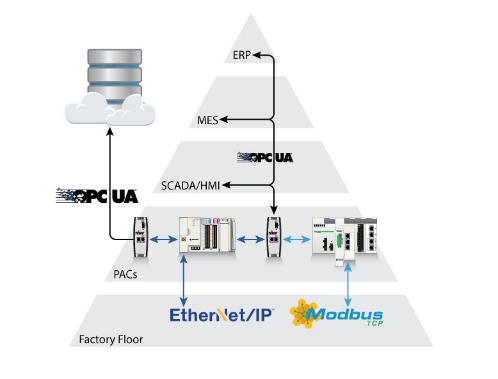

Many models of a SCADA system may vary from resource to resource. However, there are generally three levels (0-2) within a SCADA system, but there are two additional levels within the whole production framework that we will touch on. Each level of the SCADA system performs specific tasks and communicates with other levels for efficient monitoring and control of processes.

Below are the different levels of the SCADA Framework and their roles.

The Field level or sometimes called the Process Level includes physical devices and sensors. These instruments include temperature sensors, pressure sensors, meters, valves, motors, and other devices that measure and can control different parameters of a process. For example, information such as temperature of a liquid gets sent to the direct control level (Level 1) and if it’s determined the temperature is too low, then the control device will trigger a heating coil to come online to start the heating process.

The Direct Control level comprises of PLCs (Programmable Logic Controllers) or RTUs (Remote Terminal Units) which are programmed to follow rules and instructions. In the heating example, in the previous level, the PLC triggered the heating coil to turn on because the temperature went below a predetermined value that the programmer set. These controllers are therefore responsible for the control and management of the field devices – and is the intermediary between them and the supervisory level.

The Plant Supervisory level is the highest level of the SCADA Framework. Operators can visually monitor the system with a Human Machine Interface (HMI) or other devices such as a PC monitor that is running SCADA Software. The Supervisory level comprises of both the control center and the software application that oversees the entire operation and where real-time data, graphical representations, alarms, and more can be monitored and controlled by sending and receiving directions to the direct control devices in level 1. This level enables operators to create reports, respond to major events, and make informed decisions on everyday operations.

[Optional] In some cases, additional levels are required to be incorporated into the production framework to ensure better optimization and smoother operation. The Manufacturing Execution System (MES) level integrates the SCADA system with additional systems to collect and monitor material management, work progress, performance, and other critical factors. The accumulated data allows factory leaders to see how well production is going and what possible changes can be made to optimize the system.

[Optional] Similarly to Level 3, the Enterprise Resource Planning (ERP) level incorporates critical information from previous levels of production but also incorporates scheduling and timelines. While the MES level is usually incorporated on the production floor and works in real-time, ERP works with other business and marketing applications to provide quantitative analysis reports of the overall performance of the system over an hourly, weekly, or quarterly basis.

While this is a general hierarchy of what a SCADA framework looks like – every application is different and requires deferring architectures, so use this model more as a guide than the rule.

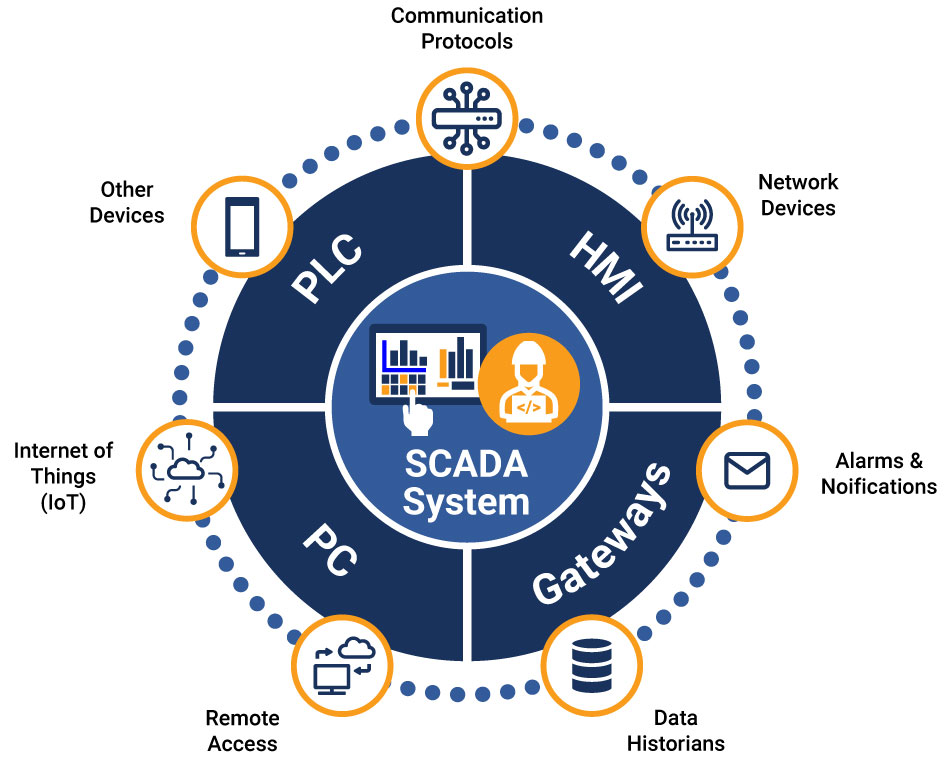

Components of SCADA Systems

There are many components a SCADA system can utilize to accomplish a project’s desired results. These implementations rely solely on the project’s requirements and objectives. Below you can find the different components a SCADA system may utilize, hover over the bubble to expand the sections:

As you can imagine this can take on a wide range of functionality, complexity, hardware, and software solutions. Within this article, you will learn about what makes SCADA amazing and how Maple Systems can facilitate all your needs. For more information on component click on the drop down menu below to expand the detail component view.

Programmable Logic Controller (PLC)

PLCs can be considered the brains of the systems they control because they acquire and translate signals from field devices and with the help of logic, that has been preprogrammed onto the PLC, execute the necessary steps to accomplish a given task.

For example, if a high-pressure reading is detected by the PLC from one of its input sensors, the PLC can be programmed to set off an alarm and open a pressure valve to reduce the pressure in response to the pressure reading being outside the predefined allowable values. PLCs are widely used because they are reliable, flexible, and easy to program allowing them to continuously automate processes, monitor systems, and ensure operator safety. PLCs are most commonly programmed using ladder logic, a visual programming language that resembles circuit diagrams, however, other programming languages are used such as Function Block Diagram (FBD), Sequential Function Charts (SFC), Structured Text (ST), and Instructional List (IL).

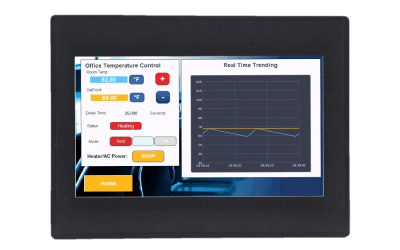

Human Machine Interface (HMI)

With the ability to connect to many devices such as PLCs and other network devices, HMIs provide a visual interface that allows supervisory control over small to medium systems. HMIs are typically touch panels or computer screens that include advanced features such as IIoT functionality (MQTT, SQL Databases, OPC UA, etc.), multi-tasking ability, capability to remote access the unit with a Virtual Network Computing (VNC) program, and more useful tools. HMIs allow operators to observe and command dedicated sections of a plant and transmit that information to a larger SCADA system which then can function as the central control. To learn more about HMIs and how they are incorporated in a SCADA system, check out our resources listed below.

HMI Design Guide

A guide to the functionality, advancements, and role HMIs have in IIoT operations. Learn how HMIs can be a great asset to any automation plant and what functionality may be available in the future.

Industrial Panel PC

Are designed to work in hazardous environments, run demanding software, provide flexible programming, and/or allow for decentralized computing with screen-less options. These PCs can handle the computing power required of SCADA systems, the fanless designs make them more rugged, and the customization of a given PC (choice of operating system, software that is included, etc.) allows for specification within an automation system.

In addition, with many automation challenges relating to the environment equipment is installed, if the equipment is not built to withstand harsh conditions, then additional resources need to be allocated to resolve these problems. In some situations, equipment may need to be shielded from its surroundings – whereas if an industrial panel PC was installed it would be able to handle these conditions safely. Being able to incorporate a SCADA system, either locally or through the cloud, reliably created the foundation of a successful and smooth automation process.

Gateways

Gateways are network devices that allow for communication between two or more devices that may not have the available protocols to talk to each other. They are implemented in pre-existing systems to aid in the transmission of data packages from one destination to another allowing for legacy devices to communicate with updated systems.

These gateways are typically hardware devices that are implemented in the field, however, gateway software is also available for download, as an example our HMI software has the capability of being a gateway between two devices.

Communication Protocols

Communication Protocols are sets of rules used to describe how information, or data, is transmitted from one location to another. For example, one of the most used IoT communication protocols is WiFi, which is used to transmit information wirelessly on a local network. In automation there are hundreds of communication protocols created by vendors to solve different problems within specific industry sectors – that means depending on the application and the devices used, the available communication protocols will be different.

SCADA software typically has a vast list of protocols that allow users to connect all their devices without needing a gateway device. The most common communication protocols across all sectors are MODBUS TCP/IP or Serial, EtherNet/IP, Profinet, and OPC Unified Architecture (OPC UA).

Network Devices

Network devices are any hardware that is used to connect devices on the network. These can be used to amplify a signal, used to increase the amount of transmission points to the network or create another barrier of security. These network devices can include repeaters, switches, gateways, and more. A SCADA system may employ a router to get access to devices on the network or even cloud services such as a Database.

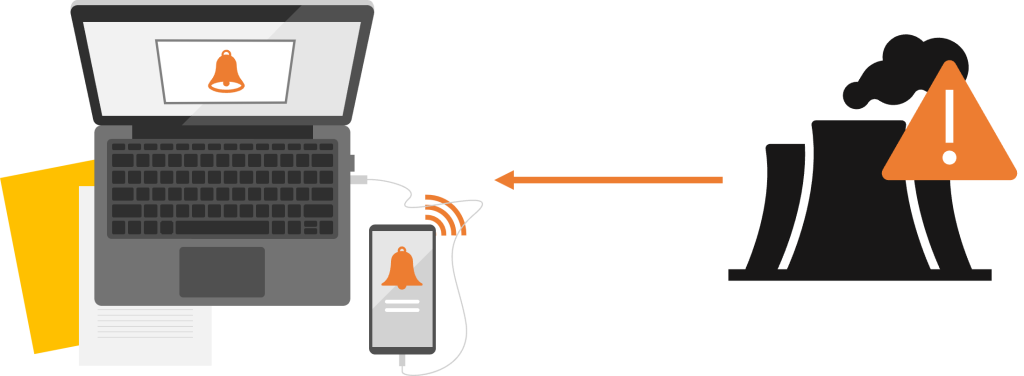

Alarms and Notifications

Alarms and notifications have a crucial role in SCADA systems by serving as early warning systems, detecting faults and diagnosing them, and being the catalyst for improving operational efficiency. Because SCADA systems monitor the entire system, when the unexpected happens and alarms are set off, operators can analyze and identify in real-time what the potential failures are within the system.

With the ability to get notifications of critical events in real-time, to an operator’s phone for example, the deployment of maintenance crews can be quickly initiated thereby reducing idle time, the need for factory floor personnel, and emergency response time in the event of a catastrophic failure.

Data Historians

Data Historians are databases that retain long-term data storage that can be used for analyses, general monitoring, and distribution of information where it is needed. The data collected is dependent on the operational need of the factor, however common information that is collected are sensor readings, data processes, and alarms.

SCADA systems can be considered the middleman between device information and databases, they send critical information to the database as well as use the stored information for analysis.

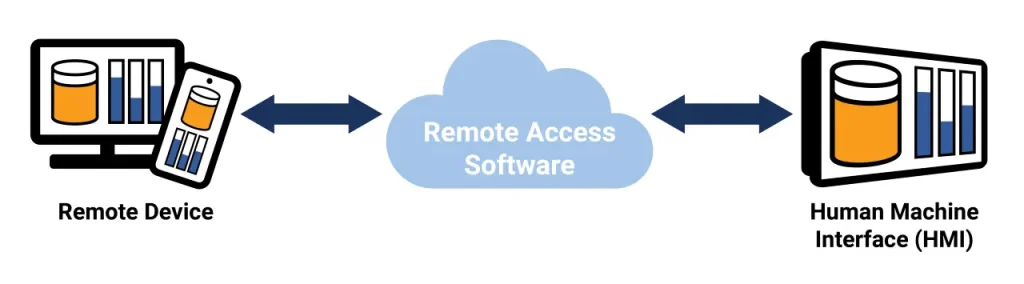

Remote Access

Remote Access allows systems to be accessible from any location with a tablet, PC, or even phone; eliminating the need for on-site workers and reducing costs associated with maintenance. Additionally with the ability to monitor and control a system from anywhere in the world, responses to emergencies can be quicker, safer, and even preventable.

Going even further, remote access allows for centralized control by allowing operators to monitor multiple SCADA systems at any given time. However, it is important to implement strong security measures to protect critical infrastructure from cyber-attacks and other threats. Click here to learn more about how we support remote access.

Internet of Things (IoT)

The Internet of Things is the collection of devices that allow data to be shared from the factory floor to a server, enhancing greater network efficiency and data sharing. IoT is not necessarily the devices that are used, but rather a description of how these devices communicate, typically over the internet, and exchange information.

These physical devices are sometimes known as “smart” devices and can be anything from a thermostat to a vehicle, or even complex industrial machinery. By allowing these devices to seamlessly communicate with each other, IoT enhances such capabilities, in a SCADA system, as advanced analytics, overall scalability, and remote monitoring and control.

Other Devices

SCADA solutions come in all forms and sizes and the devices that are employed can vary greatly between each application, size of a system, and industry. A few systems or devices we have not mentioned but may be used in a SCADA system are redundancy systems, dedicated alarm panels, virtual machines, remote sensors, and surveillance cameras. When additional devices are integrated into a system, they possess the capability to tackle the specific challenges that system faces.

How Maple Systems Can Support You in Your SCADA Journey

Maple Systems offers all the components you need to create your own unique level of supervisory data acquisition and control, from the simplest stand-alone machine to sophisticated multi-device networked production line(s), all the way to enterprise-level operations an IIoT functionalities leveraging cloud connectivity.

Log data from your devices to aid in reporting, to gain efficiencies, reduce downtime, and plan for routine maintenance. Add additional IIoT functionality like MQTT, OPC UA, Ignition, SQL database integration, and more. Our products can help you standardize communications between devices, gluing different systems together for one source to your SCADA system. No need to redesign your entire application.

Keep the components that are already working for you, just add Maple Systems components to grow your abilities to supervise, control, and acquire data.

Our industrial Panel PC Lines are designed to meet all your automation challenges – from being able to operate in extreme environments to allowing you to configure your PC to your specifications. These PCs give you the freedom to choose how you build out your system without compromising on performance or safety.

Class 1 Div 2 PCs

Designed for hazardous environments – perfect for oil, gas, and more applications.

High Brightness Industrial PCs

Designed to be readable in light intensive environments – perfect for outdoor applications.

Embedded Industrial Box PCs

Designed to be used in applications that don’t require a fixed display – a monitor can be connected if needed.

Our HMI Product lines are designed to fulfill all your automation needs. With over 300 communication protocols our HMIs can connect to your pre-existing system while allowing you to expand your network with additional IIoT protocols, user friendly software, and more.

Class 1 Div 2 HMIs

Designed for hazardous environments – perfect for oil, gas, and more applications.

Headless HMIs

Designed to monitor PLC operations, collect data, and more without the need for a physical monitor – these HMIs can be accessed remotely.

HMI + Remote I/O + CODESYS

Designed to allow for the greatest customization with your choice of HMI, remote I/O, and the ability to execute PLC logic with a CODESYS project.

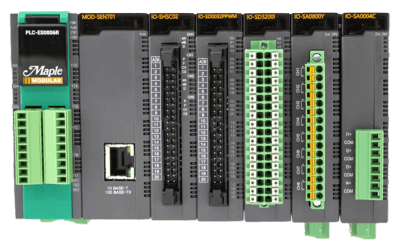

Our PLCs allow for ease of monitoring, controlling, and transmitting data of field devices with the help of our free PLC programming software: MapleLogic. Maple Systems PLCs can be added to pre-existing, or new, systems effortlessly with our device’s native configuration settings allowing for seamless integration.

Maple Micro

Standalone compact unit that can accomplish small to medium applications or be implemented into a larger project.

Maple Modular

Compact and expandable unit that can accomplish your larger applications. Expandable units include High-Speed Counters (HSC), Pulse Width Modulation (PWM), and Analog Temperature functionality.

PLC Product Line

Learn more about the features and specifications of our PLC product line.

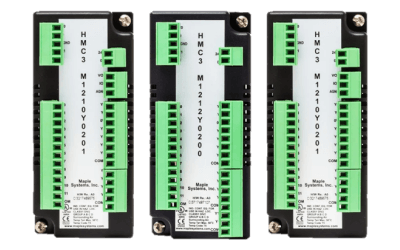

Our HMC product line combines the interface capabilities of traditional HMIs and the I/O abilities of PLCs in just one affordable unit. Customize your project to meet your specific needs by choosing between multiple screen sizes and I/O modules while only using one easy to use software.

HMI + PLC (HMC) Models

Designed to be a compact all in one unit. Our HMC units offer a range of screen sizes, module expansion slots, and functionality such as graphical trends, data logging, and more.

Expansion I/O Modules

Compact expansion I/O modules that easily attach to the back of the HMC model. Select between a wide range of digital and analog I/O configurations.

HMI + PLC (HMC) Product Line

Learn more about the features, specifications, and our all-in-one software for our HMC product line.

We make it a priority to have our products work with your existing system by providing all the necessary software, resources, and guides to meet you where you are at. We also provide free Technical Support based in the U.S., ensuring you have all the resources you need to create your unique industrial solution. Call our Technical Support Team at (425) 745-3229 available Monday-Friday from 6:00 AM to 4:30 PST.

Our HMI‘s make it simple to communicate with your current equipment. With over 300 communication protocols, our HMI’s make it implementation into your system easy. Check out our controller information sheet to see which communication protocols we support, and make sure to look at our dedicated Allen Bradley Controllers page for Allen Bradley devices.

If you are familiar with CODESYS, a third party software that allows you to program controller applications, our select HMIs allow you to run your CODESYS program with your choice of controller, or our Remote I/O products, with ease. Our CODESYS quick-start guide on our Manual & Guides page gives you a easy guide to follow to set up your devices.

AVEVA Edge, formally known as Web Studio, is a SCADA software that allows you to accomplish all your control and monitoring tasks. The award-winning software has all the tools you need to create your one-of-a-kind solution. To learn more about our partnership with AVEVA Edge check out the AVEVA Edge Software page.

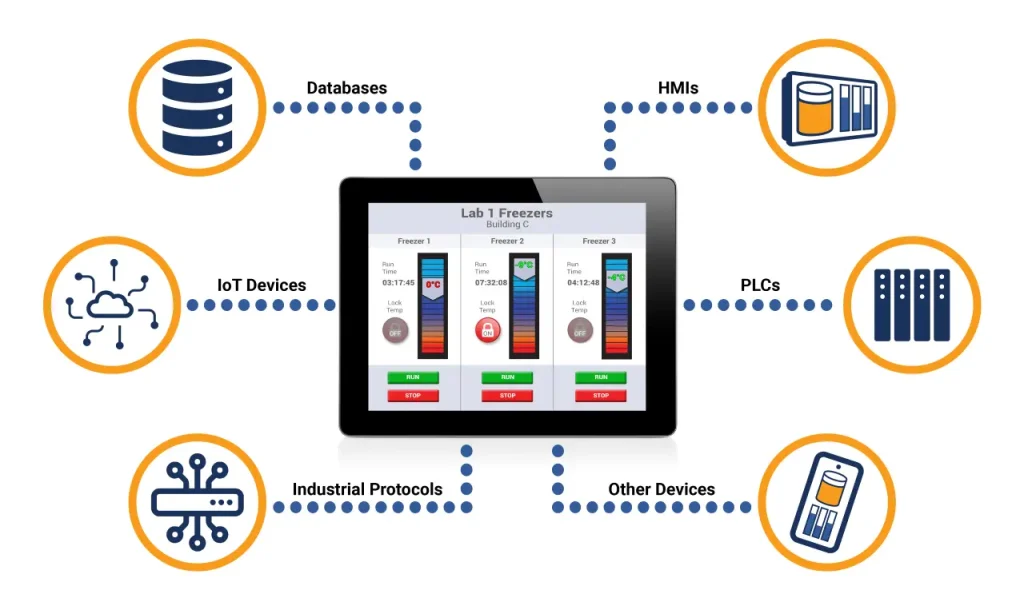

Water Treatment Application

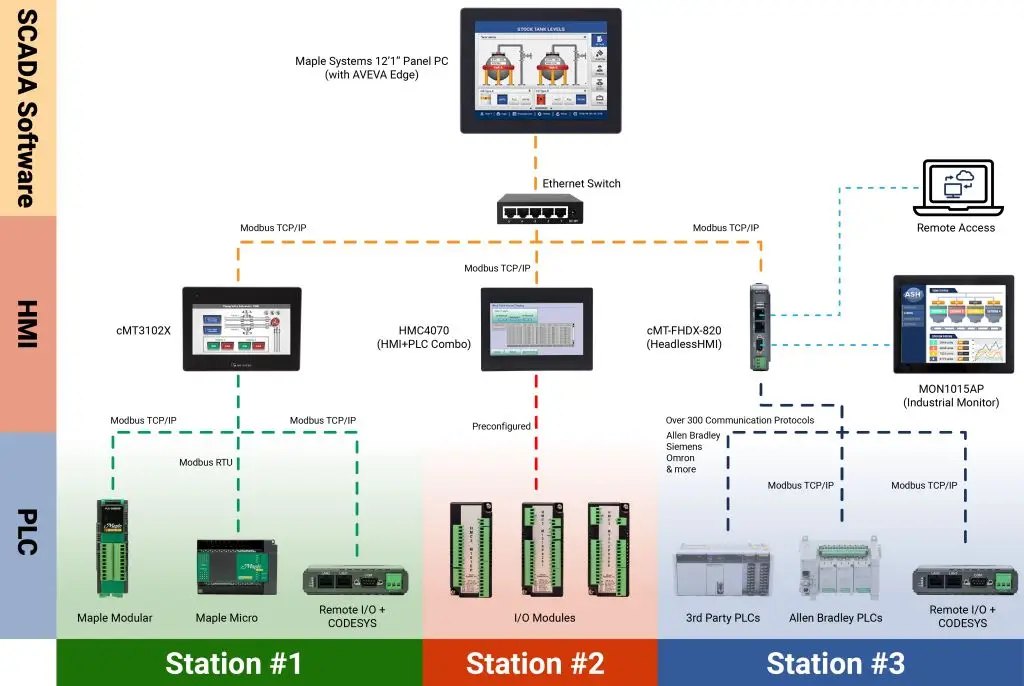

Water Treatment is the process of treating and purifying water for safe consumption and use by end-users. In the this process, water from sources like reservoirs undergoes physical and chemical procedures to remove debris, pathogens, and contaminants, ensuring it meets local standards. In the below graphic, we can see that the SCADA system plays an integral role in communicating with three water treatment stations. With all stations physically working apart, operators can monitor water quality, equipment statuses, and other events through a panel PC running SCADA software.

The Diagram also illustrates how you can use our products for all your SCADA needs. The diagram illustrates how our products cater to all your SCADA needs. For an HMI that communicates seamlessly with our PLCs or Remote I/O’s, as depicted in station 1, we’ve got you covered. Seeking a simple HMI and PLC solution without communication compatibility concerns? Our HMC (HMI + PLC Combo) line, featured in station 2, is the perfect fit. Even if you’re using a different PLC brand, such as Allen Bradley, compatibility isn’t a problem. Our HMI software (EBPro) supports over 300 communication protocols, enabling easy connection to your existing devices. Furthermore, station 3 shows how our headless units offer remote monitoring and the option to connect your own screen, ideal if you don’t require a built-in screen on your HMI. In addition, station 3 demonstrates if you don’t require a screen on your HMI, our headless units allow for remote monitoring and the ability to plug in your own screen if needed.

Software for SCADA Systems

SCADA systems encompass a diverse range of devices, each requiring tailored software to meet their specific needs and ensure the seamless and efficient operation of the system. To learn more about the individual software applications used in the water treatment application click on the software links below.

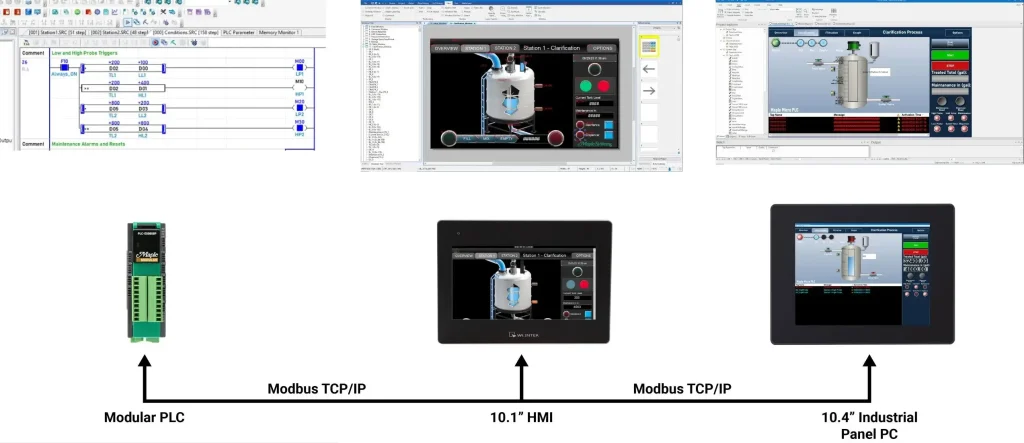

Following the water treatment schematic, we can create a simple SCADA project to control and monitor Station 1. This station’s purpose is to clarify raw water by pumping it into a tank, adding the necessary chemicals for treatment, and rapidly mixing the solution until sending the treated water to the next station for filtration. Key project considerations include the number and type of field devices, available communication protocols, and the desired interaction with the SCADA system.

For example, the PLC we have chosen is the Maple Modular, this allows us to add I/O modules for our current field device needs and gives us the option to add more in the event of future growth. The HMI chosen is a 10.1″ unit for its IP66 rating, screen size, and IoT functionality, while the PC is a 10.4″ industrial panel PC compatible with any SCADA software and suitable for control room mounting.

We then connected each device via ethernet using Modbus TCP/IP protocol for communication. With all devices programmed (MapleLogic for our PLC, EBPro for our HMI, and AVEVA Edge for our PC), our SCADA system efficiently monitors water treatment, process times, and necessary actions for alarms like dispenser refills.

If you are curious about how our products work, check out our support page where you can find tutorials, sample projects, and more.