Your cart is currently empty!

AVEVA™ Edge

Award-winning AVEVA™ Edge is a powerful HMI/SCADA software package that enables you to create custom industrial control applications for your unique industry. With easy-to-use commands/tool bars and a Microsoft Windows® environment, AVEVA™ Edge’s feature-rich application puts you in the driver’s seat of creating your industrial process.

Contact Sales for pricing options.

Choosing the ideal AVEVA™ Edge runtime edition solution for your project

You can use the same development environment (AVEVA Edge STUDIO), on Windows, to create all projects and run each project with the runtime edition most suitable for the technical and commercial constraints of each platform:

- AVEVA Edge SCADA for full version, all the bells and whistles, SCADA projects running on Windows-based stations

- AVEVA Edge Embedded HMI, less bandwidth, not as many bells and whistles as SCADA, but for full featured HMIs running on Industrial Panel PCs with Windows IoT Enterprise LTSB/LTSC

- AVEVA Edge IoT View for IoT edge devices or local HMI solutions using Linux or non-Windows OS

For help choosing which Runtime License version/platform (SCADA, Embedded HMI, IoT View) is best for your application, refer to this reference guide for more information on what runtimes are compatible with different operating systems and system requirements. This guide is valid for AVEVA Edge 2023.

Explore the full list of prices for AVEVA™ Edge to discover the cost details and make informed decisions for your industrial control applications needs.

NOTE: For AVEVA Edge or WebStudio Upgrade options, please contact sales@maplesystems.com or call us at 425.745.3229

Results

-

AVEVA™ Edge HMI/SCADA – Development + Runtime license, 1,500 tags, 1 Thin Client – New License

EDGEDR-01-N-23- HMI/SCADA Full Version

- 1 Development License, 1 Runtime License Included

- 1,500 Tags, 1 Thin Client (Runtime only)

- Softkey Only, Hardkey Sold Separately

$3,855.00Quantity Discounts Available -

AVEVA™ Edge HMI/SCADA – Development license, 1,500 tags, 1 Thin Client – New license

EDGED-01-N-23- HMI/SCADA Full Version

- Development Only License

- 1,500 Tags, 1 Thin Client

- Softkey Only, Hardkey Sold Separately

$1,435.00Quantity Discounts Available -

AVEVA™ Edge HMI/SCADA – Runtime license, 1,500 tags, 1 Thin Client – New License

EDGER-01-N-23- HMI/SCADA Full Version

- 1 Runtime License Included

- 1,500 Tags, 1 Thin Client

- Softkey Only, Hardkey Sold Separately

$2,385.00Quantity Discounts Available -

AVEVA™ Edge HMI/SCADA – Development + Runtime license, 4,000 tags, 1 Thin Client – New License

EDGEDR-04-N-23- HMI/SCADA Full Version

- 1 Development License, 1 Runtime License Included

- 4,000 Tags, 1 Thin Client (Runtime only)

- Softkey Only, Hardkey Sold Separately

$6,790.00Quantity Discounts Available -

AVEVA™ Edge HMI/SCADA – Development + Runtime license, 16,000 tags, 1 Thin Client – New License

EDGEDR-16-N-23- HMI/SCADA Full Version

- 1 Development License, 1 Runtime License Included

- 16,000 Tags, 1 Thin Client (Runtime only)

- Softkey Only, Hardkey Sold Separately

$6,850.00Quantity Discounts Available -

AVEVA™ Edge HMI/SCADA – Development + Runtime license, 32,000 tags, 1 Thin Client – New License

EDGEDR-32-N-23- HMI/SCADA Full Version

- 1 Development License, 1 Runtime License Included

- 32,000 Tags, 1 Thin Client (Runtime only)

- Softkey Only, Hardkey Sold Separately

$7,925.00Quantity Discounts Available -

AVEVA™ Edge HMI/SCADA – Development + Runtime license, 64,000 tags, 1 Thin Client – New License

EDGEDR-64-N-23- HMI/SCADA Full Version

- 1 Development License, 1 Runtime License Included

- 64,000 Tags, 1 Thin Client (Runtime only)

- Softkey Only, Hardkey Sold Separately

$10,500.00Quantity Discounts Available -

AVEVA™ Edge HMI/SCADA – Development license, 4,000 tags, 1 Thin Client – New license

EDGED-04-N-23- HMI/SCADA Full Version

- Development Only License

- 4,000 Tags, 1 Thin Client

- Softkey Only, Hardkey Sold Separately

$2,850.00Quantity Discounts Available -

AVEVA™ Edge HMI/SCADA – Development license, 16,000 tags, 1 Thin Client – New license

EDGED-16-N-23- HMI/SCADA Full Version

- Development Only License

- 16,000 Tags, 1 Thin Client

- Softkey Only, Hardkey Sold Separately

$2,890.00Quantity Discounts Available -

AVEVA™ Edge HMI/SCADA – Development license, 32,000 tags, 1 Thin Client – New license

EDGED-32-N-23- HMI/SCADA Full Version

- Development Only License

- 32,000 Tags, 1 Thin Client

- Softkey Only, Hardkey Sold Separately

$3,330.00Quantity Discounts Available -

AVEVA™ Edge HMI/SCADA – Development license, 64,000 tags, 1 Thin Client – New license

EDGED-64-N-23- HMI/SCADA Full Version

- Development Only License

- 64,000 Tags, 1 Thin Client

- Softkey Only, Hardkey Sold Separately

$4,275.00Quantity Discounts Available -

AVEVA™ Edge HMI/SCADA – Runtime license, 150 tags, 1 Thin Client – New Update

EDGER-15-N-23- HMI/SCADA Full Version

- 1 Runtime License Included

- 150 Tags, 1 Thin Client

- Softkey Only, Hardkey Sold Separately

$755.00Quantity Discounts Available

Supported Hardware

Industrial PCs are designed to resolve your toughest automation challenges in manufacturing, processing, and fabrication environments. All our Industrial PCs are full-strength industrial computers and can operate any Windows® Software, or powerful SCADA software such as Aveva Edge®. There is a lot to consider when it comes to choosing the right Industrial PC, and the right solution for you will depend largely on your unique situation. It is important to fully understand how each of these factors will impact your timeline, budget, and hardware options.

In addition to our powerful Industrial PCs and Panel PCs, Maple Systems offers a full line of industrial network switches, including unmanaged, lite managed, and fully managed options. These switches are designed to provide reliable, high-speed Ethernet connectivity for industrial environments, and can help expand and stabilize your automation network infrastructure with ease.

When you combine a Maple System Industrial Panel PC or Box PC with award-winning Aveva Edge Software you will have one of the most powerful industrial control, monitoring, and SCADA tools available. Maple’s award-winning touchscreens offer everything you need in an industrial computer, including high-quality components, impressive connectivity, fast processors, and clear high-contrast displays.

AVEVA™ Edge Overview

AVEVA Edge, formerly known as Indusoft Web Studio, is a powerful HMI/SCADA software package for a wide range of industrial applications.

AVEVA is a global leader in industrial software, offering solutions for Monitoring and Control, Asset Performance Management, Intelligent Performance, and other segments. The product brand name transition from InduSoft Web Studio to AVEVA Edge marks the adoption of the AVEVA brand but also introduces our customers to the broader AVEVA ecosystem and its benefits. Even though AVEVA Edge can still be used as a stand-alone solution (HMI, SCADA, IIoT gateway), the integration with the AVEVA portfolio enables our customers to access a much broader and sophisticated set of solutions for their needs. The brand alignment is just one factor that will facilitate our customers realize the benefits from using AVEVA Edge as an integral part of the AVEVA portfolio.

Aveva Edge development software supports Windows Operating Systems and is used to create the project that resides on the operator interface and operates the target industrial system. In addition to the Panel PC and the user-created application project, each target system requires one Aveva Edge runtime license in order to operate the project.

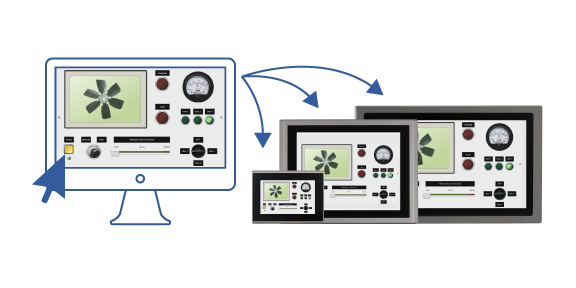

Aveva Edge is completely scalable, meaning that an application built for a Windows mobile device can be scaled up to run on a Windows Server edition, and vice versa. Aveva Edge embedded is a full featured HMI SCADA software with a small footprint.

Web Studio to Aveva Edge

- Projects built with any version of InduSoft Web Studio are 100% compatible with AVEVA Edge (no conversion required).

- Projects built with AVEVA Edge are not compatible with InduSoft Web Studio.

- Customers can request a replacement of licenses for InduSoft Web Studio to AVEVA Edge.

- Customers can upgrade licenses for older versions of InduSoft Web Studio to newer versions of AVEVA Edge paying only the version upgrade fee.

- Customers with a license under a valid (not expired) maintenance program (AMSP for InduSoft Web Studio or CF for AVEVA Edge) are eligible to version upgrades at no additional cost.

Try Before You Buy

Download a free evaluation of Aveva Edge before you buy it. Aveva Edge’s evaluation version gives you 40 hours of (non-continuous) full access to all the features of the software. Create your own application and experiment to your heart’s content – even download projects and run them on a target system during the evaluation period. After taking the software for a test drive, Maple Systems can help you determine exactly what Aveva Edge configuration you need.

Features of AVEVA™ Edge® (formerly Web Studio)

Alarms and Events

Alert operators to critical conditions using the alarm feature:

- Organize by groups and priority

- Save alarm data to disk (including Compact Flash)

- Alarm format can be customized

- Keep track of total numbers of alarms and unacknowledged alarms

- Send emails about alarms

Animation

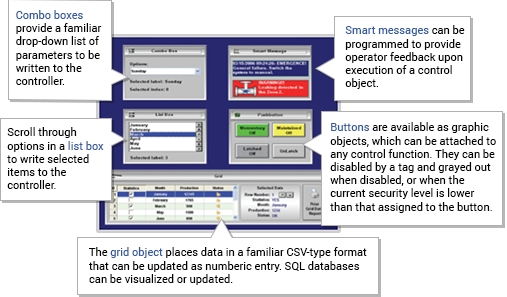

Take command over graphics in a user friendly and intuitive interface. Paste images, and even rotate dynamically using custom rotation points. Fill bar graphs with color or adjust the scale of objects with easy-to-use configuration. Other animations include ‘command’ (for touch, keyboard and mouse interaction), hyperlink, text data link, color, resize, transparency, and position.

Bar Graphs

Versatile bar graphs can be customized to display meaningful data such as tank levels. Bar graphs can use color, and can move up, down, left, or right. You may also configure an ellipse or rectangle as a bar graph.

Business Intelligence

Transform raw data into meaningful information. Design custom dashboards in minutes with the Aveva Edge (formerly InduSoft Web Studio).

Database

Connect to any SQL database (Microsoft SQL, MySQL, Sybase, Oracle), or Microsoft Access or Excel, and ERP/MES systems (including SAP), even from Windows Embedded Compact Edition. The flexible built-in interface doesn’t require knowledge of SQL. A patented solution allows for communication with SQL and relational databases running on any supported platform.

Drivers

Use over 250 native communication drivers for PLCs, temperature controllers, motion controllers, bar code/2D/RFID readers, and many others such as MQTT (with Sparkplug B) and robots. Use native drivers, connect to an OPC server, or use AVEVA driver toolkits even to build your own drivers. Save time with comprehensive tag integration.

Send email (with attachments) or text messages that can be accessed from mobile devices. Get real-time information on alarms, process values, and other events. Full runtime supports SSL encryption.

Events

Ensure traceability for operator-initiated actions or internal system activities. Log events such as security system changes (user logon or off), screen open/close, recipe/report operations, system warnings, and any tag value changes, including custom messages.

FDA Traceability

Take advantage of built-in functionality to create 21 CFR part 11 compliant projects with traceability and e-signatures. These features are often used for pharmaceutical and food applications but can be used for any application where traceability is a requirement.

FTP

Automatically upload or download files during runtime to/from remote storage locations using the FTP protocol and flexible scripting functions. Configure FTP via scripting or the included interface.

Graphics and Design Tools

Create screens to meet any application requirement using the tools in our graphic editors. Combine, animate objects to create any functionality required. Use the hundreds of symbols included Industrial Graphics libraries, and easily make projects across a product line share a consistent “look and feel”.

Historian

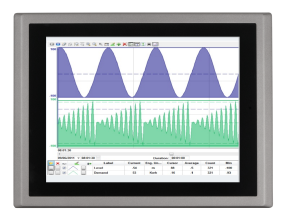

The trend history is optimized, featuring data decimation designed to load millions of values from SQL Relational Databases. Easy to use tools provide quick access to Statistical Process Control (SPC) values without any need for programming. InduSoft Web Studio offers add-on integration with the AVEVA™ Historian and support for AVEVA™ Insight.

Import Wizards

Convert whole applications from FactoryTalk™ ME/SE, PanelMate™, or PanelBuilder™32. Save time in conversion from a previously designed application to an Aveva Edge (formerly InduSoft Web Studio) application. Additional license required.

Intellectual Property Protection

Protect your intellectual property with just a few mouse clicks. Screens, documents, scripts and worksheets can be individually password protected. This prevents unauthorized viewing or editing of your project or application.

JavaScript Custom Widgets

Custom Widgets integrate 3rd party, reusable JavaScript, HTML5, and CSS interfaces properties and events to expand and enhance the graphical interface.

Mobile Access

A multiple document interface for this thin client allows you to access your graphical interface from any device with a browser that supports HTML5, such as iPads, iPhones, Android devices, Windows devices, and others. Aveva Edge includes support for Industrial Graphics and all native objects and allows you to integrate 3rd party web-based controls.

Multi-Language

Develop your application in one of many development languages, including English, Portuguese, German, French, Russian, Chinese Traditional and Simplified, Japanese and Spanish, or use translation tools to switch the runtime to any language. Aveva Edge offers automatic font replacement based on the language selected.

Multi-Touch Interface

Develop applications for touch screen devices. Aveva Edge’s multi-touch interface allows development for any touch-screen enabled device. Use familiar, modern interface gestures, like pinch zooming and panning. Scroll through alarms using swiping gestures; inertia in the multi-touch interface offers a comfortable user experience. Rotate graphics, dock screens, and take advantage of features like dual-touch command. Swipe gestures to change screens or other commands.

.NET and ActiveX

Use 3rd party controls to enhance your project. Aveva Edge is a container for ActiveX and .NET controls, allowing you to add functionality such as browsers, media players, charting, live streaming from cameras, and other ActiveX or .NET controls.

OEM

Aveva Edge can be customized for OEMs who want to offer pre-installed HMI or SCADA software on their hardware, or for OEMs who want to add value to their machines by offering remote monitoring, maintenance, or customizable applications.

OPC

Aveva Edge provides native OPC interfaces, such as OPC UA (Client/Server), OPC DA (Client/Server), OPC XML (Client), and OPC HDA (Server). OPC UA and OPC DA also offers native redundancy configuration and tag integration for OPC DA and OPC UA Servers.

PDF Export

Send Alarms, Reports, or any file to a production supervisor, quality manager, or maintenance staff using the included PDF writer.

Recipes

Save time and maintain consistency by automating part parameters or production quantities with flexible recipe management tools. Options including loading directly to PLC or edit before committing to PLC.

Redundancy

For critical applications where data is vital, Aveva Edge supports web server, database and overall system redundancy to protect your information.

Reports

Create clear, concise reports in plain text, RTF, XML, PDF, HTML, and CSV or integrate with Microsoft Office programs such as Excel. Get the data you need, in the format you need it, to make informed decisions, fast. AVEVA has also partnered with Ocean Data Systems to offer further reporting capabilities through Dream Report *.

Run-Time

When ordering Aveva Edge, one runtime license is included with the development software. Additional runtime licenses are required for every Industrial PC.

- The development software is used to create projects that can be downloaded to a Maple Systems Panel PC.

- The runtime license allows a Aveva Edge project to run on a Maple Systems Industrial Panel or Box PC running a Windows Operating Systems.

Scalable

Use the same development environment to design and deploy projects to a wide range of platforms, such as Linux, Windows Embedded Standard, Windows Embedded Compact, Windows 8., Windows 10, Server 2012, Server 2016 and Server 2019 editions.

Scheduler

Schedule application behavior triggered by tag changes, date/time, frequency, or any trigger. Use this for simulation, to trigger reports or other functionality at a particular time of day, or even to trigger driver worksheets to read/write at a scan rate you choose.

Scripting

Three powerful scripting languages are supported; built-in AVEVA functions, Industrial Graphics Quick Script and standard VBScript. Take advantage of widely available resources for VBScript. The scripting languages can be used simultaneously to give you the functionality you need, even from thin clients. Script debugging tools for the native VBScript editor include breakpoints, and a variable watch list to improve scripting productivity.

Security

Aveva Edge includes support for group and user accounts, e-signatures, and traceability. Integrate your project to the Active Directory (Users and Groups).

Standards

Use common standards to develop applications that are compatible with TCP/ IP, .NET, ActiveX, OPC (client and server), ADO/ODBC, COM/ DCOM, OLE, DDE, XML, SOAP, and HTML5.

Symbols

The included libraries feature push buttons, pilot lights, tanks, sliders, meters, motors, pipes, valves and other common objects. Use the 1,000+ included symbols in your project, modify existing symbols to suit your needs, or create your own from scratch. Aveva Edge supports 3rd party symbol libraries and graphic tools.

Templates

Aveva Edge has several plug and play templates available including: Andon, OEE, and PackML.

Tag Database

Aveva Edge features an object-oriented database with boolean, integer, real, strings, arrays, classes (structures), indirect tags and included system tags. Built-in functions allow you to create, delete, or modify the tags database settings during the runtime. This feature increases the flexibility to design generic templates that can be easily customized to each project, even during the runtime. Aveva Edge also offers tag integration from a wide range of PLCs, including Schneider Electric.

Thin Clients

Provides remote access to the application from other devices. Supports three types of remote application viewers: Secure Viewer, Microsoft Internet Explorer-based browser, and Studio Mobile Access (SMA) for smart phones and tablets.

Trends

Real-time and Historical trends, and SPC functionality are supported. Log data in binary format, or to any local or remote SQL database and optionally to AVEVA Historian (additional licenses required). Color or fill trends with graphic elements to enhance clarity of data. Date/Time based or numeric (X/Y plot) trends give you the flexibility to display information that best suits your application. Aveva Edge supports vertical and horizontal trending.

Troubleshooting

Quickly debug and verify a project using local and remote tools for troubleshooting, including status fields, HTML5 based Watch Window for IoT View, Watch Window and LogWin. Capture screen open and close times, see communications in real-time, messages related to OPC, recipes/reports, security, database errors and even custom messages. Finish your project quickly using these powerful tools.

XML Screen Toolkit

Modify or create screens during the runtime or import screens that you have created. This feature is available as an add-on.

XY Plots

Interpret data using customized XY plots that plot one value against another

Web Solutions

Aveva Edge provides a state-of-the-art web solution, the ability to view screens and monitor online history data from the Industrial Panel PC on any remote station (from PDAs to PCs) using Microsoft Internet Explorer.

- Send commands and set points to the Industrial Panel PC from the web thin client using optional security restrictions

- Enable automatic emails from the Industrial Panel PC to a web thin client

- Supports Active X controls for easier interfacing with web thin clients

Technical Support

Aveva Edge is a 3rd party software that Maple Systems offers with our Industrial PCs, as such, we provide tier 1 technical support as a courtesy to our customers.

Tier 1 support is assistance with basic issues that customers may have, such as issues with the product installation, the product licensing, and any questions that can be answered using the product manual or the AVEVA knowledge database.

- Product Manual: Refer to the Aveva Edge: User Guide for common questions

- Aveva | Customer Service Portal- Knowledge Base. Registration is required to access to Knowledge Base. To register https://om.aveva.com/softwarewebID/

If additional support is required, please start a support case with our team at sales@maplesystems.com and allow additional time for processing Aveva support tickets.

Contacting Aveva Technical Support Directly

- Live chat from the AVEVA Edge page https://www.aveva.com/en/support-and-success/support-contact/ (just click on the chatbot icon)

- Phone:

- (+1) 949-639-8500

- (+1) 800-966-3371

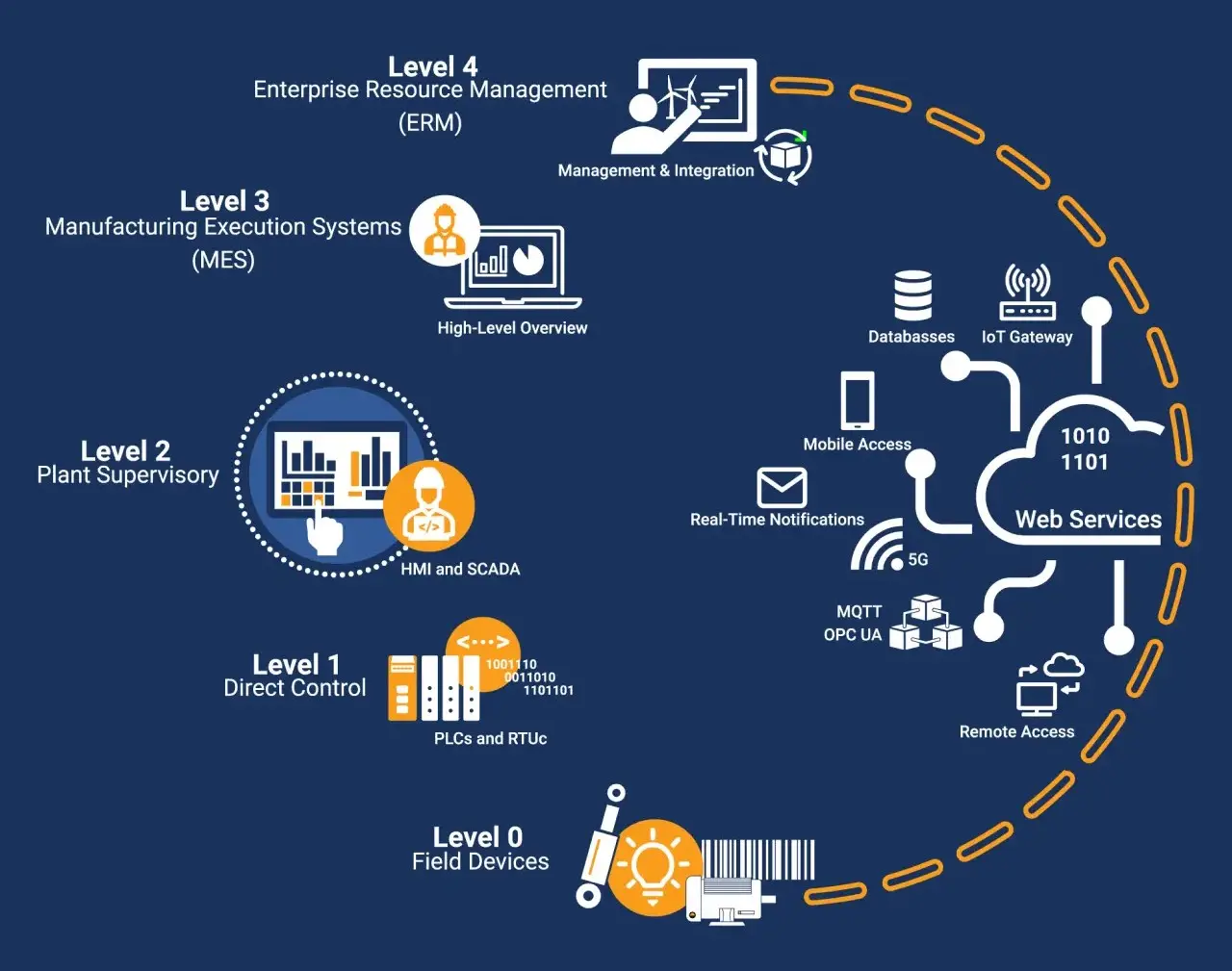

SCADA

SCADA Systems offer an opportunity for any network of devices to communicate the necessary information for more advanced monitoring, alarm detection, management, and more.

As you can imagine, SCADA systems can take on a wide range of functionality, complexity, hardware, and software solutions – and AVEVA Edge delivers the capability to literally accomplish any control/monitoring/SCADA task and it can be applied in an infinite number of ways.

Read more about how Maple Systems can easily integrate into existing systems.

Many models of a SCADA system may vary from resource to resource. However, there are generally three levels (0-2) within a SCADA system. Each level of the SCADA system performs specific tasks and communicates with other levels for efficient monitoring and control of processes. Read More